Alkylation method

A technology of alkylation and catalyst, applied in the field of isoparaffin-olefin alkylation, which can solve the problems of high energy consumption of the process system, fast catalyst deactivation, and low service life, and achieve the effect of low energy consumption of the process system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

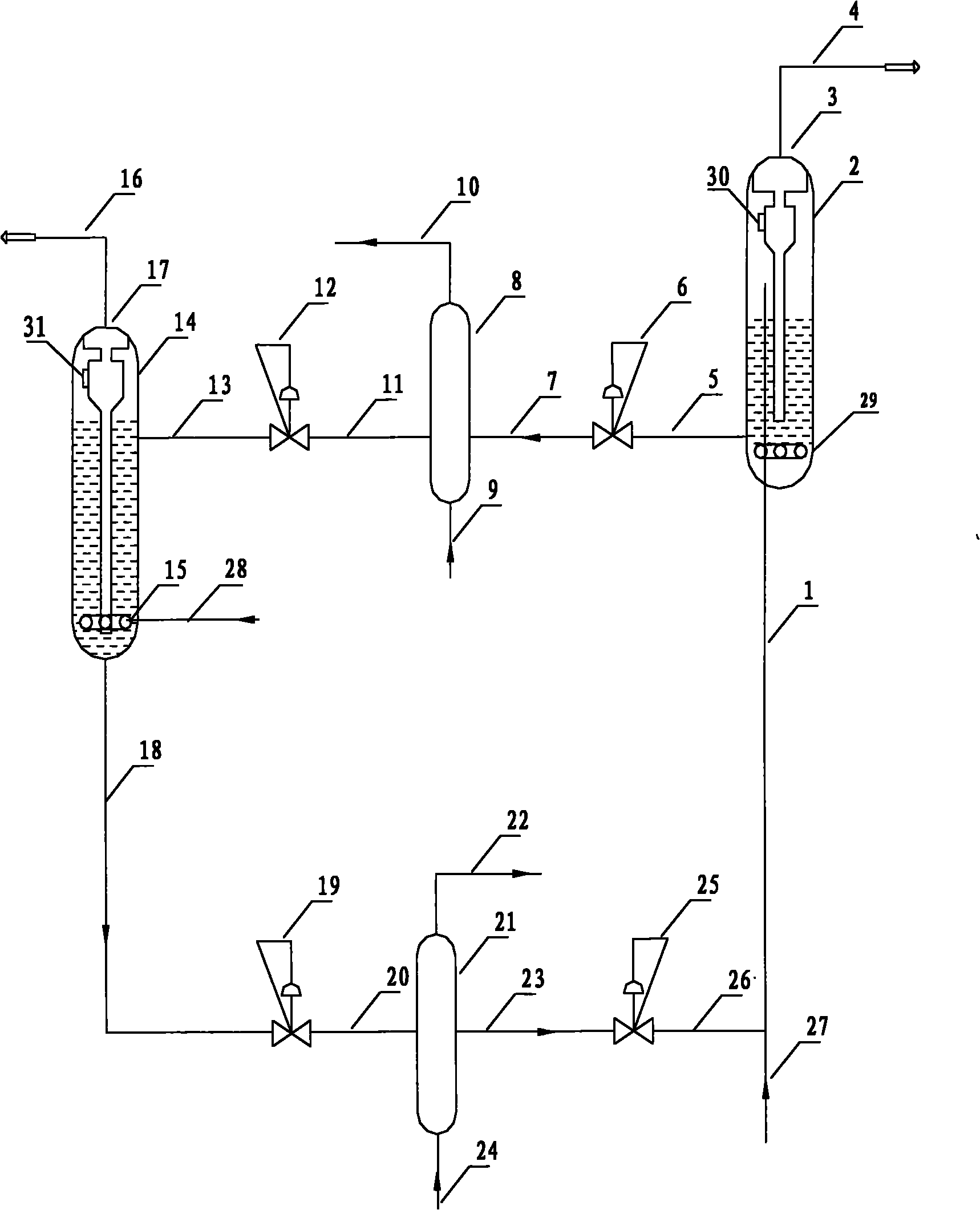

[0038] like figure 1 As shown, the catalyst from the supercritical catalyst regenerator 14 is pressurized or decompressed through the dosing surge tank, and then the catalyst flow is controlled by the slide valve 25, and is transported to the bottom of the riser through the pipeline 26 driven by isoparaffins. Mix with the olefins entering from the pipeline 27 according to a certain ratio, and react in the riser reactor 1. The product, unreacted reactants and catalyst enter the settler 2 together, and the liquid product passes through the inlet 30 through the cyclone separator 3 and the solid catalyst. After separation, the product flows out from the product outlet 4 and enters the product separation system to separate the target product from unreacted reactants, and the unreacted reactant isoparaffins are returned for use. The outflow of the catalyst and the residence time of the catalyst in the settler are controlled by the slide valve 6, and the catalyst deactivated by the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com