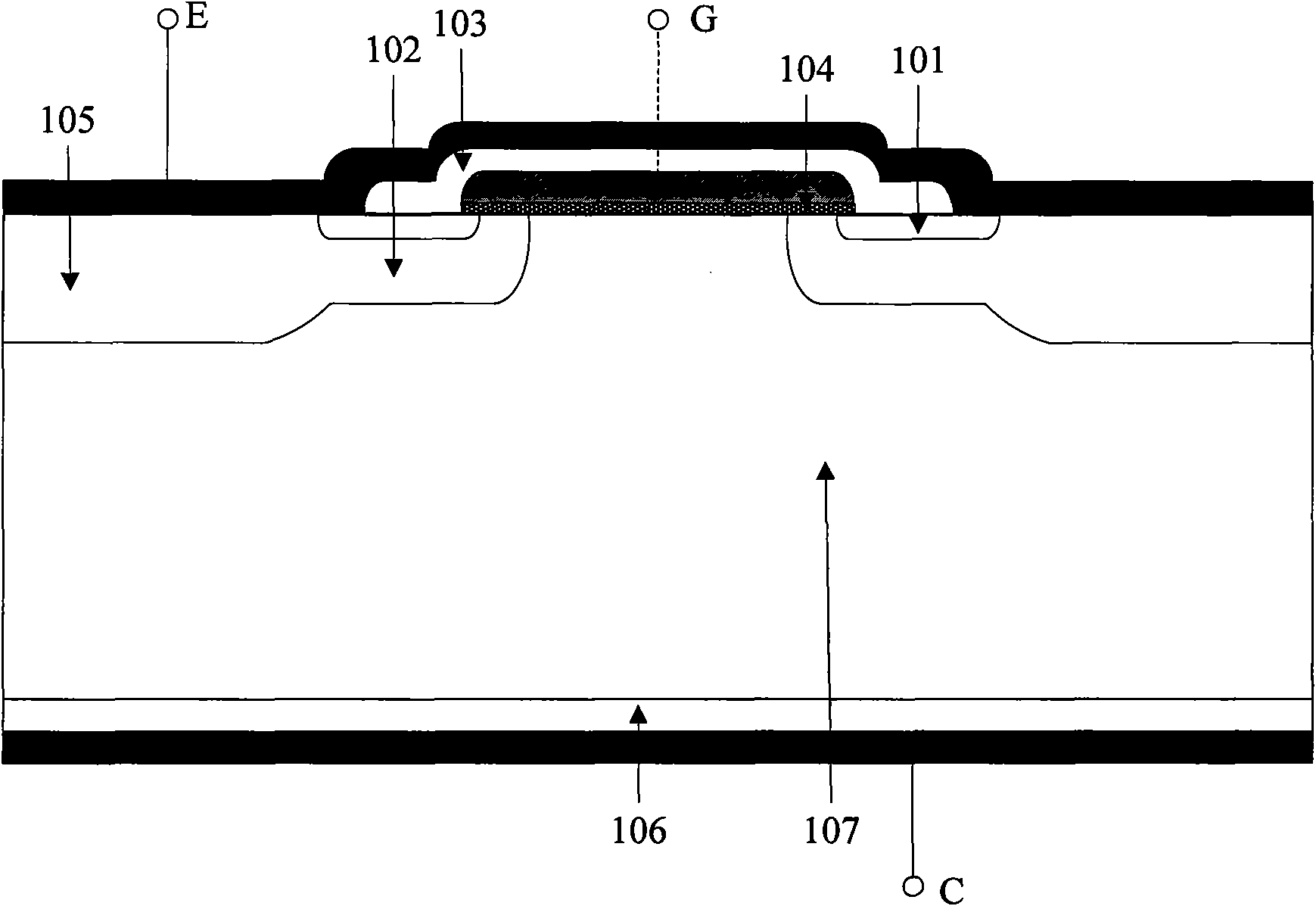

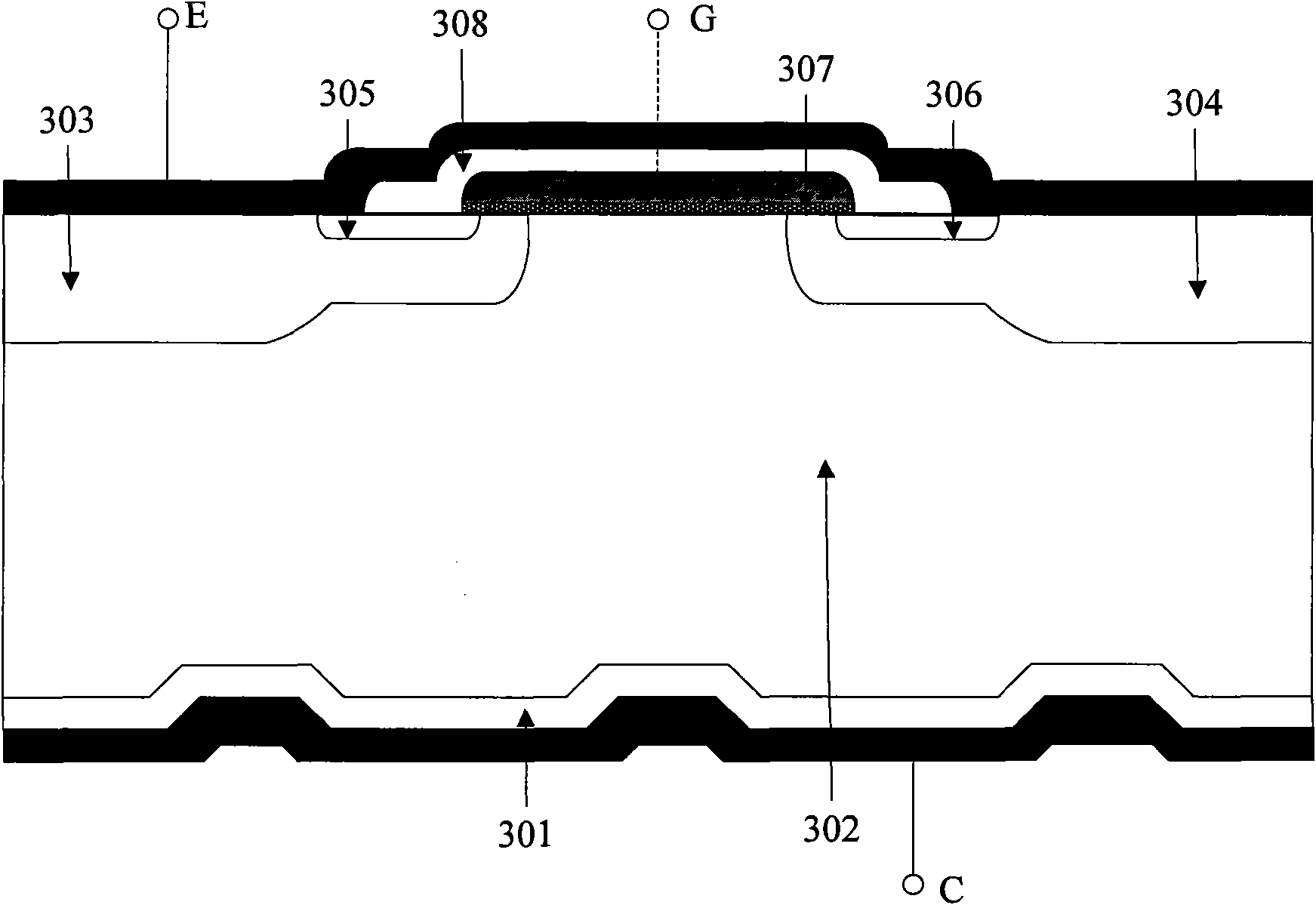

IGBT with back reinforcing structure and fabrication method thereof

A technology of enhanced structure and back injection, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reduced forward voltage and high forward voltage drop of IGBT

