Method for preparing Cerasus humilis kernel extract

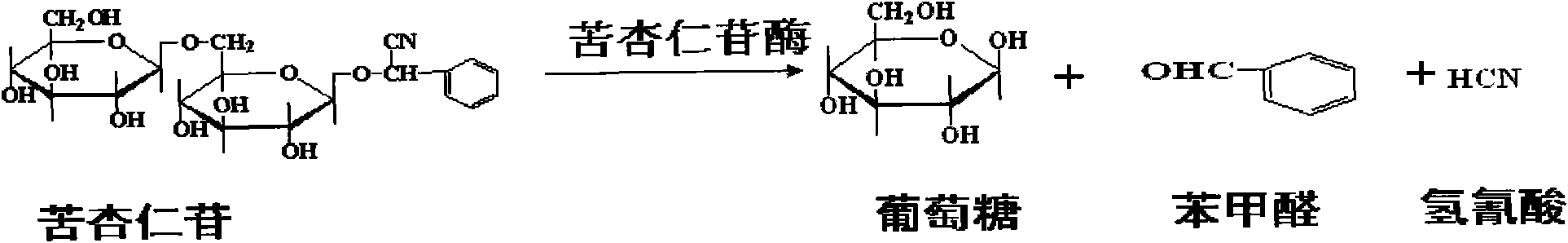

A technology of eucalyptus and extract, applied in the field of preparation of eucalyptus extract, can solve problems such as denaturation of eucalyptus protein, affecting the in-depth development and utilization of eucalyptus protein, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Drying 100 g of Prunus oleifera by sun-drying so that the water activity of the Prunus oleifera is 0.70 to obtain dried Prunus prune;

