Method for treating waste liquid and waste gas produced by fish meal processing

A technology for waste gas treatment and waste liquid treatment, which is applied in animal processing wastewater treatment, chemical instruments and methods, separation methods, etc. It can solve problems such as corruption, stench, and restriction of economic development, and achieve simple methods, energy saving, and automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] Use horizontal centrifugal equipment and disc centrifugal equipment to separate the oil in the squeezed liquid from water and solids, so that the water in the oil is less than 1%, and the impurities are less than 0.5%, forming crude fish oil and then refining; after separating the water and the oil The solid matter is concentrated in the next process. Heat and concentrate the above-mentioned water containing 20% solids, control the temperature at 70°C to vacuum, vacuum degree: -0.095Mpa, carry out multi-effect concentration, and stop the concentration when the solid content of the concentrated solution reaches 55%. Spray the above concentrate on the press cake and dry it together.

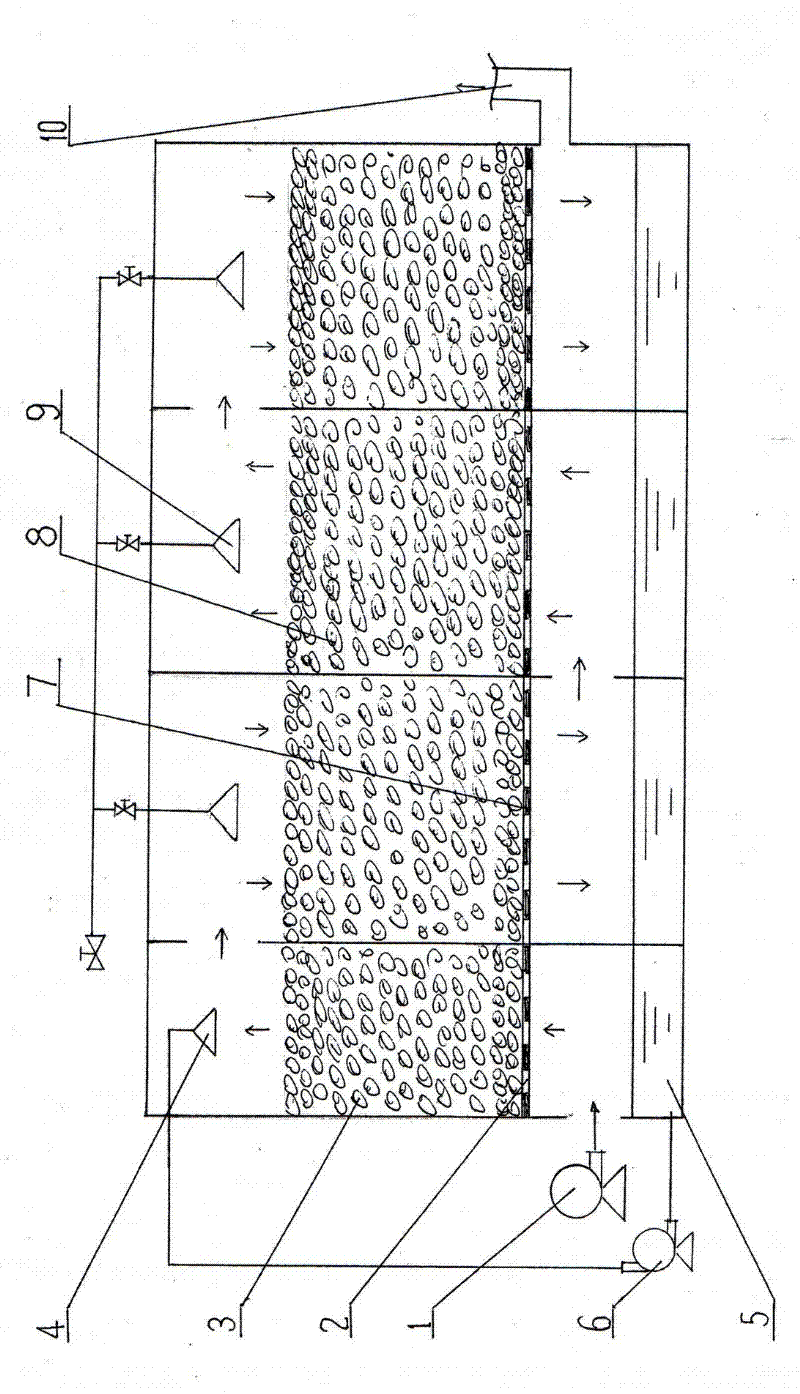

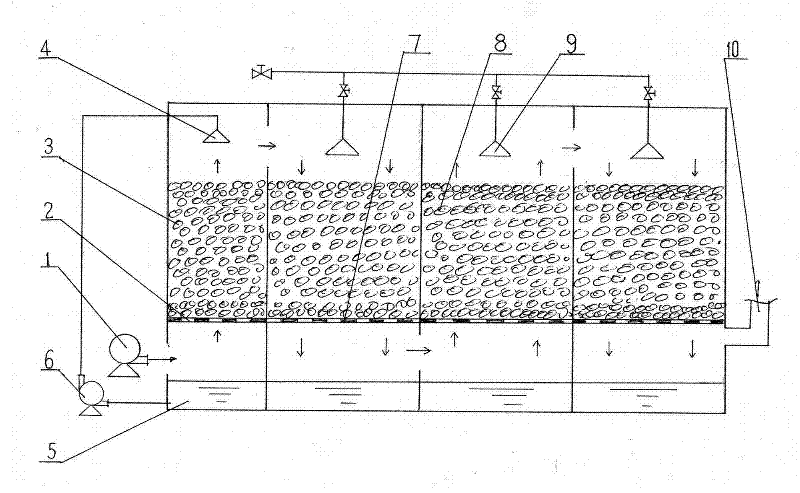

[0034]The above cooking, drying, concentration and amine removal equipment are all equipped with a fishmeal particle trap and a waste gas collector. The fishmeal particle trap first separates and recycles the small solid particles in the waste steam, and the gas coming out of the trap is ...

example 2

[0038] Use horizontal centrifugal equipment and disc centrifugal equipment to separate the oil in the squeezed liquid from water and solids, so that the water in the oil is less than 1%, and the impurities are less than 0.5%, forming crude fish oil and then refining; after separating the water and the oil The solid matter is concentrated in the next process. Heat and concentrate the above-mentioned water containing 11% solids, control the temperature at 100°C to vacuum, vacuum degree: -0.075Mpa, carry out multi-effect concentration, stop concentrating when the solid content of the concentrated solution reaches 45%. Spray the above concentrate on the press cake and dry it together.

[0039] The above cooking, drying, concentration and amine removal equipment are all equipped with a fishmeal particle trap and a waste gas collector. The fishmeal particle trap first separates and recycles the small solid particles in the waste steam, and the gas coming out of the trap is The exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com