A method for continuous electrochemical dissolution of iridium powder

An electrochemical and electrolytic cell technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of low purity of iridium compounds, increase the preparation steps, increase the loss of iridium, etc., achieve simplified operation, high product purity, ensure efficiency and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

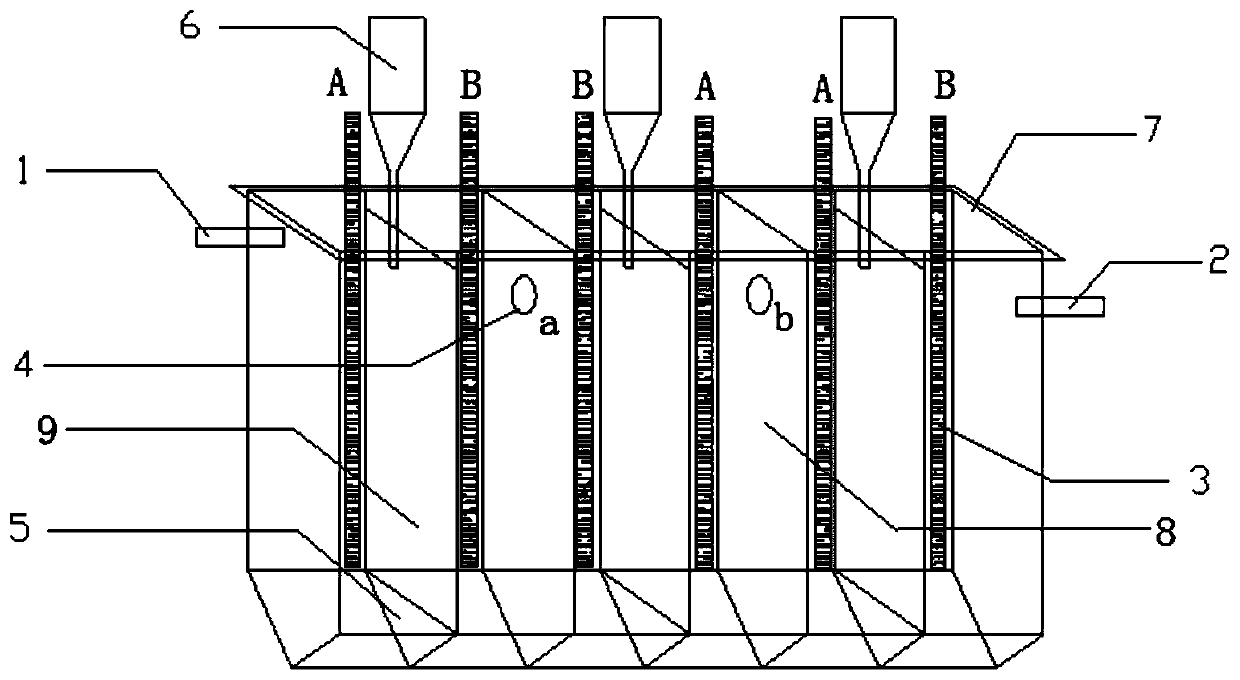

[0038] according to figure 1 The shown structure is provided with an electrolytic cell, and the electrolytic cell is made of quartz glass, and is divided into five tanks by the first dividing plate 8 ( figure 1 Only three tanks are shown in the figure, those skilled in the art can understand that according to figure 1Five tanks are set in the manner shown). The electrode chamber of the cell body of the electrolytic cell is 55mm long, 40mm wide and 300mm high. The first partition 8 and the second partition 9 are arranged in parallel, the second partition 9 has a gap of 20 mm from the top, and the bottom has a communicating channel 5 with a triangular cross-section. Each cell is divided into two electrode chambers by the second separator 9 . The overflow holes 4 (a, b) are opened on the top of the first partition 8, at a position 50 mm away from the top, and the hole diameter is 10 mm. A hydrochloric acid feed port 1 is arranged on the side wall of the first tank body, an...

Embodiment 2

[0043] Continuous electrochemically dissolving iridium powder in the same manner as in Example 1, the difference is that the electrode chamber of the electrolytic cell body is 60mm long, wide 35mm, and high 320mm; the cross section of the communicating channel 5 is a semicircle; , apply 30 volts of civilian alternating current at both ends of the A and B electrodes; Add iridium powder, now dissolve the product stream that has 21 grams per liter of concentration iridium to discharge from product outlet 2.

