Technology of spraying electrodes while depositing film in manufacture of flexible film photovoltaic battery

A photovoltaic cell and flexible thin film technology, applied in final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as increased electrode cleaning operations and folded equipment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

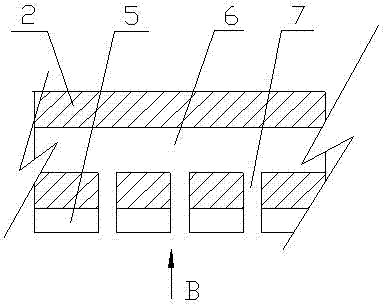

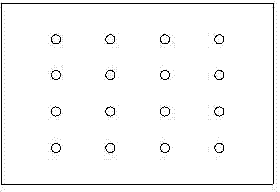

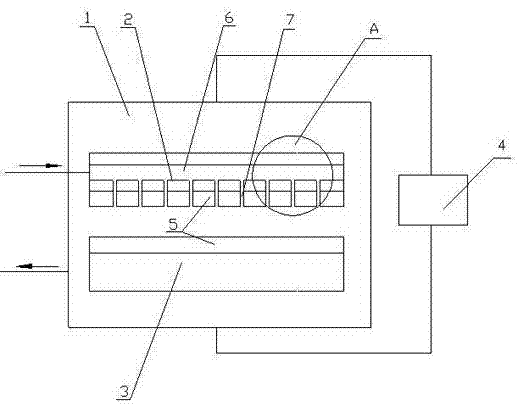

[0013] Examples such as figure 1 As shown, the equipment for performing PECVD operations in the manufacture of flexible thin-film photovoltaic cells includes vacuum equipment 1, which is equipped with a spray electrode 2 and a base electrode 3 corresponding to each other inside the vacuum equipment 1, and has a radio frequency power supply 4 outside the vacuum equipment 1 , the spray electrode 2 and the base electrode 3 are respectively connected to the radio frequency power supply 4, and the spray electrode 2 and the base electrode 3 are attached with a battery substrate 5; another example figure 2 with image 3 As shown, there is a gas channel 6 inside the spray electrode 2, and there are small holes 7 on the spray electrode 2 and the attached battery substrate 5, and the aperture of the small holes 7 is 0.05 mm, arranged in a matrix; the spray electrode The small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com