Method for prolonging service life of checkered roller

A patterned roll, life-span technology, applied in the direction of rolling force/roll gap control, rolling mill control device, metal rolling, etc., can solve the problem of increasing spare parts reserves and maintenance and replacement costs, affecting equipment operation rate, smooth production, and improving operation. Personnel labor intensity and other issues, to achieve the effect of reducing the cost of spare parts reserves and maintenance and replacement, optimizing planning, and balancing rolling pressure and load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the present invention will be further described in conjunction with examples.

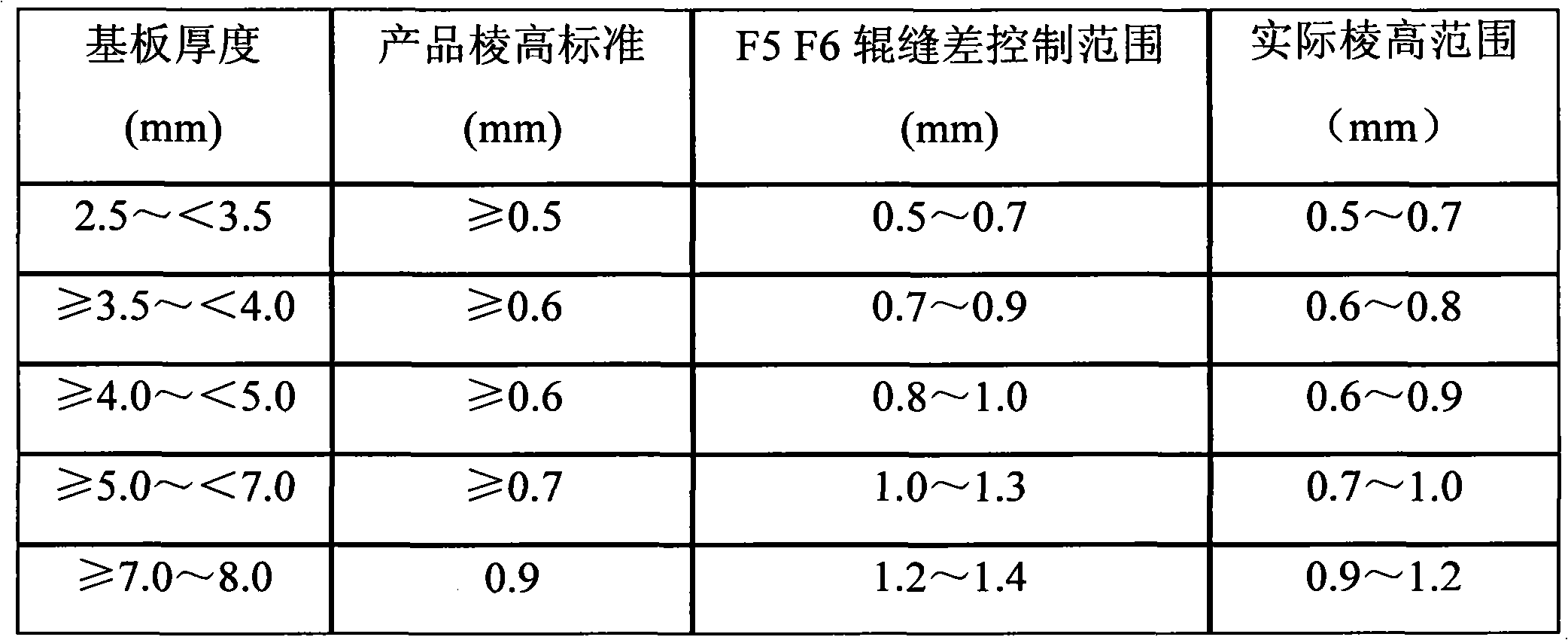

[0020] The basic conditions are: hot-rolled pattern plate, the maximum finished product size is 8.0mm, 6 finishing mills are used, the last finishing mill F6 (finished product stand) uses patterned rolls, and the bean depth of new rolls is 3.2mm.

[0021] The method for prolonging the service life of patterned rolls in the present invention mainly reduces the Due to the adverse effects of the production process and product varieties on the life of the patterned roller, the purpose of improving the service life of the patterned roller is achieved.

[0022] The specific method is:

[0023] 1. Reduce the temperature drop at the edge of checkered plate:

[0024] Under the condition that the temperature of the steel strip out of the furnace and the rolling start temperature remain unchanged, the temperature drop of the strip steel during the rolling process can be reduced by controlling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com