Embodiment 3

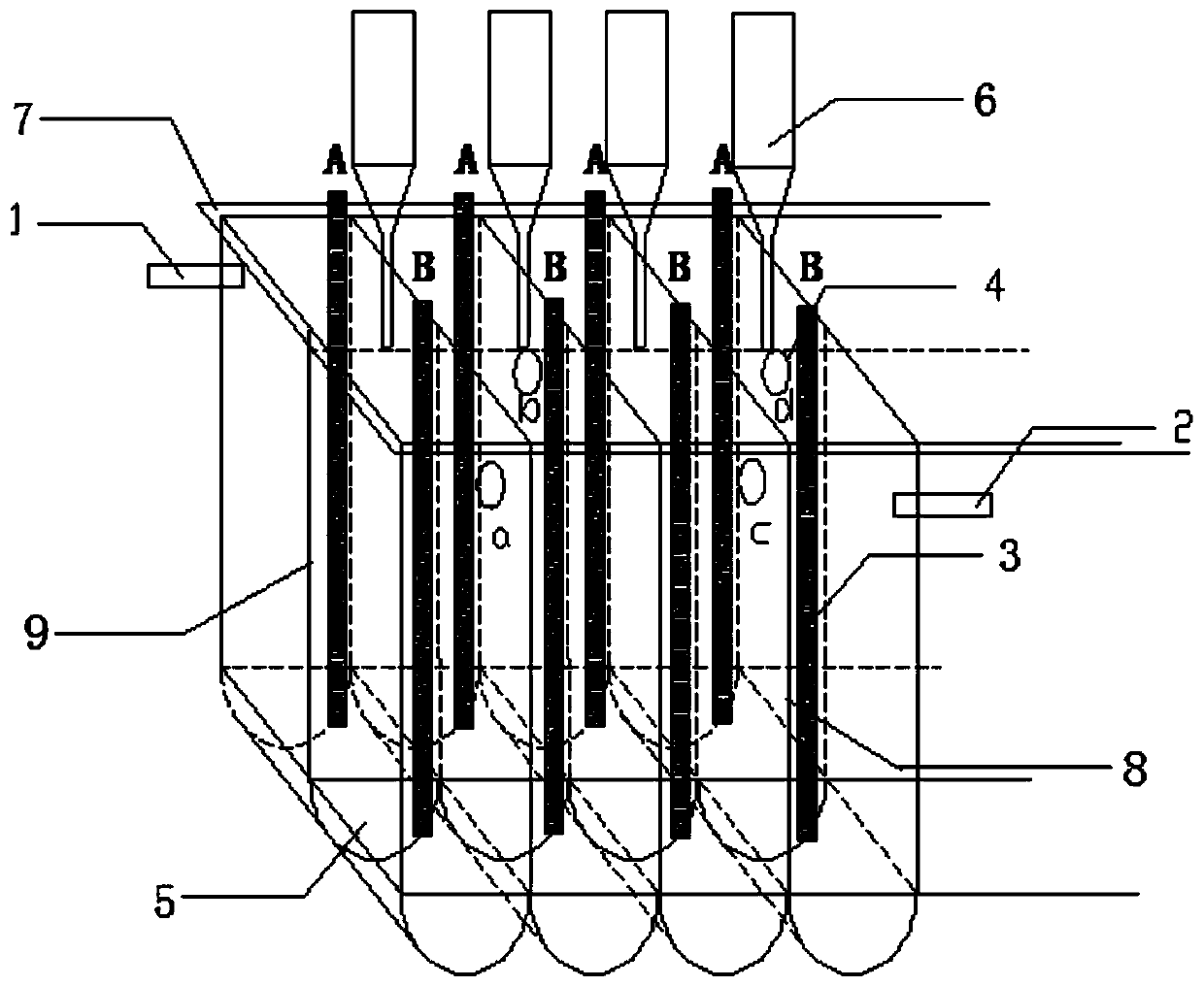

[0045] according to figure 2 The shown structure is provided with an electrolytic cell, and the electrolytic cell is made of quartz glass, and is divided into five tanks by the first dividing plate 8 ( figure 2 Only four tanks are shown in the figure, those skilled in the art can understand that according to figure 2 Five tanks are set in the manner shown). The electrode chamber of the cell body of the electrolytic cell is 58mm long, 40mm wide and 300mm high. The first partition 8 and the second partition 9 are vertically arranged, the second partition 9 has a gap of 20mm from the top, and the bottom has a semicircular communication channel 5 in section. Each cell is divided into two electrode chambers by the second separator 9 . The overflow hole 4 (a, b, c, d) is opened on the upper side of the first partition 8, 50 mm from the top, and the diameter is 10 mm. The overflow hole 4 adjacent to the first partition 8 is opened on the second partition 9 on both sides. A hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com