Mushroom bag hole puncher

The technology of a fungus bag and a body is applied in the field of edible fungus production, which can solve the problems of iron round steel material easy to rust, wooden sticks easy to breed miscellaneous bacteria, etc., to achieve the effect of convenient cleaning and storage, and improving the yield of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

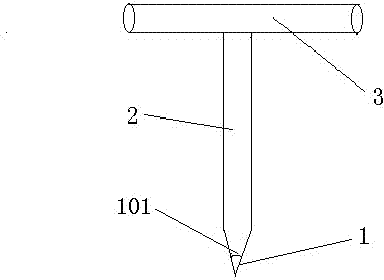

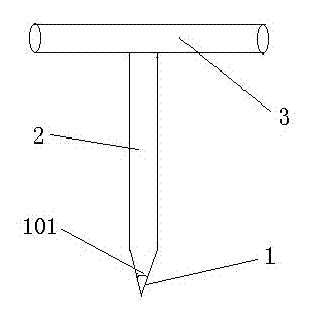

[0013] Depend on figure 1 Known, a kind of bacteria bag puncher of the present invention comprises device body 2, device tip 1 and handle 3. Its processing steps are as follows:

[0014] 1. Select 250 mm of solid stainless steel material with a diameter of 20 mm.

[0015] 2. The selected stainless steel material is cut into two sections of cylinders, one with a length of 100 mm, used as the handle 3; the other with a length of 150 mm, used as the body 2 and the tip 1.

[0016] 3. Process the tip 1 into a cone, the included angle 101 of which is less than 30 degrees, and polish the surface to be smooth.

[0017] 4. Weld one end of the body 2 with the middle part of the handle 3 to form a T-shaped punch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com