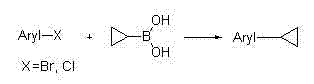

Method for synthesizing cyclopropyl alkyl aromatic compound

A technology for aromatic compounds and cyclopropane groups, applied in the field of synthesis of cyclopropane group aromatic compounds, can solve the problems of large amount of catalyst, long reaction time, harsh reaction conditions, etc., and achieves wide applicability, mild reaction conditions, and substrate range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of 3-cyclopropanylnitrobenzene

[0026] Take 0.012 mmol of ferroceneimine cyclopalladium-phosphine adduct, 0.72 mmol of cyclopropanylboronic acid, K 3 PO 4 ·7H 2 Add 1.5 mmol of O into a 10 ml Schlenk tube, and repeatedly evacuate and fill with N 2 5 times. N 2 Add 0.6 mmol 3-bromonitrobenzene and 2 ml toluene under protection. Stir at room temperature for 5 minutes, then place in an oil bath heated to 100°C, and react for 3 hours. Stop the reaction and cool to room temperature. The reaction solution was diluted with ethyl acetate, filtered, washed once with water, and the organic phase was washed with Na 2 SO 4 Dry, filter and concentrate. The residue was separated by thin-layer chromatography using ethyl acetate / petroleum ether=1 / 20 as a developing solvent to obtain 90 mg of the target product with a yield of 94%. The nuclear magnetic characterization of this compound is as follows: 1H NMR (CDCl 3 , 400MHz, ppm): δ 7.71 (d, J= 7.45 Hz, 1 H), 7.6...

Embodiment 2

[0028] Preparation of 3-cyclopropanylnitrobenzene

[0029] Take 0.012 mmol of ferroceneimine cyclopalladium-phosphine adduct, 0.72 mmol of cyclopropylboronic acid, Cs 2 CO 3 Add 1.5 mmol into a 10 ml Schlenk tube, repeatedly evacuate and fill with N 2 5 times. N 2 Add 0.6 mmol 3-bromonitrobenzene and 2 ml toluene under protection. Stir at room temperature for 5 minutes, then place in an oil bath heated to 100°C, and react for 3 hours. Stop the reaction and cool to room temperature. The reaction solution was diluted with ethyl acetate, filtered, washed once with water, and the organic phase was washed with Na 2 SO 4 Dry, filter and concentrate. The residue was separated by thin-layer chromatography using ethyl acetate / petroleum ether=1 / 20 as a developing solvent to obtain 83 mg of the target product with a yield of 86%.

Embodiment 3

[0031] Preparation of 3-cyclopropanylnitrobenzene

[0032] Take 0.012 mmol of ferroceneimine cyclopalladium-phosphine adduct, 0.72 mmol of cyclopropylboronic acid, and 1.5 mmol of NaOH into a 10 ml Schlenk tube, and repeatedly vacuumize and fill with N 2 5 times. N 2 Add 0.6 mmol 3-bromonitrobenzene and 2 ml toluene under protection. Stir at room temperature for 5 min, then place in an oil bath heated to 100 °C, and react for 3 h. Stop the reaction and cool to room temperature. The reaction solution was diluted with ethyl acetate, filtered, washed once with water, and the organic phase was washed with Na 2 SO 4 Dry, filter and concentrate. The residue was separated by thin-layer chromatography using ethyl acetate / petroleum ether=1 / 20 as a developing solvent to obtain 78 mg of the target product with a yield of 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com