Electric stress relief adhesive for connecting thermal shrinkage cable accessory

A heat-shrinkable cable and electric stress technology, which is applied in the direction of cable accessories, cable installation, electrical components, etc., can solve the problems of cumbersome process, etc., and achieve the effects of high tensile strength, improved electrical stress distribution, and excellent bonding and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

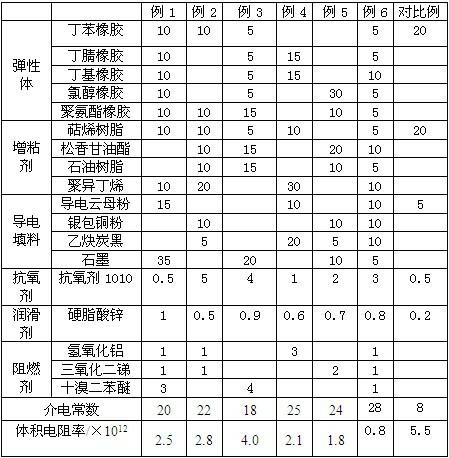

[0023] According to the corresponding components and the addition amount in Table 1, weigh each component. The electrical stress relieving glue for connecting heat-shrinkable cable accessories of the present invention can be obtained by mixing all the components uniformly in a kneader and then extruding them in a rubber extruder to form strips.

Embodiment 2-6

[0025] Weigh each component according to the corresponding components and the addition amount in Table 1. According to the method described in Example 1, the electrical stress relieving glue for connecting heat-shrinkable cable accessories of the present invention was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com