Layered redundancy automatic monitoring system of field bus type marine engine room

A bus-type, ship-based technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problem of poor maintainability and scalability, low reliability, and lack of comprehensive redundancy in the bus-type ship engine room monitoring system and other issues to achieve good maintainability, scalability, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

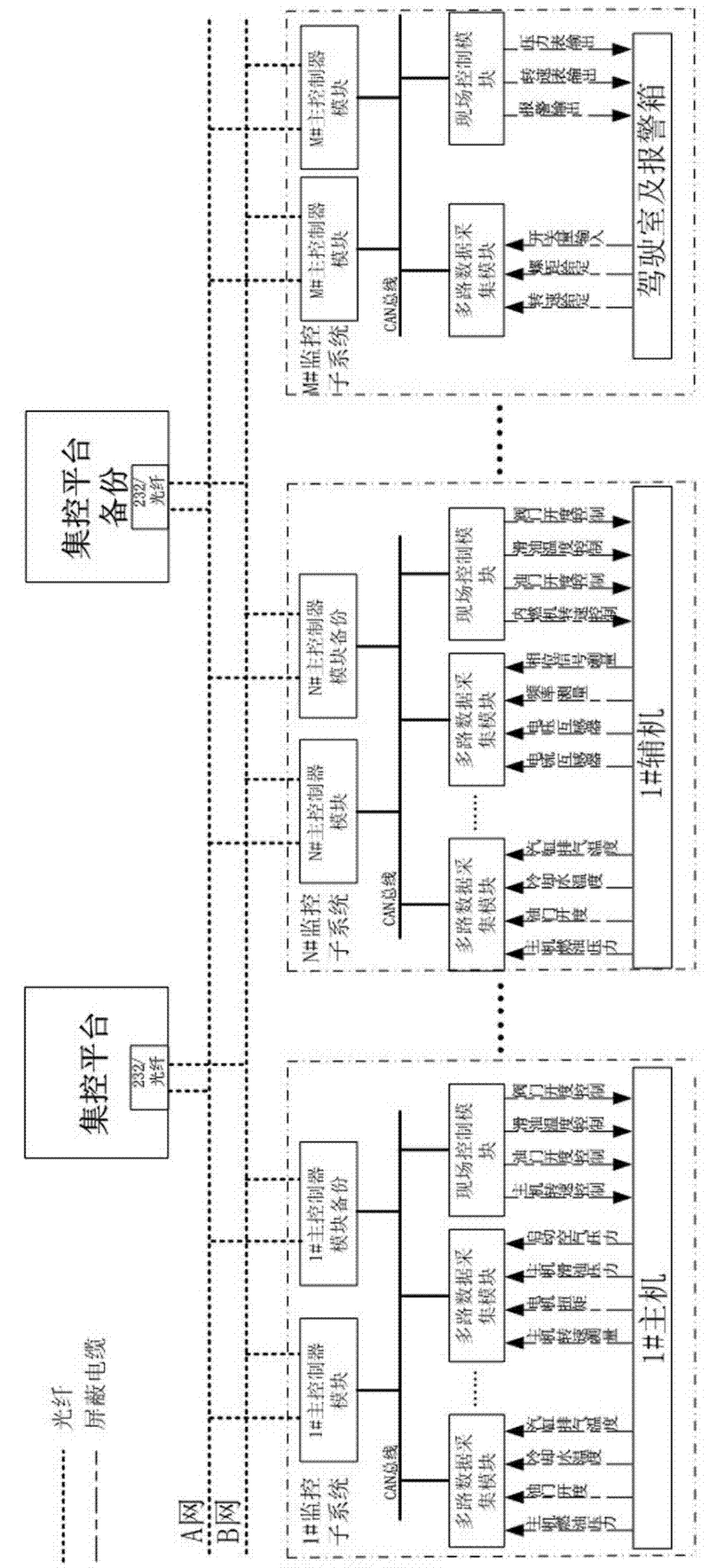

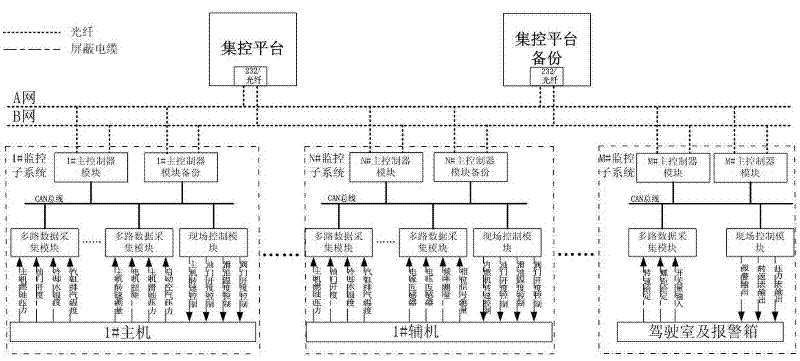

[0021] figure 1 It is a schematic diagram of the framework of the layered redundant fieldbus type ship engine room automatic monitoring system of the present invention. The system consists of a monitoring platform and multiple monitoring subsystems. The monitoring subsystem is composed of a main control module, data acquisition module and on-site control module. The main control module, data acquisition module and control module are connected by CAN bus; the monitoring subsystem realizes information interaction with the monitoring platform through optical fiber.

[0022] The monitoring subsystem independently monitors a main diesel engine, an auxiliary engine or a cab control device.

[0023] Among them, in the main engine monitoring subsystem, the data acquisition module measures the fuel pressure, throttle opening, cooling water temperature, cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com