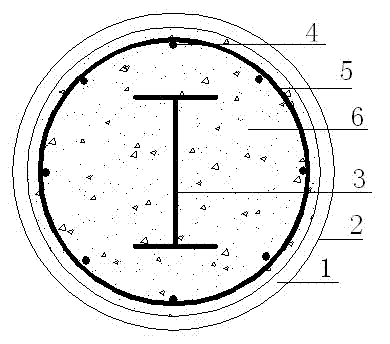

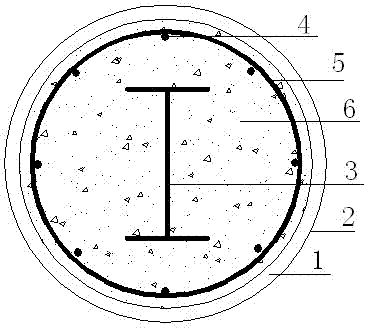

Preparation method of PVC-FRP pipe steel-reinforced concrete composite column

A PVC-FRP, PVC pipe technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of large influence of electromagnetic waves, heavy structure, unstable performance and durability, etc., to achieve broad application prospects and development space, structure Good overall performance, good ductility and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] (1) According to the requirements of the bearing capacity, select a PVC pipe 1 with a suitable cross-sectional size (the internal pressure of the PVC pipe is above 1Mpa), clean the surface of the PVC pipe 1, remove dust and debris on the surface, and fully dry the surface.

[0021] (2) Put the binder and curing agent in a certain proportion and accurately weigh them into the container, and stir them evenly with a stirrer to form epoxy resin (binder: curing agent = 3:1). Use a roller to evenly brush it on the surface of the PVC pipe, and then proceed to the construction of the next process.

[0022] (3) Fully soak the FRP material with epoxy resin, wind the FRP cloth 2 according to the FRP hoop spacing and strip width designed according to the bearing capacity, and squeeze it continuously during the winding process to ensure the tight combination between the FRP cloth 2 and the PVC pipe 1 , air bubbles are not allowed during the winding process; the entire winding proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com