Lubricating structure of timing chain system of engine

A lubricating structure and engine technology, which is applied in the direction of engine lubrication, engine components, valve accessories, etc., can solve the problems of no lubrication, increased friction of chains, sprockets and guide rails, etc., and achieve the effect of reducing running time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

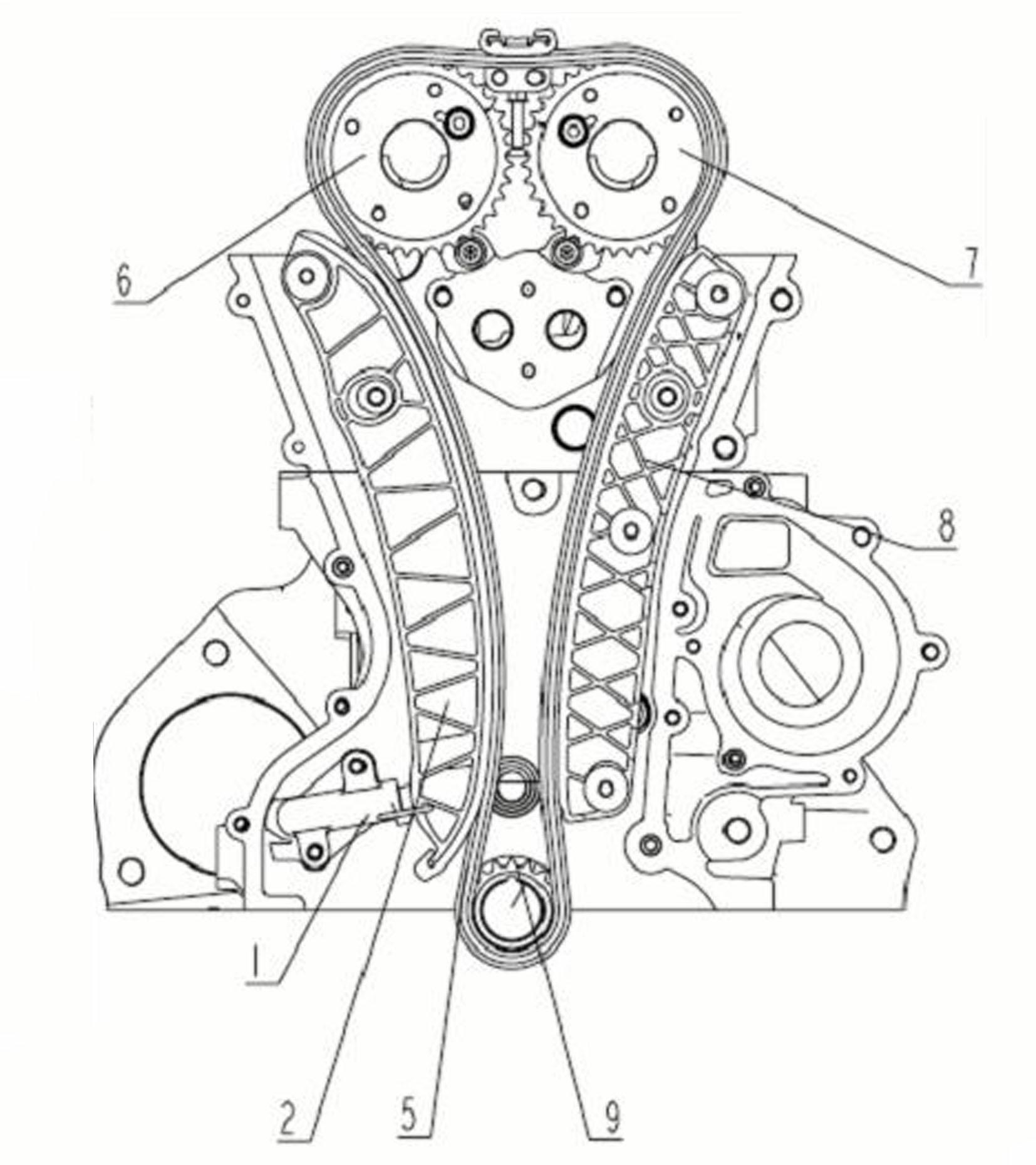

[0017] Such as figure 1 As shown, the lubrication mechanism of the timing chain system mainly involves the hydraulic tensioner 1, the timing chain moving rail assembly 2 and the timing chain assembly 5. The entire timing chain system is mounted on the front of the engine. The moving rail assembly 2 is installed on the cylinder head 10 , and the hydraulic tensioner 1 is installed on the cylinder body 20 . The oil from the oil channel is guided by the oil groove 11 on the tensioner to introduce the oil into the oil inlet 12 of the tensioner, forming oil pressure, pushing the piston 13 to move, and driving the moving rail assembly 2 to tighten the timing chain 5 .

