Non-focus-type photocatalytic chemical reactor

A chemical reactor and chemical reaction technology, applied in the field of light reaction, can solve the problems of reduced utilization of light, deviation of results, high operating costs, etc., and achieve the effect of increased contact area, simple structure, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

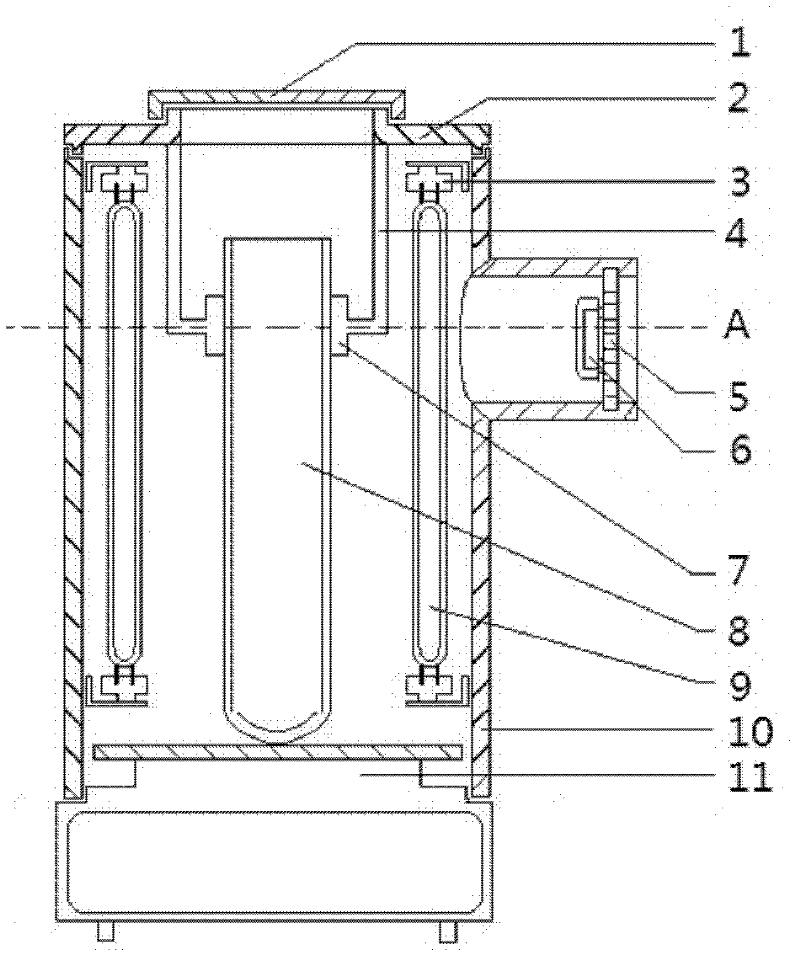

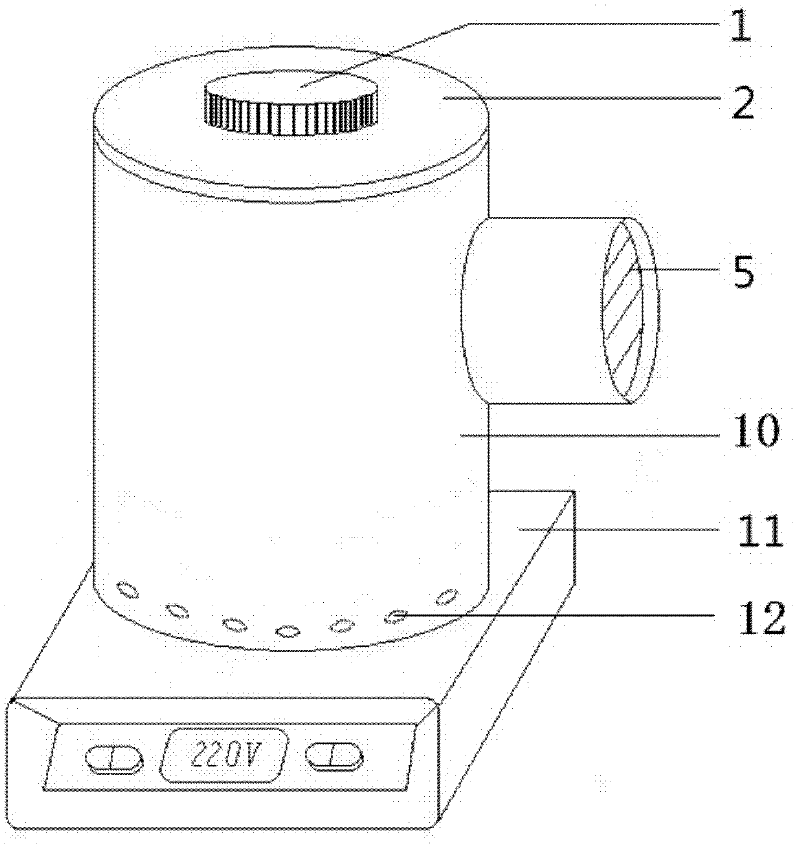

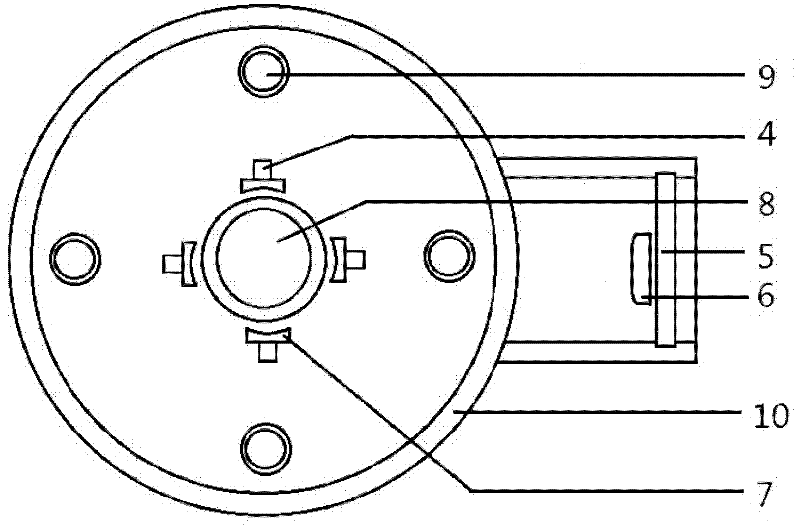

[0021] According to attached Figure 1~4 According to the structure, a photocatalytic chemical reactor is constructed. in:

[0022] The light chamber is made of PE material, the height of the cylinder is 160 mm, and the diameter is 125 mm;

[0023] Four lamp tubes 9 are used, which are evenly arranged on the side wall 10 of the lighting chamber, evenly distributed at 3 o'clock, 6 o'clock, 9 o'clock or 12 o'clock, installed vertically, and the power of the lamp tubes is 5 w;

[0024] The chemical reaction vessel placed on the vertical central axis in the light chamber is a quartz test tube;

[0025] The cooling air circulation chamber is a PVC cylinder with an axial length of 120 mm and a diameter of 90 mm, and a built-in micro fan with a power of 3W.

[0026] When using, first prepare the reactants in the chemical reaction container in the quartz test tube according to the needs of the experiment, open the small round button cover 1, and put the quartz test tube into the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com