Method for preparing light scattering film

A light scattering and thin film technology, which is applied in the coating process and coating of metal materials, can solve the problems of difficult dispersion, poor dispersion performance of dispersed phase particles, and decreased light transmittance of matrix materials, so as to achieve simple and easy-to-take materials , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a method for preparing a light scattering film of the present invention, which comprises the following steps:

[0024] (1) Dissolve the inorganic nano-powder in an organic solvent, use the physical dispersion method to prepare a stable and uniform organic phase sol, or replace the water phase sol with an organic solvent to form a stable and uniform organic phase sol as a spray coating liquid;

[0025] (2) A growth chamber is provided, and a vacuum system capable of making the growth chamber in a vacuum state is arranged in the growth chamber;

[0026] (3) A deposition substrate for fixing the base material to be sprayed with the light scattering film is arranged in the growth chamber, and the deposition substrate and the base material are in a heated state;

[0027] (4) Use the spray system to spray the spraying liquid toward the deposition substrate into the growth chamber. Due to the action of the vacuum system, the growth chamber is in a vacuum state, ...

Embodiment 2

[0037] Example 2, the method for preparing the light scattering film in this example is basically the same as that in Example 1, the difference is: in this example, methanol phase nano-zinc oxide sol with a concentration of 0.8% is used as the spraying liquid, and quartz glass is used as the spray solution. As the base material, the spray system is used to spray the spraying liquid into the growth chamber. The growth chamber uses a vacuum system to make the zinc oxide sol sprayed into it rapidly expand in volume and become mist, and has an initial velocity to fly to the deposition substrate; During the process, the solvent rapidly volatilizes, is pumped away by a high-speed vacuum pump, and is captured and recovered by a cold trap, while the solute forms a light-scattering film on the quartz glass substrate fixed on the heated deposition substrate. The light transmittance of the film was 89.1%, and the haze was 69.0%.

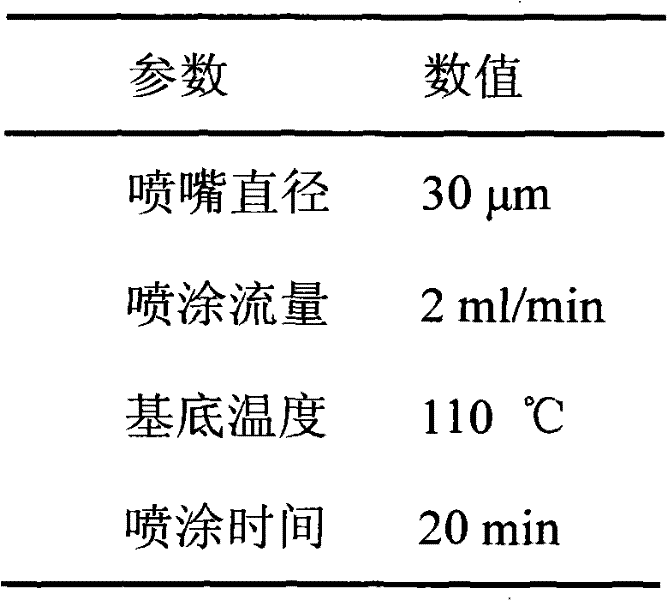

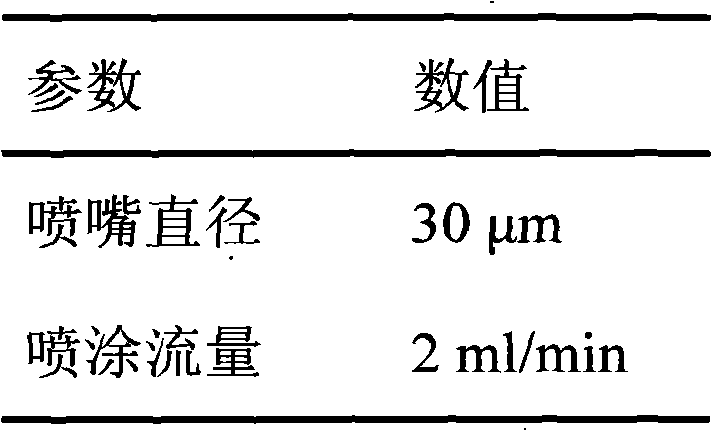

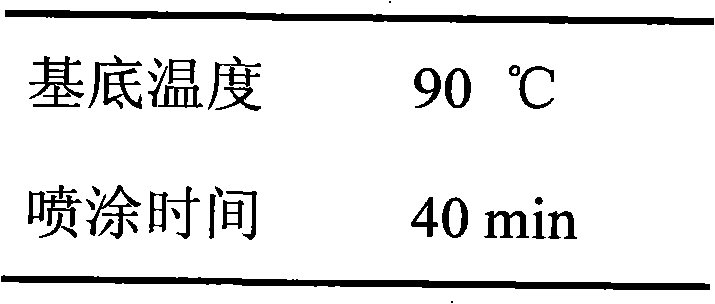

[0038] The spraying parameters are shown in Table 1:

[...

Embodiment 3

[0041]Example 3, the method for preparing the light scattering film in this example is basically the same as that in Examples 1 and 2, the difference is that: this example uses methanol phase nano-zinc oxide sol with a concentration of 0.3% and a nano-zinc oxide sol with a concentration of 0.3%. The methanol phase nano-silica mixed sol is used as the spray liquid, and ITO is used as the base material. The spray system is used to spray the spray liquid into the growth chamber. The growth chamber uses a vacuum system to make the instantaneous volume of the zinc oxide / silica sol sprayed into it. It expands rapidly to become fog, and has an initial speed of flying to the deposition substrate; during the flight, the solvent volatilizes rapidly, is pumped away by a vacuum pump with a large pumping speed, and is captured and recovered by a cold trap, while the solute is fixed on the heated deposition substrate. A light-scattering film was formed on the ITO substrate. The light transm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com