Polyacetal resin composition

A technology of polyacetal resin and composition, which is applied in the field of polyacetal resin composition, can solve the problem of insufficient polyacetal resin and pulp, thermal conductivity and molding processability of undisclosed polyacetal resin composition, and inappropriate Solve problems such as practicality, and achieve the effect of excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066]

[0067] The polyacetal resin composition of the present invention contains: the above-mentioned (a) 100 parts by weight of polyacetal resin, (b) 10 to 150 parts by weight of cellulose powder with an average particle diameter of 5 to 70 μm, (c) hindered phenol 0.01 to 3 parts by weight of antioxidants, (d) 0.01 to 3 parts by weight of at least one nitrogen-containing compound selected from aminotriazine compounds, guanamine compounds, hydrazide compounds and polyamides; it is also preferably prepared by further containing : (e) selected from alkali metals or alkaline earths kind 0.01 to 3 parts by weight of at least one metal compound of metal oxides, hydroxides, inorganic acid salts and carboxylates, and / or (f) selected from long-chain fatty acids, derivatives of long-chain fatty acids, polyoxyethylene Prepared with 0.01-3 parts by weight of at least one processing aid of alkyl glycol and silicone compound.

[0068] In the present invention, the specific mode of the...

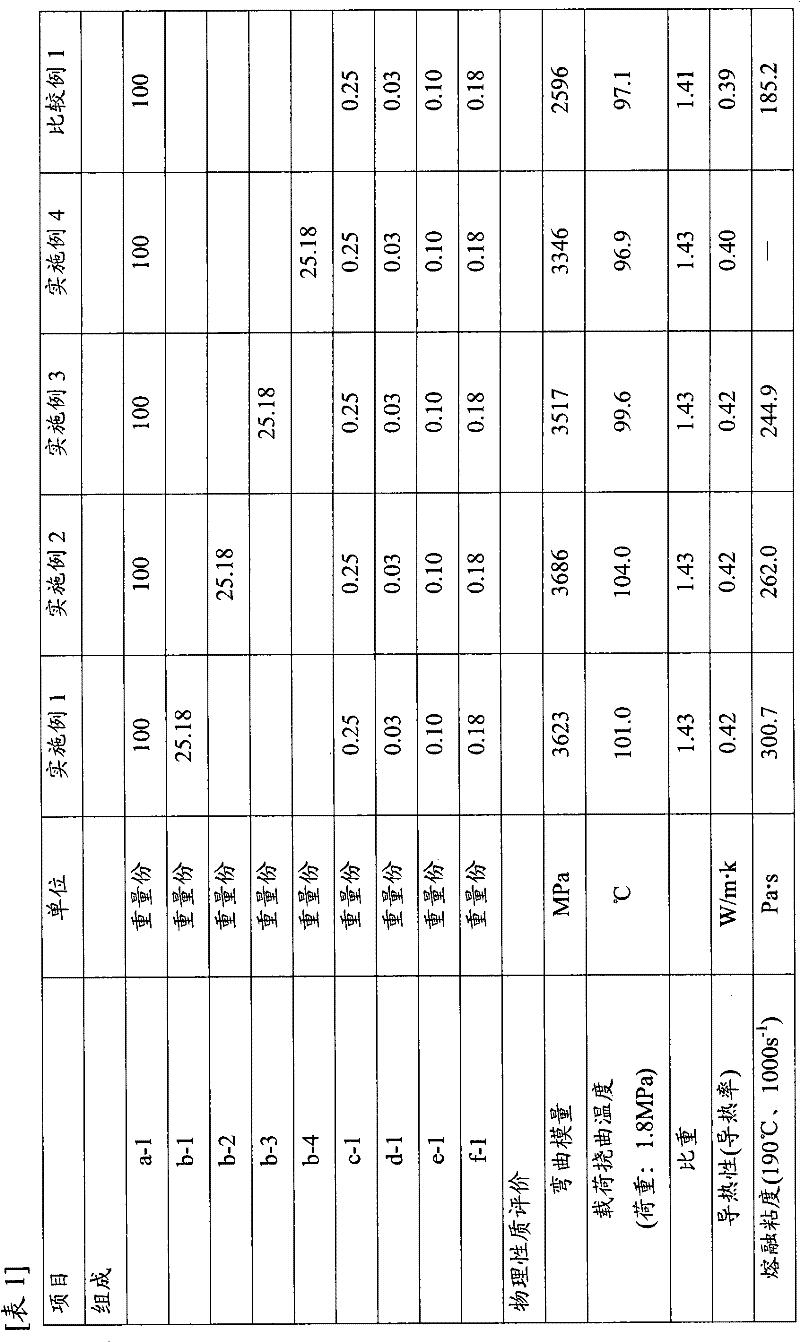

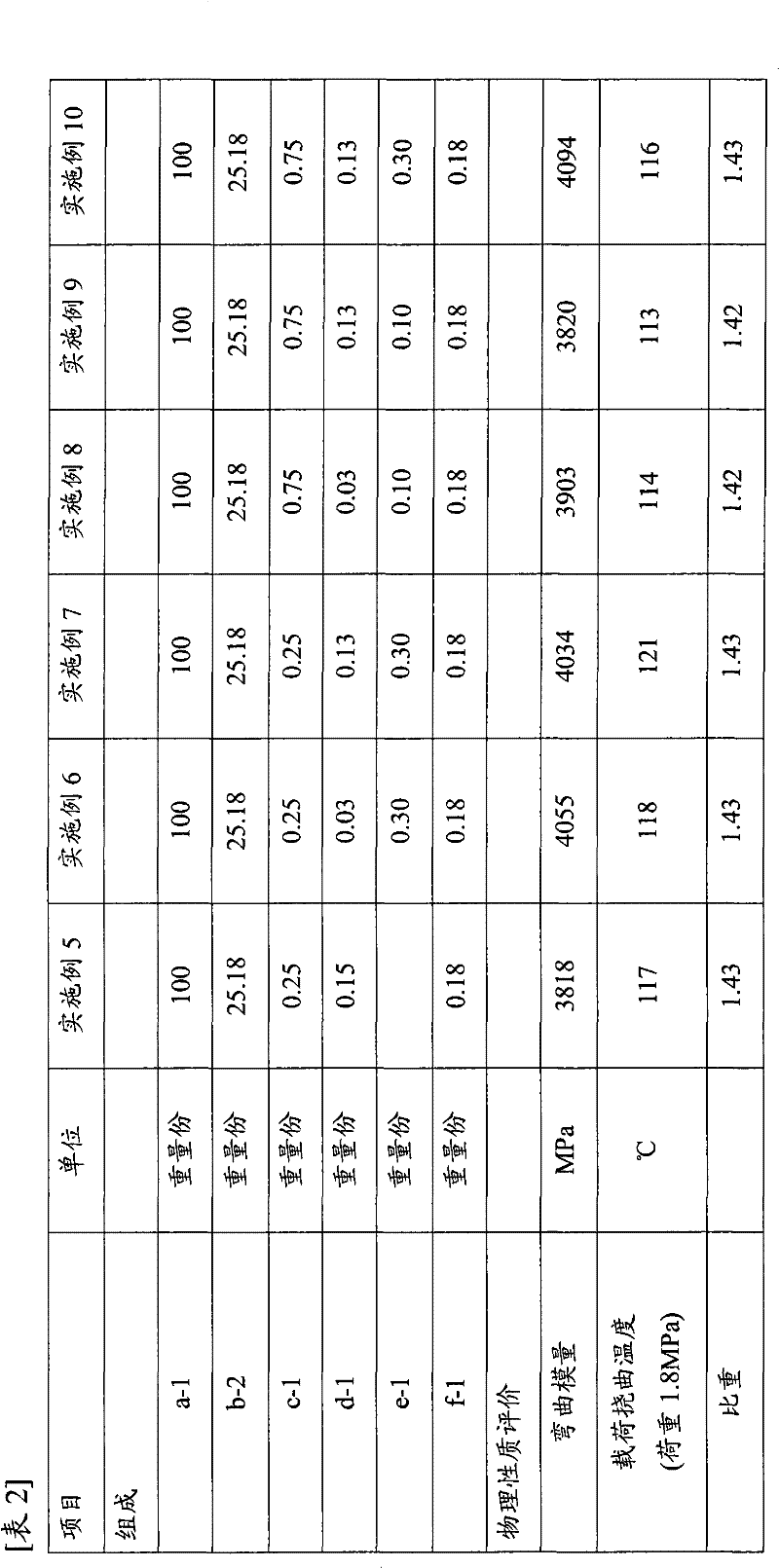

Embodiment 1~10、 comparative example 1

[0085](c) hindered phenolic antioxidant, (d) nitrogen-containing compound, (e) metal compound and (f) processing aid are melt-mixed in (a ) polyacetal resin, the mixture was mixed with (b) cellulose powder in the ratio shown in Table 1, and melted and kneaded with a twin-screw extruder to prepare a granular polyacetal resin composition. Using the obtained pellets, predetermined test pieces were molded by an injection molding machine, and test evaluation was performed. The results are shown in Table 1 and Table 2.

[0086] [use ingredient]

[0087] The details of the ingredients used are shown below.

[0088] (a) polyacetal resin

[0089] (a-1) Polyacetal resin, melt index = 27 g / 10 minutes (manufactured by Polyplastics Co., Ltd. (Polyplastics Co., Ltd.))

[0090] (b) Cellulose powder

[0091] (b-1) KC Flock W-50GK, average particle diameter: about 45 μm (manufactured by Nippon Paper Chemicals Co., Ltd.)

[0092] (b-2) KC Flock W-200, average particle diameter: about 32 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com