Multi-frequency division pulse width modulation control circuit for high-power laser power supply

A technology of pulse width modulation and laser power supply, which is applied in the direction of output power conversion devices and electrical components, can solve the problems that restrict the increase of output power of high-power laser discharge power supply, the decrease of conversion efficiency and stability, and the high inductance and inductance. Improve the total operating switching frequency, reduce the size of the power supply, and reduce the effect of operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

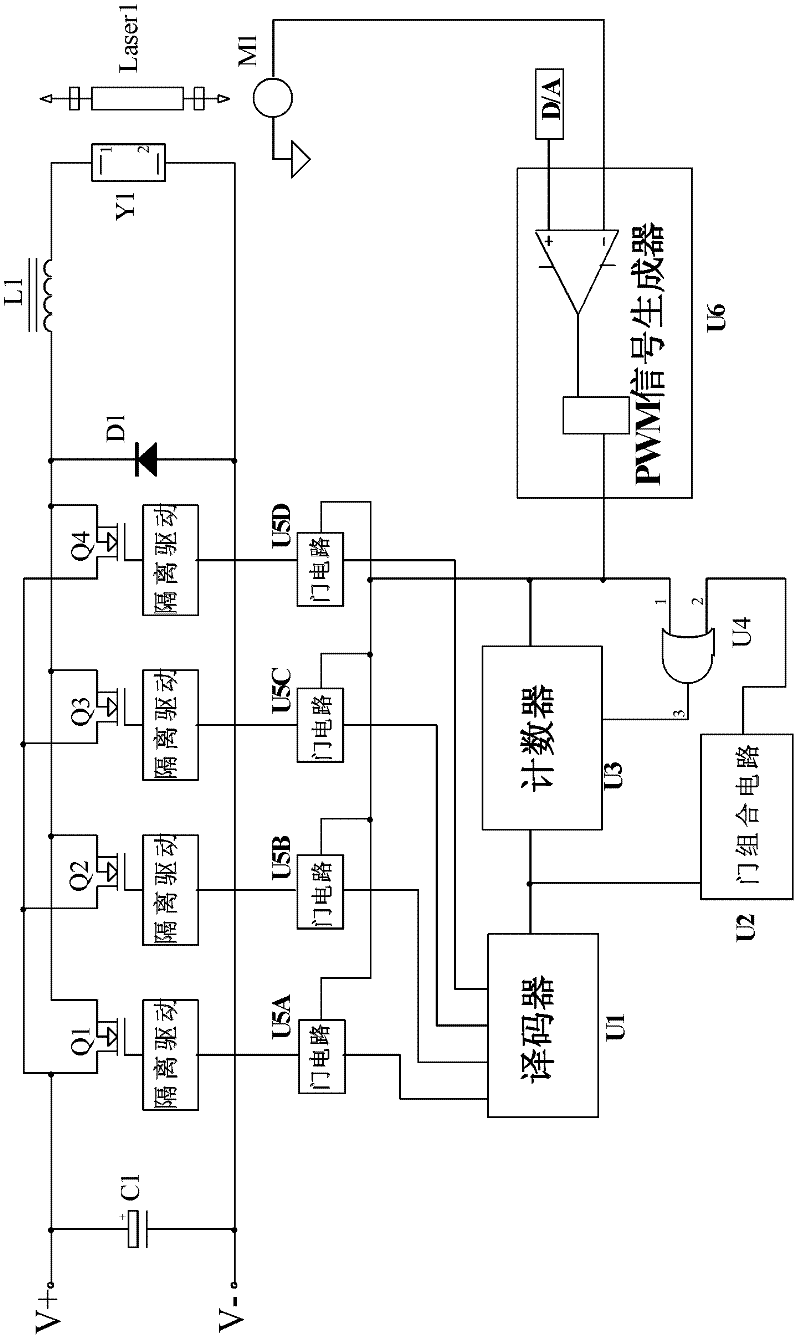

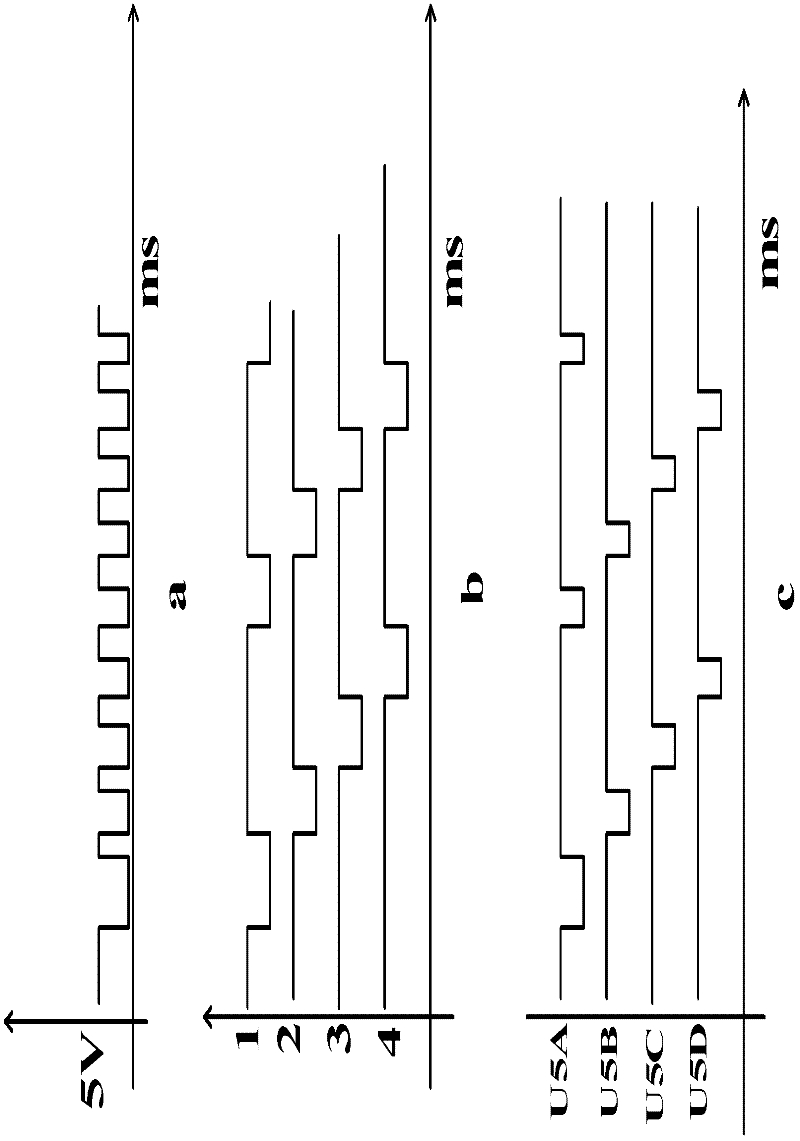

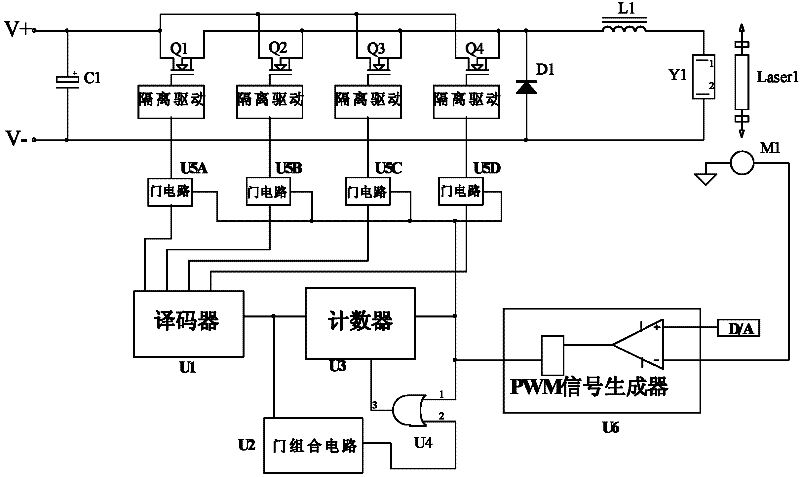

[0024] a kind of like figure 1 , 2 The shown high-power yttrium aluminum garnet crystal YAG laser power supply uses a four-frequency pulse width modulation control circuit, including a PWM signal generator U6 using a model TL494 chip. The PWM signal generator U6 is used to control a group of parallel-connected power switch tubes Q1, power switch tube Q2, power switch tube Q3, and power switch tube Q4 to provide power for high-power YAG laser discharge. The power switch tube Q1, the power switch tube Q2, the power switch tube Q3, and the power switch tube Q4 use IGBTs of the type MDI550-12A4.

[0025] There is a four-digit frequency division circuit composed of a cascaded four-bit binary counter U3 of model 74HC93 and a three-eight line decoder U1 of model 74HC138. The input end of the four-bit binary counter U3 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com