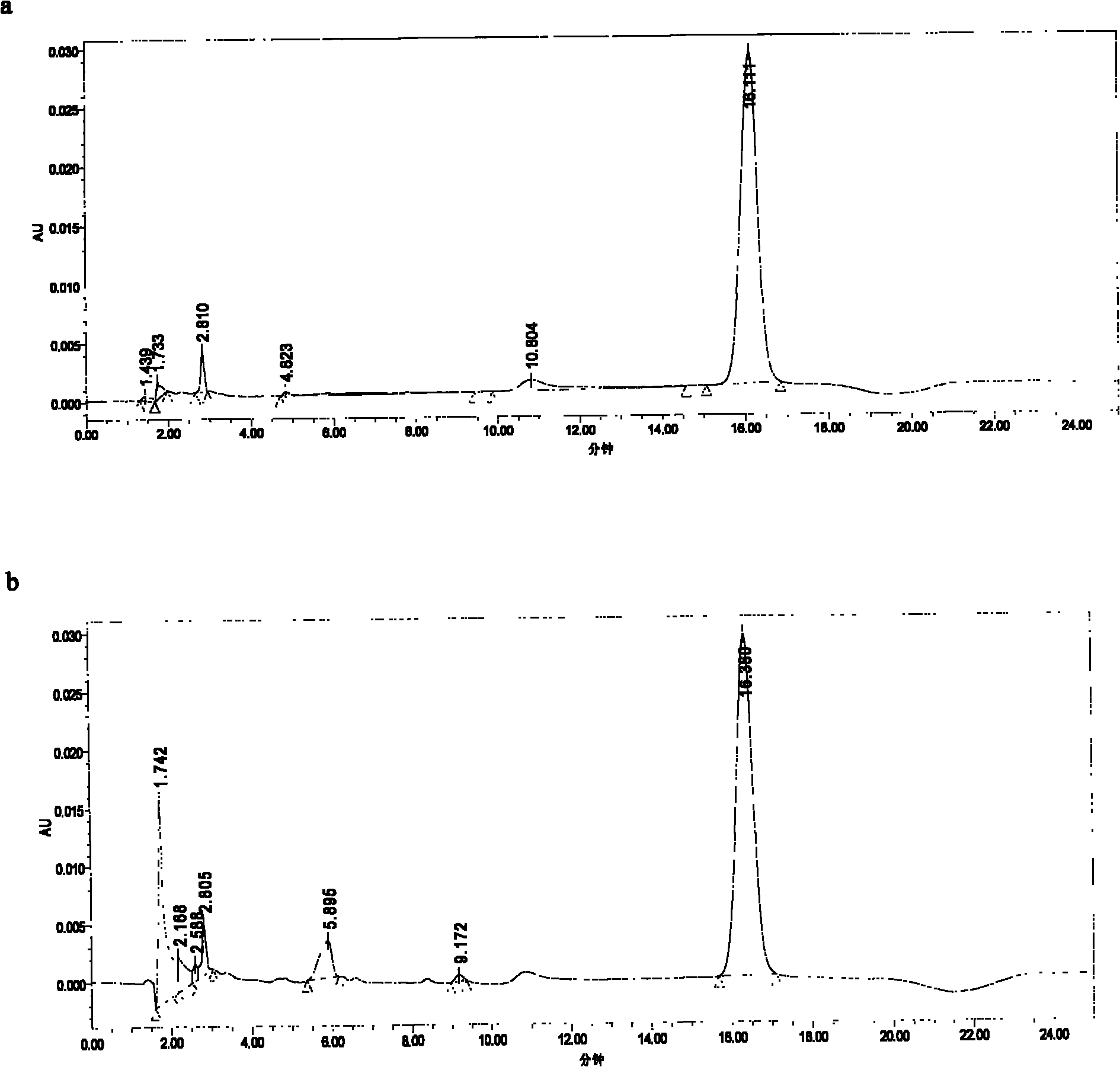

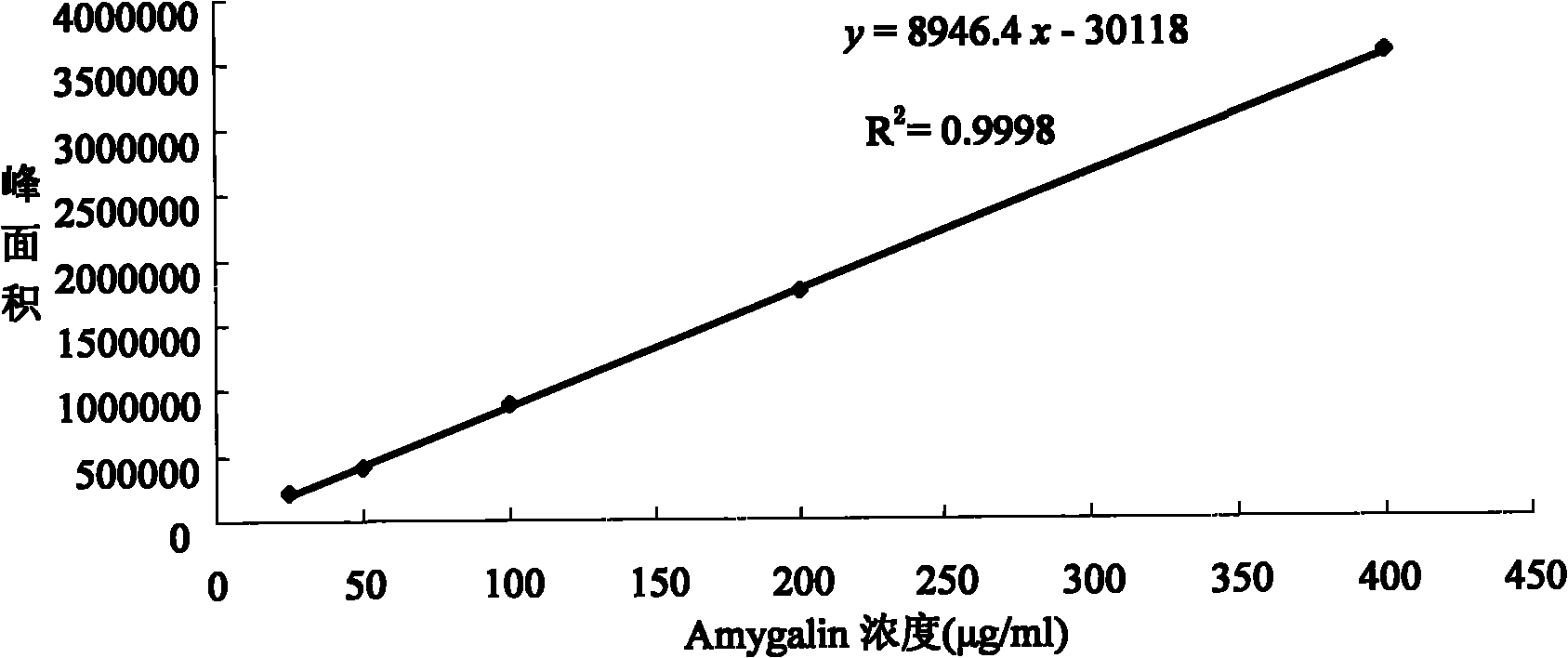

[0029] According to the Soxhlet extraction method, the Prunus oleifera oil as raw material is determined, the amygdalin in Prunus punctifera as a raw material is determined by high performance liquid chromatography, and the amygdalin in Prunus punctifera as a raw material is determined according to the Kjeldahl method. As can be seen, the mass percentages of oil, amygdalin and protein are respectively 39.8%, 3.45% and 28.6%;

[0030] 2) Under the condition of keeping the water activity of the dried Echinacea obtained in step 1) at 0.70, crush the dried Euliscus to a size of 10 mesh to obtain 97.1 g of crushed Eulison;

[0031] 3) Under the condition that the water activity of the pulverized Prunus obtained in step 2) was kept at 0.70, the Prunus oil in the pulverized Prunus was extracted with an organic solvent at 50° C. to obtain 38...

Embodiment 2

[0042] 1) Dehydrating 100 g of Prunus oleifera with 20 mL of ethanol as a dehydrating agent, so that the water activity of Prunus oleifera is 0.53 to obtain dried Prunus prune;

[0043] According to the Soxhlet extraction method, the Prunus oleifera oil as raw material is determined, the amygdalin in Prunus punctifera as a raw material is determined by high performance liquid chromatography, and the amygdalin in Prunus punctifera as a raw material is determined according to the Kjeldahl method. As can be seen, the mass percentages of oil, amygdalin and protein are respectively 39.8%, 3.45% and 28.6%;

