Method for recovering rare earth elements from a solid mixture containing a halophosphate and a compound of one or more rare earth elements

A halophosphate, rare earth element technology, applied in the preparation/processing of rare earth metal compounds, rare earth metal compounds, rare earth metal oxides/hydroxides, etc., can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

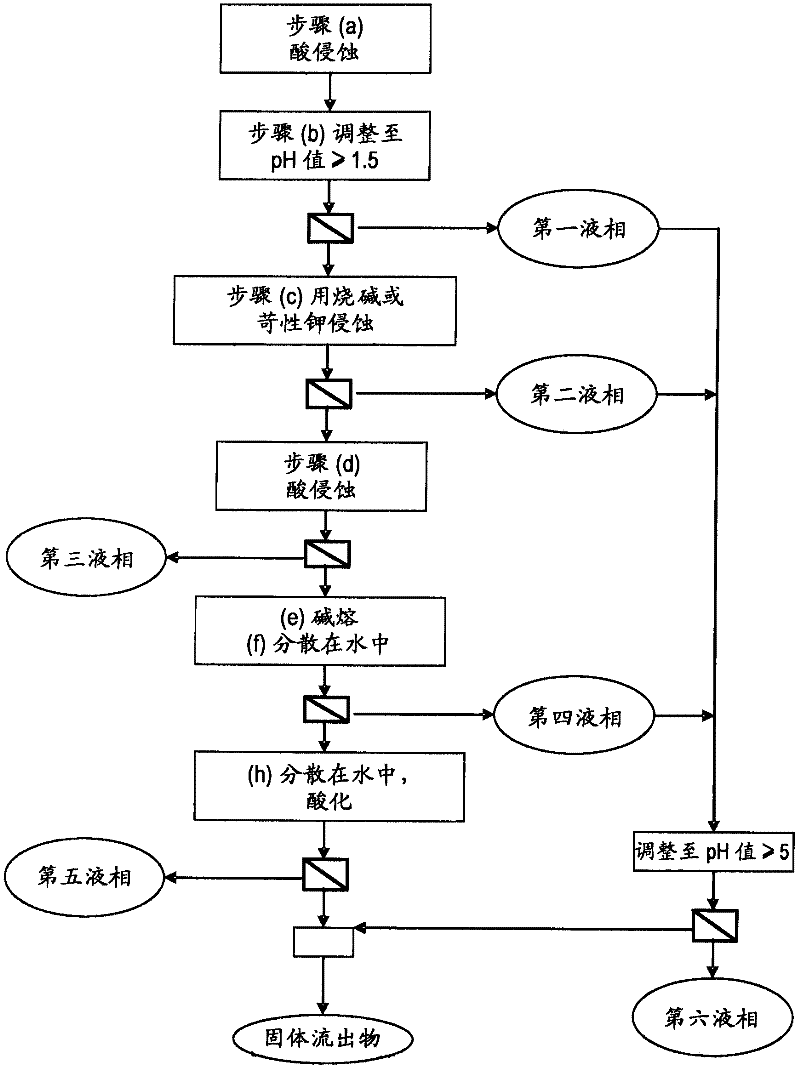

Image

Examples

Embodiment 1

[0101] This example relates to a method of the invention wherein nitric acid is used in the acid attack operation.

[0102] As a raw material mixture, luminescent body powder having the following composition expressed as oxides of various elements per 100 grams is used as a raw material:

[0103] Table 1

[0104] Eu 2 o 3

[0105] acid attack

[0106] In a stirred reactor, the phosphor powder was dispersed in water to obtain a dispersion heated to a temperature of 70° C. with a concentration of 170 g / l. The nitric acid solution was poured into the dispersion (which was stirred and heated) within 1 hour until the pH of the solution remained below 1. The mixture was then allowed to digest for 1 hour with stirring, keeping it at the same temperature and the same pH.

[0107] A solution of caustic soda having a concentration equal to 4N was then added to the mixture within 1 hour, so that the pH of the mixture rose to 2. The mixture was stirred for 1 hour.

[...

Embodiment 2

[0131] This example relates to the method according to the invention in which hydrochloric acid is used for the first acid attack of the phosphor powder. Subsequent steps of the method were performed in the same manner as in Example 1.

[0132] The table below shows the analysis of the filtered water recovered at the end of the first acid attack (Table 5) and at the end of the second acid attack (Table 6).

[0133] table 5

[0134] Al 2 o 3

[0135] Table 6

[0136] Eu 2 o 3

[0137] The total yield of rare earth elements was 84.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com