Novel electromagnetic heated food processing device

A food processing device and electromagnetic technology, applied in food processing, food preparation, food science, etc., can solve the problems of affecting processing efficiency, high labor intensity, and low quality of finished products, so as to ensure processing quality, convenient operation, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

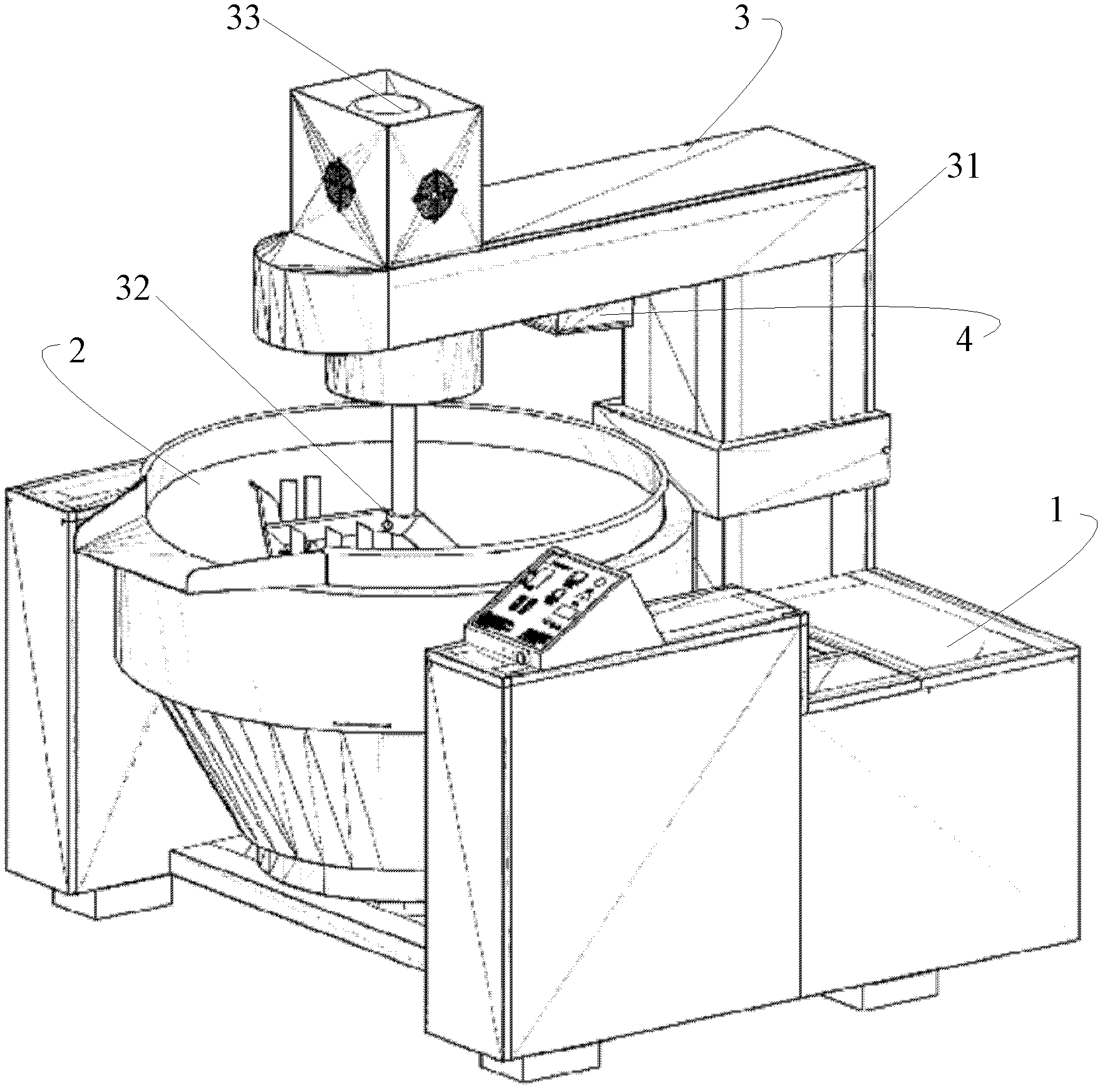

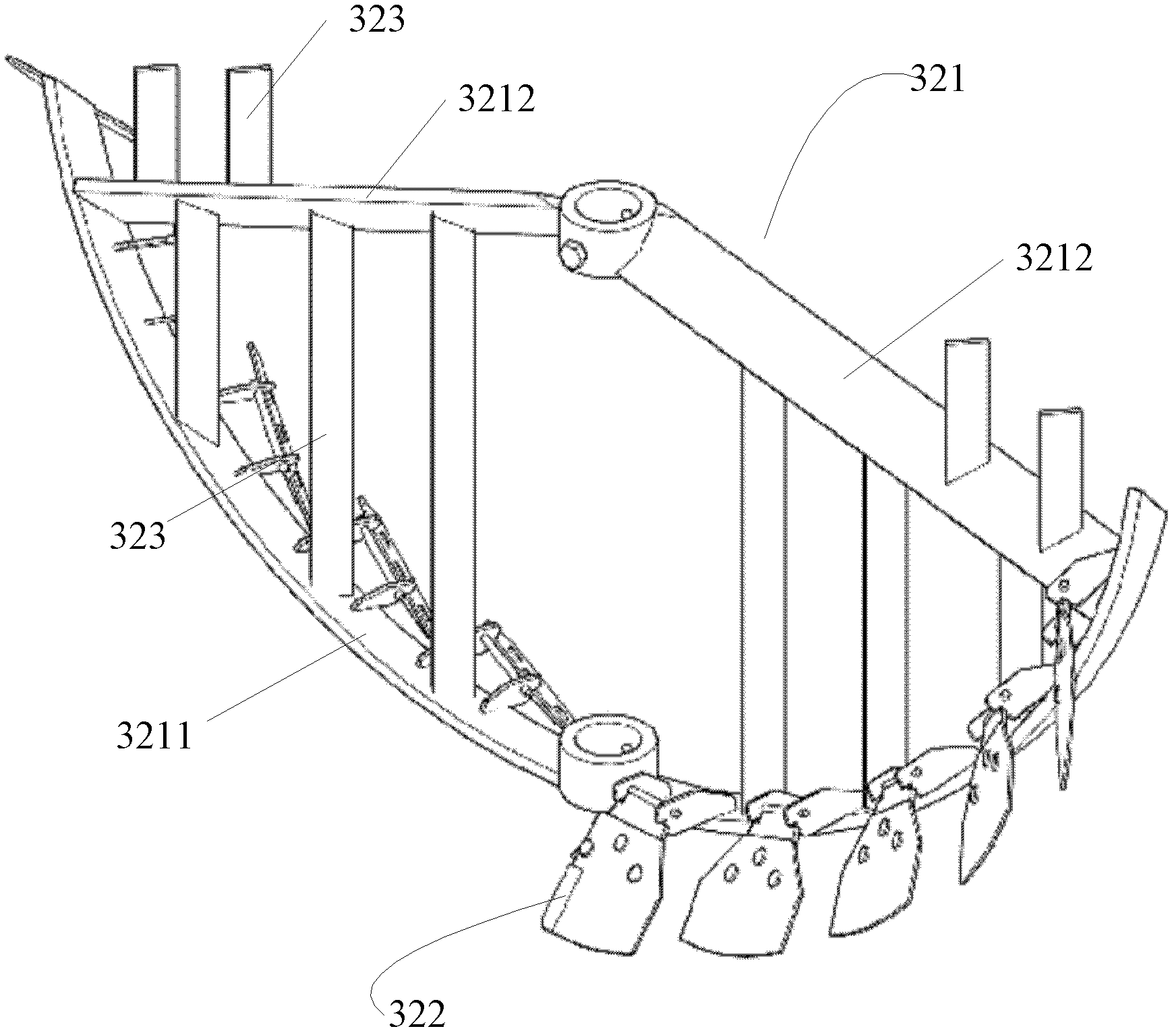

[0025] Such as figure 1 , 2 As shown, the novel electromagnetic heating food processing device of the present invention includes a base 1, a pot body 2, a stirring part 3 and an electric control system. It is made by forging to ensure that the heavy metal content released by the pot body 2 during the electromagnetic heating process is within the safety standard range.

[0026] The above-mentioned pot body 2 includes an integrally formed inner wall of the pot and an outer wall of the pot. A hollow interlayer structure is formed between the inner wall of the pot and the outer wall of the pot. The outer side of the inner wall of the pot is wound with an electromagnetic coil for heating the inner wall of the pot and is provided with a detection device. A temperature probe for the inner wall temperature of the pot. Further, the outer wall of the pot is rotationally connected to the base 1 through a rotating structure, and the rotating structure is electrically connected to the el...

