Scale-span in situ micro-nano stretching/compressing hydraulic drive testing device under microscopic assembly

A driving test, micro-nano technology, used in measuring devices, using repetitive force/pulse force to test the strength and strength characteristics of materials, etc., can solve the problems of complex structure, poor compatibility, high cost, etc., to achieve small size and application range. Extensive, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

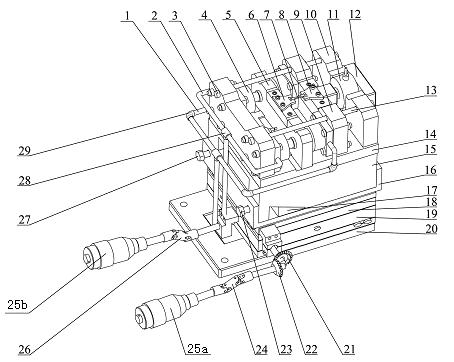

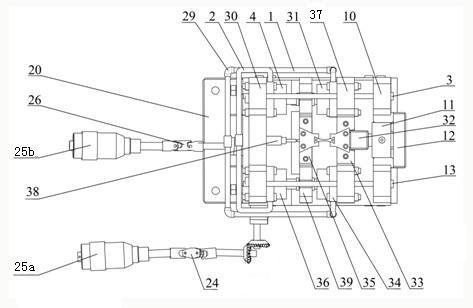

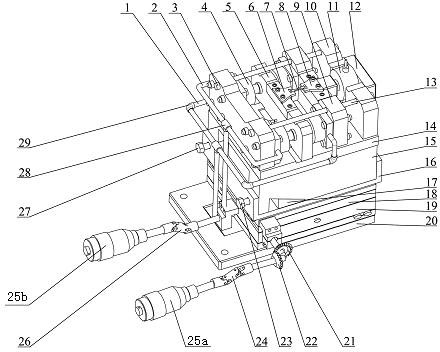

[0028] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0029] see figure 1 and figure 2 , the under-scale and in-situ micro-nano tension / compression hydraulic drive test device for micro-components of the present invention includes a hydraulic precision drive control unit, a test execution unit, a three-degree-of-freedom adjustment workbench, a test detection unit, a connection and a support unit; The hydraulic precision drive control unit and the test execution unit are: the output ends of the servo hydraulic cylinders I~IV4, 36, 31, and 34 are respectively connected to the mobile frame group 5, and the mobile frame group 5 is slidably connected to the base plate 14 , under the action of the external hydraulic servo control system, the servo hydraulic cylinders I, II4, 36 move in opposite directions to the servo hydraulic cylinders III, IV31, 34, and push the mobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com