Hydroxyapatite, sodium hyaluronate and konjac glucomannan composite material and preparation method thereof

A technology of konjac glucomannan and sodium hyaluronate, which is applied in the field of biomedical materials, can solve problems such as poor mechanical properties, limited application, and high brittleness, and achieve the effects of meeting requirements, improving mechanical properties, and promoting bone growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

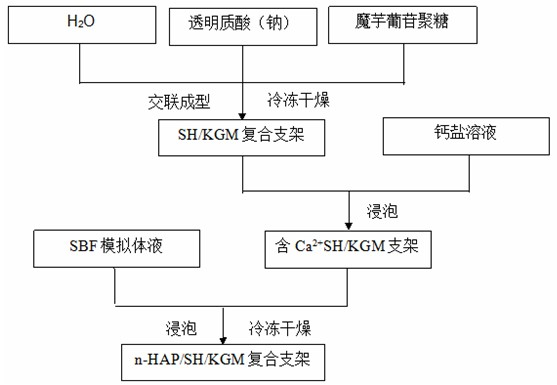

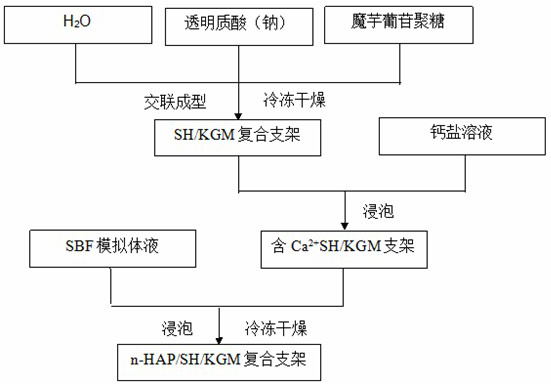

[0026] Example 1: see figure 1 , the preparation method of this hydroxyapatite, sodium hyaluronate and konjac glucomannan composite material is:

[0027] (1) According to the mass ratio of sodium hyaluronate and water of 1:2000, dissolve sodium hyaluronate in water, stir it to fully dissolve, and then add alkaline solution into the solution; the concentration of alkaline solution is 0.1vol % NH 3 ·H 2 O solution, the volume ratio of alkaline solution to water is 1:800.

[0028] (2) Cross-linking: According to the mass ratio of sodium hyaluronate to konjac glucomannan of 1:8, konjac glucomannan was added to the product obtained in step (1), and stirred until it was in a gel state.

[0029] (3) Seal the product obtained in step (2) and mature it in a water bath at a temperature of 90°C for 12 hours, take out the product, and then lower the temperature of the water bath to 15°C, then place the product in a water bath to dealkalize until the product solution The pH value was 7...

Embodiment 2

[0033] Example 2: see figure 1 , the preparation method of this hydroxyapatite, sodium hyaluronate and konjac glucomannan composite material is:

[0034] (1) According to the mass ratio of sodium hyaluronate to water is 1:667, dissolve sodium hyaluronate in water, stir to make it fully dissolved, and then add alkaline solution into the solution; the concentration of alkaline solution is 0.8vol % NH 3 ·H 2 O, the amount added is 1:500 according to the volume ratio of alkaline solution and water.

[0035] (2) Crosslinking: According to the mass ratio of sodium hyaluronate to konjac glucomannan of 1:25, konjac glucomannan was added to the product obtained in step (1), and stirred until it was in a gel state.

[0036] (3) Seal the product obtained in step (2) and mature it in a water bath at a temperature of 70°C for 24 hours, take out the product, and then lower the temperature of the water bath to 30°C, then place the product in a water bath to dealkalize until the product so...

Embodiment 3

[0041] Embodiment 3: see figure 1 , the preparation method of this hydroxyapatite, sodium hyaluronate and konjac glucomannan composite material is:

[0042] (1) According to the mass ratio of sodium hyaluronate and water of 1:400, dissolve sodium hyaluronate in water, stir to fully dissolve, and then add alkaline solution into the solution; the concentration of alkaline solution is 1vol% NaOH solution, the amount added is 1:80 according to the volume ratio of alkaline solution to water.

[0043] (2) Cross-linking: According to the mass ratio of sodium hyaluronate to konjac glucomannan of 1:200, konjac glucomannan was added to the product obtained in step (1), and stirred until it was in a gel state.

[0044] (3) Seal the product obtained in step (2) and mature it in a water bath at a temperature of 50°C for 48 hours, take out the product, then lower the temperature of the water bath to 50°C, and put the product in a water bath to dealkalize until the product solution The pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com