Underground flow control valve based on fiber bragg grating sensing detection

A technology of flow control valve and optical fiber grating, which is applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and production, etc., to achieve the effect of reducing driving force, good repeatability, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

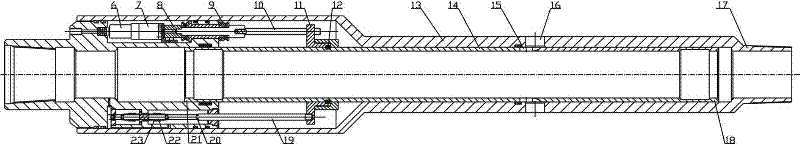

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

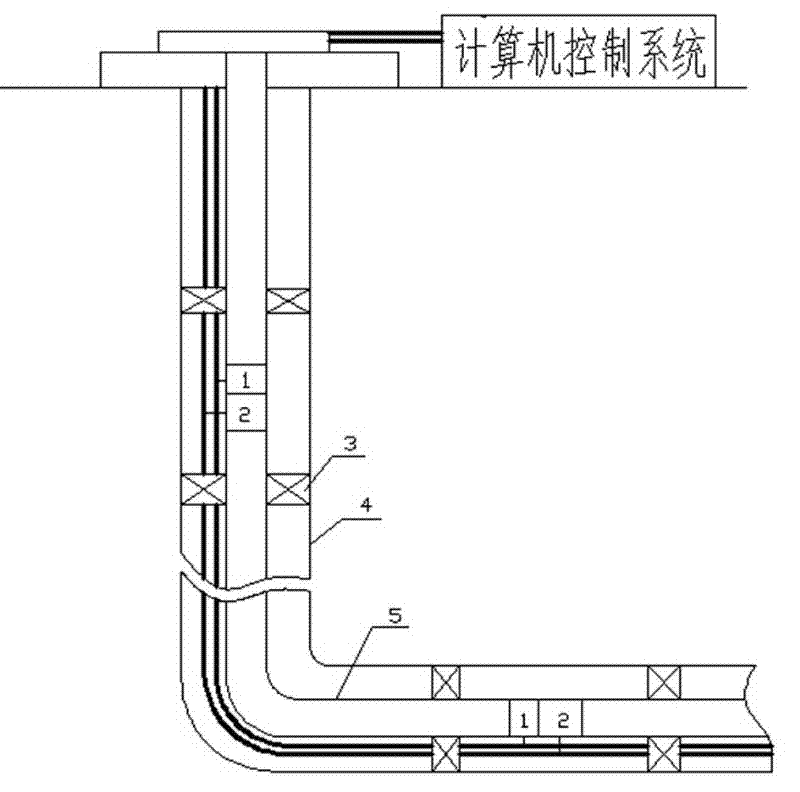

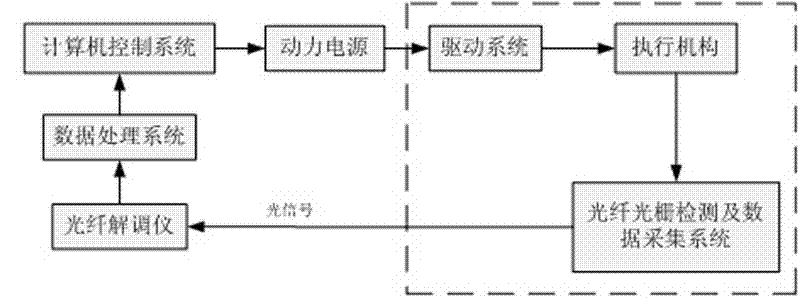

[0026] The present invention provides a downhole flow control valve based on fiber Bragg grating sensing detection, and its overall structure schematic diagram is as follows figure 1 Shown: It mainly includes computer control system, power supply, motor drive system 1, actuator and fiber grating detection system, motor drive mechanism, actuator and fiber Bragg grating detection mechanism to form a flow control valve 2, wherein the computer control system on the ground and the fiber grating detection system form a flow control valve 2. The downhole signal line (electrical cable and optical cable) is connected, and the downhole signal line is put downhole along with the casing 4, and the packer 3 acts between the casing 4 and the tubing 5, and its function is to isolate each oil layer. The cable between the packers is used for the motor drive system 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com