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

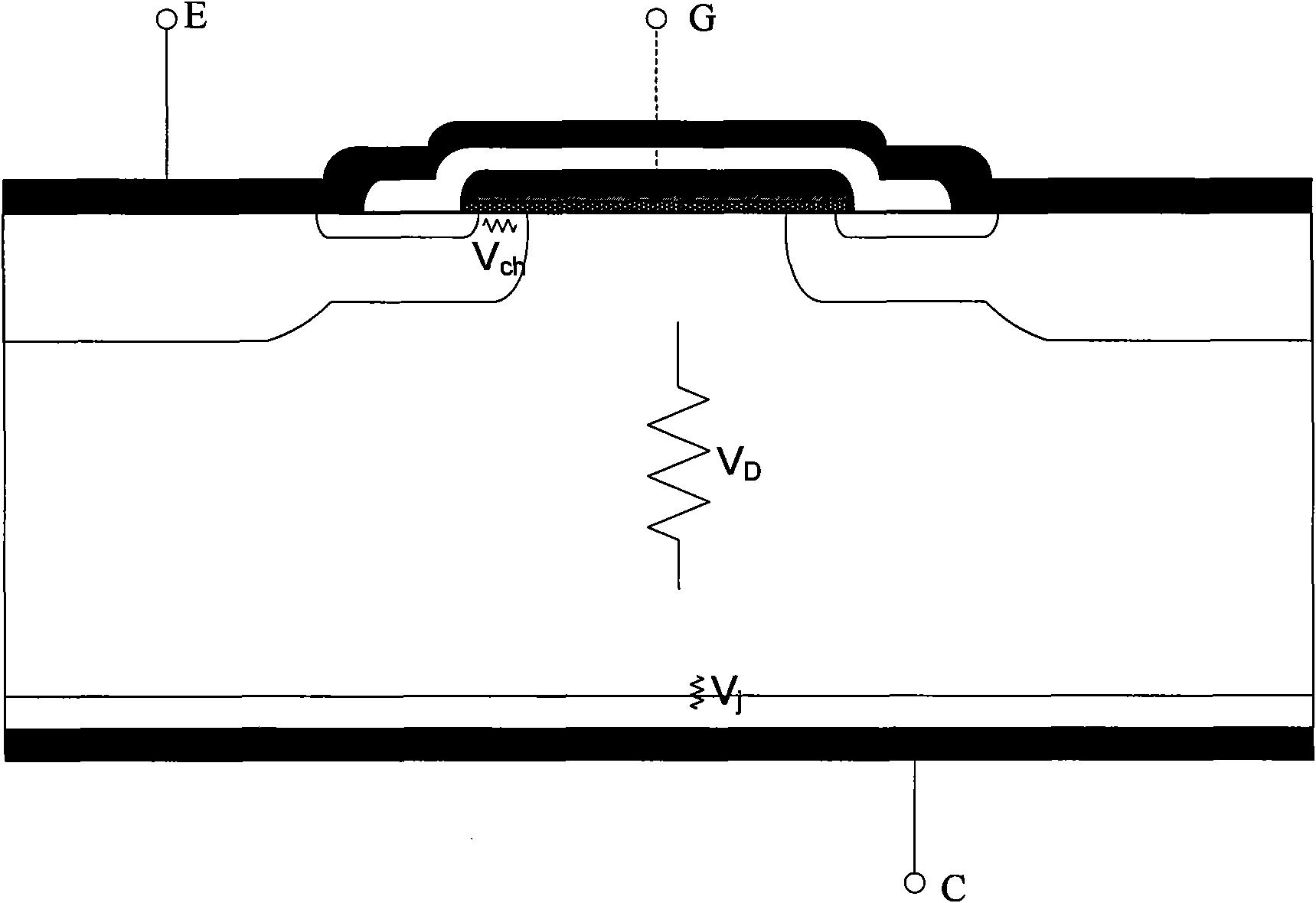

[0023] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0024] The conductance modulation effect in the IGBT is a phenomenon in which the conductance of the base region increases when the P+NP bipolar transistor operates under the condition of large injection, and it is also called the conductance modulation effect of the base region. For P+NP transistors, when the emitter junction voltage is large and a large number of minority carriers—holes are injected into the base region, there are correspondingly a large number of majority carriers—electrons in the base region. Caves have the same concentration gradient. This is equiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com