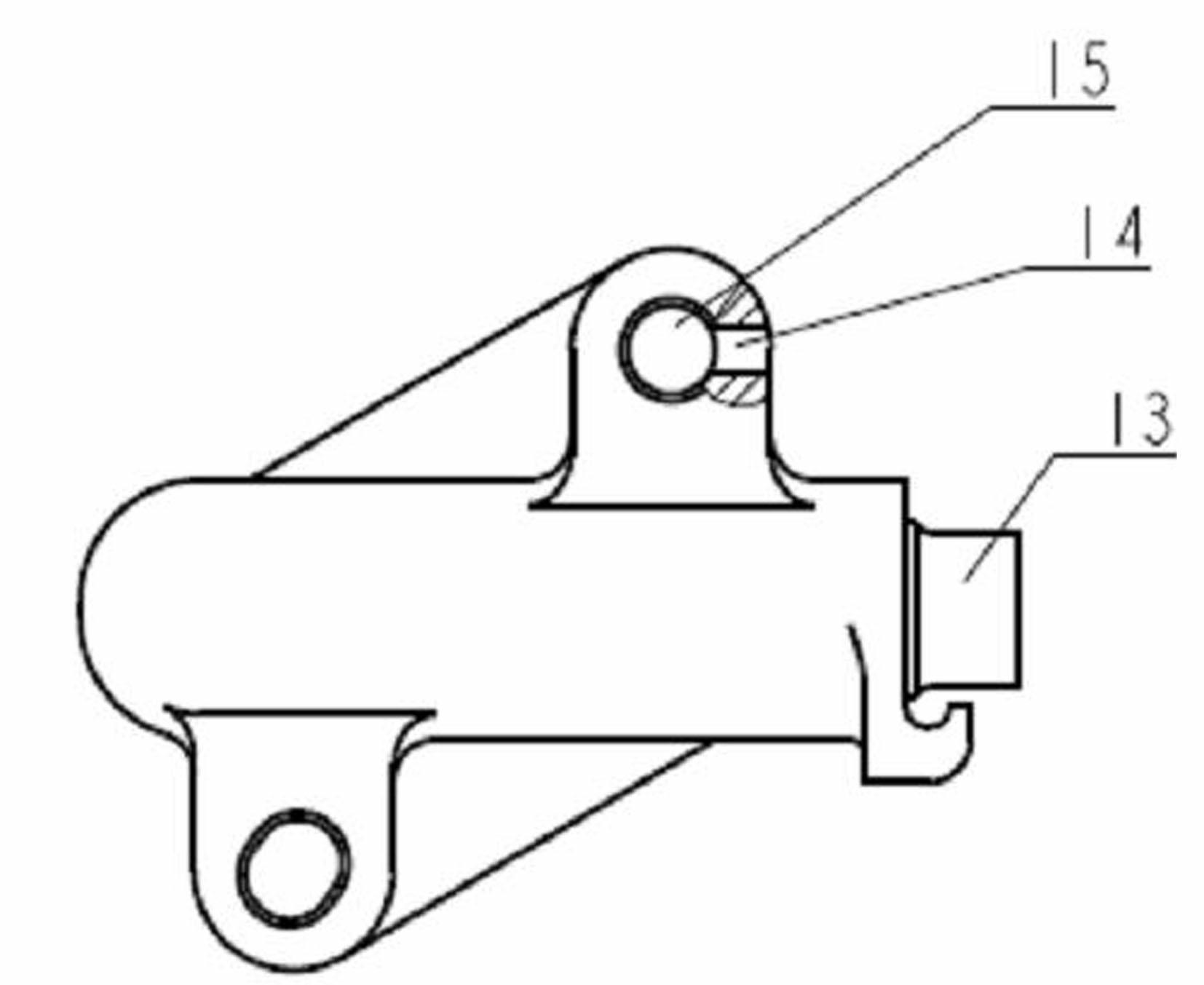

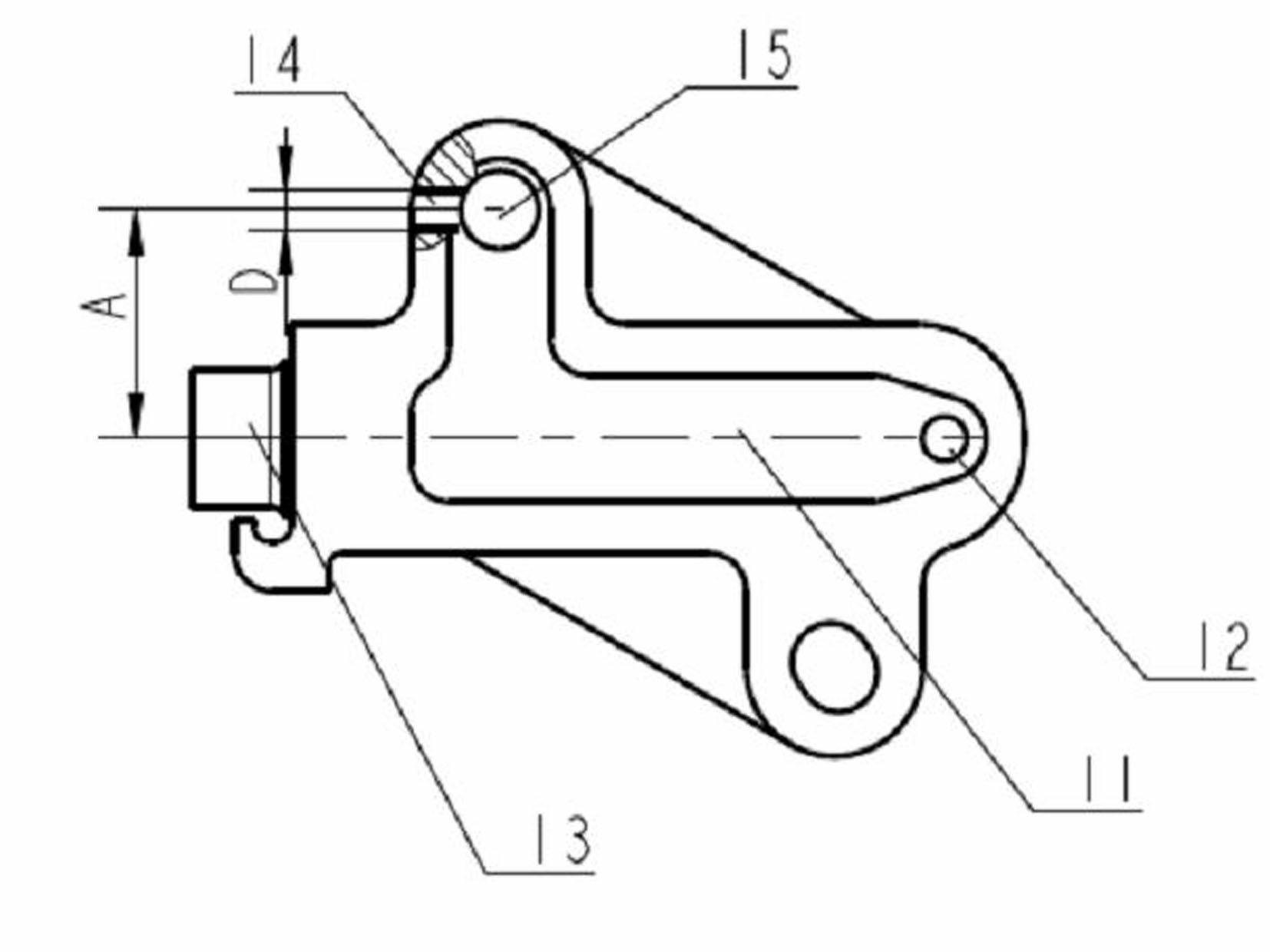

[0018] By calculating the relationship between the oil pressure and the spatial position, an oil injection hole 14 with a smaller diameter is opened on the bolt mounting bracket on the upper part of the tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com