Electrochemical dissolving method for iridium powder

An electrochemical and electrolytic cell technology, applied in chemical instruments and methods, inorganic chemistry, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, etc., can solve the problem of low purity of iridium-containing compounds, increased preparation steps, and increased iridium Loss and other problems, to avoid impurity interference, high product purity, low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In the preparation step of the present invention, except for the impurities contained in the hydrochloric acid solution and the iridium powder two raw materials, no new impurity ions are added or generated. Therefore the present invention can be used for the preparation of high-purity chloroiridic acid aqueous solution, but this method does not limit this method to be used for low-purity iridium powder and hydrochloric acid dissolving to prepare low-purity chloroiridic acid aqueous solution. For example, the method of preparing low-purity chloroiridic acid aqueous solution by electrolysis of low-purity iridium powder and hydrochloric acid dissolution may be used in the recovery and purification process of iridium powder and iridium trichloride hydrate.

[0059] The present invention utilizes the principle of alternating current dissolution to directly dissolve iridium powder in hydrochloric acid to obtain an aqueous solution of chloroiridic acid, and the electrochemical ...

Embodiment 1

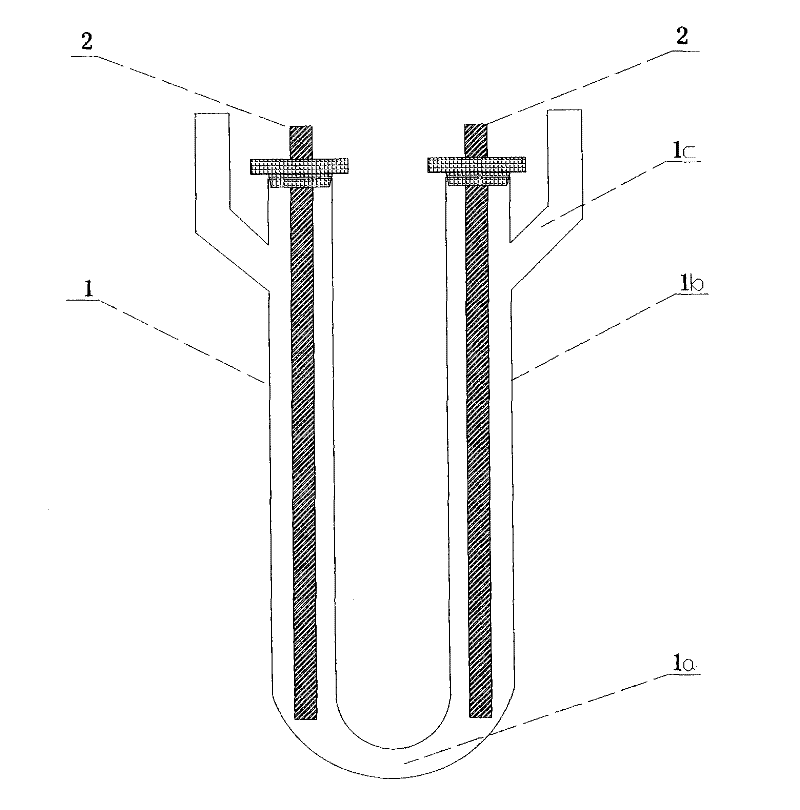

[0094] figure 1 is a schematic diagram of a U-shaped electrolytic cell. The diameter of U-shaped quartz electrolytic cell 1 is 50mm for the standpipe 1b, and the distance between the centers of the two standpipes is 180mm; the diameter of the bottom bend 1a is 18mm, and the diameter of the standpipe: the diameter of the bend=2.78; The length is 25mm; the volume of the electrolytic cell is 800ml. The electrode 2 uses Φ12mm and a length of 250mm for spectroscopically pure graphite electrodes. A cold water condenser is installed on both sides of the U-shaped quartz electrolytic cell 1 through the condenser interface 1c.

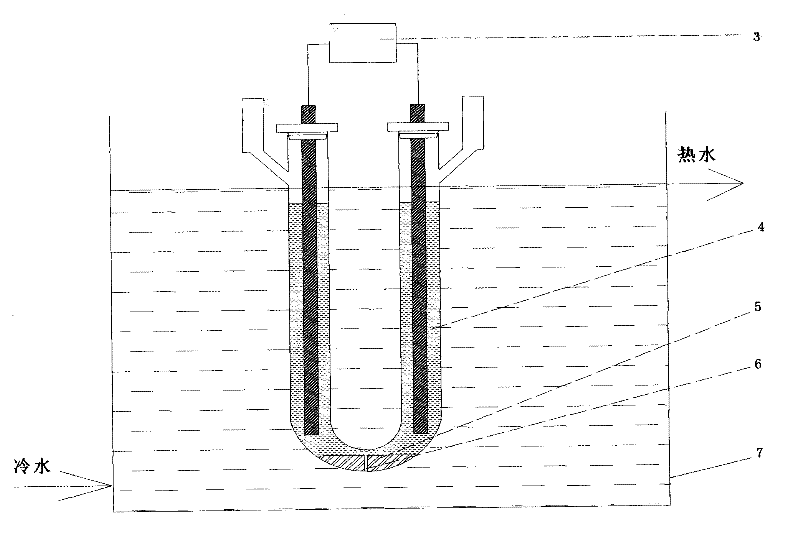

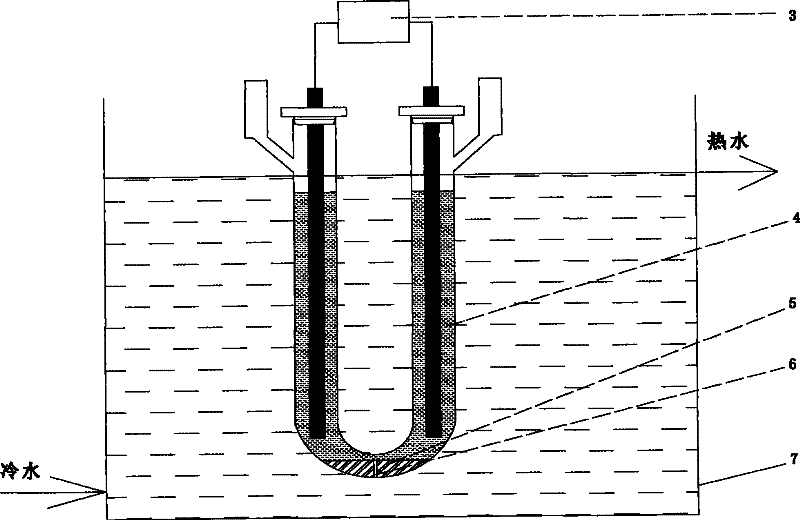

[0095] Iridium powder dissolving device see figure 2 , wherein: the two ends of the graphite electrode are connected to the AC arc generation controller 3, the iridium powder 5 is placed in the bottom elbow 1a of the U-shaped electrolytic cell, and the hydrochloric acid solution 4 is added to the electrolytic cell 1 and placed in the circulating cooling water...

Embodiment 2、3

[0098] Change the voltage of the electrolytic alternating current to 45 volts and 55 volts respectively, and the magnitude of the current varies from 10 to 40 amps. Other conditions are as shown in Example 1. The dissolution rates of iridium powder were 89% and 85% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com