Devices formed from a non-polar plane of a crystalline material and method of making the same

A manufacturing method and technology of crystal materials, applied in semiconductor/solid-state device manufacturing, semiconductor devices, polycrystalline material growth, etc., can solve problems such as difficulties in gallium nitride semiconductor wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

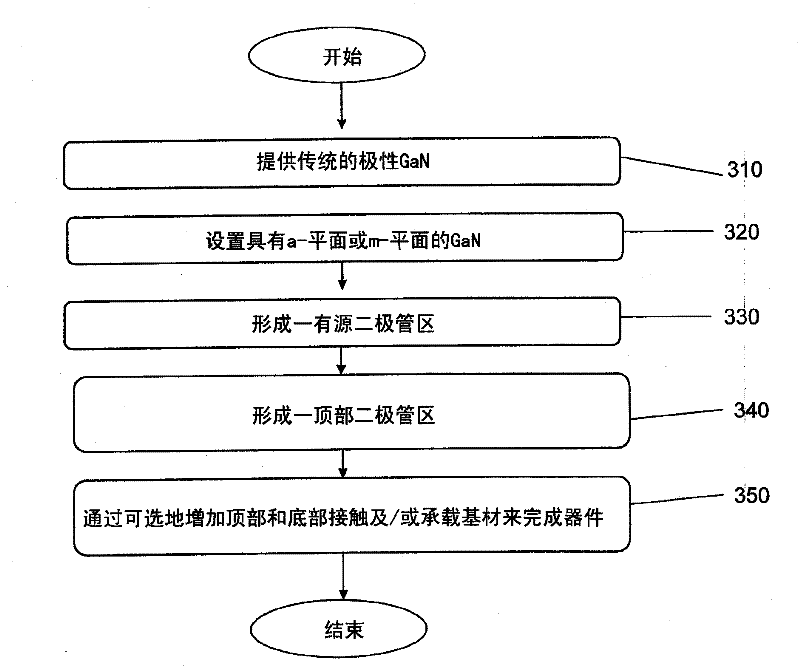

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the inventive concept will be described in detail below and various examples are shown in the drawings, wherein like reference numerals are used for like parts throughout. The embodiments described below are described by referring to the figures in order to explain the concept of the present invention.