[0044] 2) Under the condition that the water activity of the dried Euliscus obtained in step 1) was kept at 0.53, the dried Euliscus was crushed to 120 mesh to obtain 95.26 g of the crushed Euliscus;

[0045] 3) Under the condition that the water activity of the pulverized Eurydene obtained in step 2) is kept at 0.53, use supercritical CO at 42°C to 2 The method of fluid extrac...

Embodiment 3

[0056] 1) Dry 100 g of Prunus oleifera by freeze-drying method, so that the water activity of Prunus oleifera is 0.40, and obtain dried Prunus mellifera; The vacuum freeze-drying operation is carried out at a temperature of 20-40Pa, and the freeze-drying is completed when the temperature of the material is close to room temperature.

[0057]According to the Soxhlet extraction method, the Prunus oleifera oil as raw material is determined, the amygdalin in Prunus punctifera as a raw material is determined by high performance liquid chromatography, and the amygdalin in Prunus punctifera as a raw material is determined according to the Kjeldahl method. As can be seen, the mass percentages of oil, amygdalin and protein are respectively 39.8%, 3.45% and 28.6%;

[0058] 2) Under the condition of keeping the water activity of the dried Euliscus obtained in step 1) at 0.40, crush the dried Euliscus to 60 meshes to obtain 94.68 g of the crushed Euliscus;

[0059] 3) Under the condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com