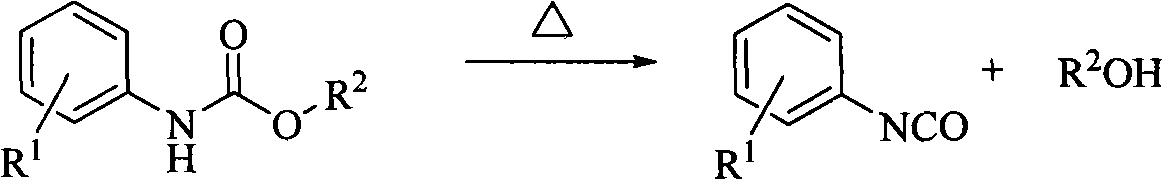

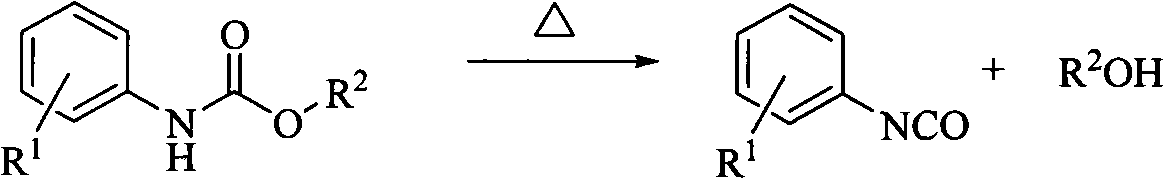

Method for preparing (substituted) aromatic monoisocyanate from (substituted) aryl carbamate through thermal decomposition

A technology of aryl monoisocyanate and aryl carbamate, applied in carbamate preparation, organic chemistry, etc., can solve the problems of by-products, achieve mild reaction conditions, high conversion rate of raw materials, and high energy utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 20.0 g of methyl phenylcarbamate was added into a 50 ml flask, and 0.1 g of catalyst ZnO was added at the same time, and the amount added was 0.5% of the mass of methyl phenylcarbamate. Under the condition of vacuum degree of 450mmHg, the reaction temperature was raised to 200°C, the condensed water temperature was 20°C, and the reaction was carried out for 120min. After the reaction, the fraction was treated with di-n-butylamine and analyzed by HPLC. The phenylisocyanate in the fraction was 13.26g , the yield was 84.1%.

Embodiment 2

[0022] In a 50ml flask, add 20.0g of methyl phenylcarbamate, while adding 0.2g of catalyst Co 2 o 3 , the addition amount is 1% of the quality of methyl phenylcarbamate. Under the condition of vacuum degree of 480mmHg, the reaction temperature was raised to 200°C, the condensed water temperature was 20°C, and the reaction was carried out for 100min. After the reaction, the fraction was treated with di-n-butylamine and analyzed by HPLC. The phenylisocyanate in the fraction was 13.81g , the yield was 87.6%.

Embodiment 3

[0024] Add 25.0 g of ethyl phenylcarbamate to a 50 ml flask, and at the same time add 0.2 g of catalyst neutral Al 2 o 3 , the addition amount is 0.8% of the mass of ethyl phenylcarbamate. Under the condition of vacuum degree of 540mmHg, the reaction temperature was raised to 220°C, the condensed water temperature was 40°C, and the reaction was carried out for 120min. At the end of the reaction, the fraction was treated with di-n-butylamine and analyzed by HPLC. The phenylisocyanate in the fraction was 14.09g , and the yield was 76.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com