Embodiment 2

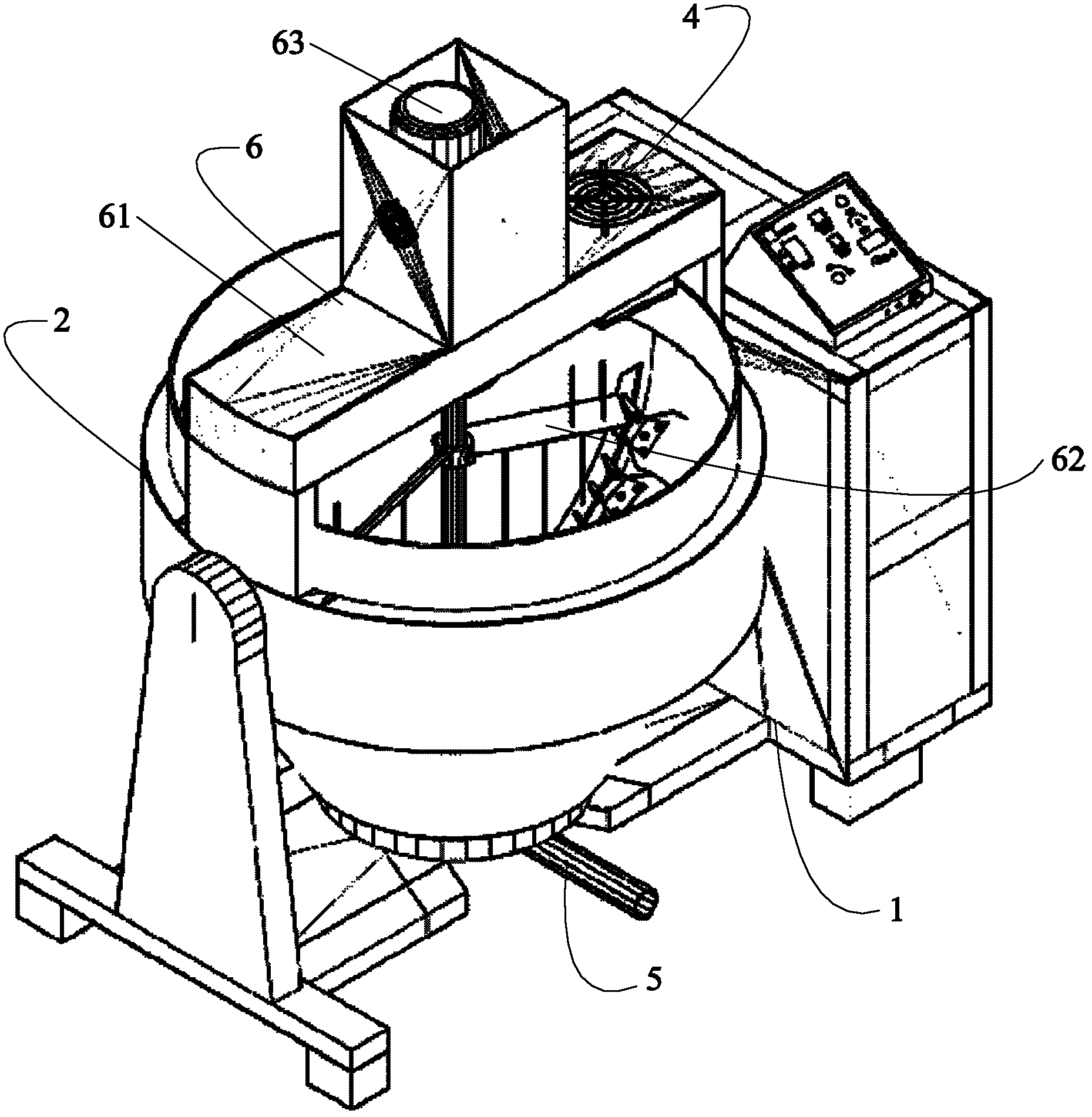

[0031] Such as figure 2 As shown, the embodiment described in this embodiment is basically the same as that of Embodiment 1, the only difference is that the outer wall of the pot in this embodiment is connected to the base 1 through a connecting rod, the connecting rod is an internal hollow structure, and the electromagnetic coil passes through The inner hollow structure of the connecting rod is electrically connected with the current generator arranged inside the base, and the current generator is then electrically connected with the electric control system. Preferably, the bottom of the inner wall of the pot is provided with a pipeline 5 which is opened and closed by a valve, which can facilitate the cooking of food and save labor and time.

[0032] Further, the stirring component 6 includes a support frame 61 and a stirring assembly; wherein, the support frame 61 is fixedly arranged on the upper part of the pot body 2, and the stirring assembly is installed on the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com