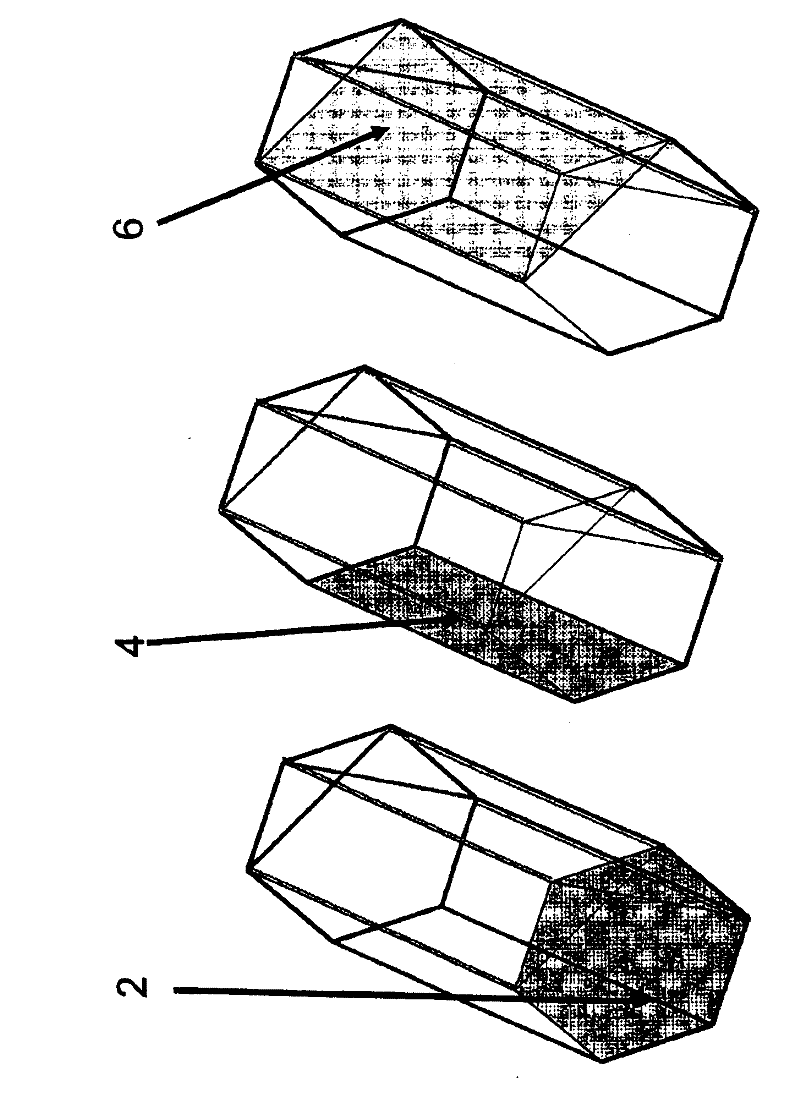

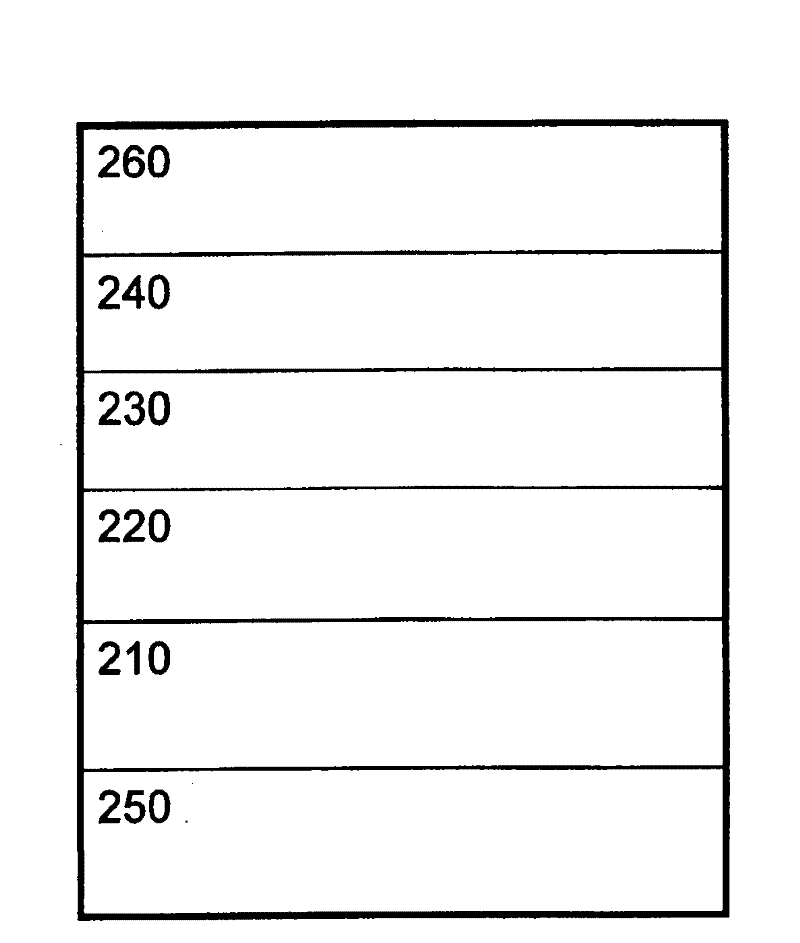

[0030] See figure 2 , a diode may include: a bottom diode region 220, an active diode region 230, and a top diode region 240, a first electrical contact 260 at the top of the device, and a second electrical contact 250 at the bottom of the device . Each zone 220, 230, 240 may comprise multiple layers. The diode can be coupled to a substrate 210 . Such as figure 2 As shown, in one embodiment, substrate 210 may be coupled between bottom contact 250 and active diode region 230 . Although figure 2 A vertical diode structure is shown, however it should be emphasized that the present invention is not limited to this structural arrangement and that othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com