A method for continuous electrochemical dissolution of palladium powder

An electrochemical and palladium powder technology, applied in the field of continuous electrochemical dissolution of palladium powder, can solve the problems of large consumption of hydrochloric acid and nitric acid, slow dissolution rate of metal Pt, environmental pollution, etc., and achieves simplified operation, high degree of automation, and improved product quality. The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

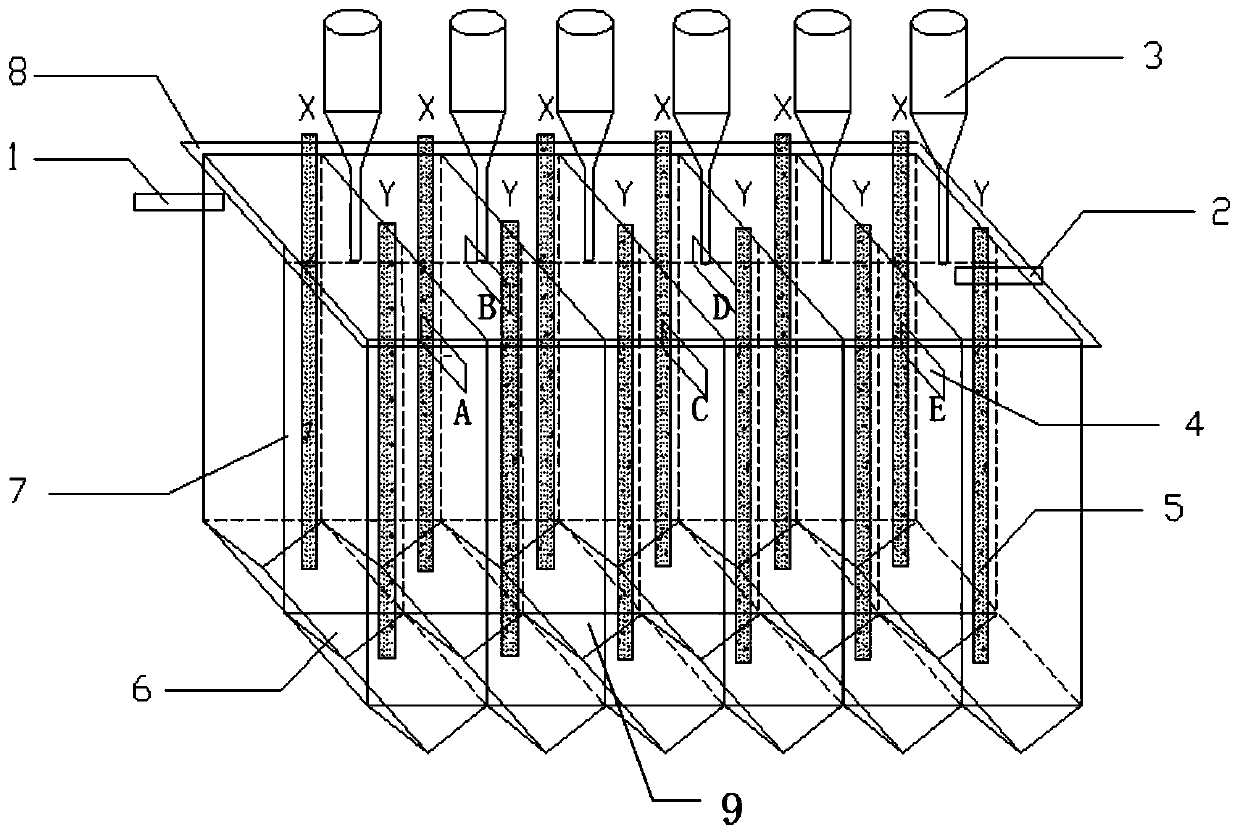

[0033] 1500 grams of palladium powder with a purity of 99.95% are evenly added to the figure 1 The bottoms of the six sets of left and right tanks are shown, and the size of each tank is 170mm×55mm×300mm. Wherein the bottom of the second partition 7 of each cell body is connected in a triangle, and the second partition 7 has a gap of 20 mm from the upper end surface of the electrolytic cell. The overflow hole is opened at a position 50mm away from the upper end surface of the electrolytic cell, and the diameter of the overflow hole is 10mm. Add 8mol / l superior grade pure hydrochloric acid from feed port 1 until all tanks are filled. A total of 12 cylindrical graphite electrodes with a spectral grade of Φ14 mm and a length of 300 mm are selected, fixed on the top cover 8, and the distance between the X and Y electrodes is 120 mm. The two ends of the X and Y electrodes in each tank are respectively loaded with 70V civil alternating current, and the magnitude of the alternating...

Embodiment 2

[0035] 1500 grams of palladium powder with a purity of 99.95% is evenly added to the bottom of the left and right six sets of tanks, each tank having a size of 180mm×50mm×320mm. Wherein the bottom of the second partition 7 of each cell body is connected in a triangle, and the second partition 7 has a gap of 20 mm from the upper end surface of the electrolytic cell. The overflow hole is opened at a position 70mm away from the upper end surface of the electrolytic cell, and the diameter of the overflow hole is 10mm. Add 8mol / l superior grade pure hydrochloric acid from feed port 1 until all tanks are filled. A total of 12 cylindrical graphite electrodes with a spectral grade of Φ14 mm and a length of 300 mm are selected, fixed on the top cover 8, and the distance between the X and Y electrodes is 120 mm. The two ends of the X and Y electrodes in each tank are respectively loaded with 60V civilian alternating current, and the magnitude of the alternating current is 5-25A. Now s...

Embodiment 3

[0037] 1500 grams of palladium powder with a purity of 99.95% is evenly added to the bottoms of the six groups of tanks on the left and right, and the size of each tank is 160mm×55mm×300mm. Wherein the bottom of the second partition 7 of each cell body is connected in a triangle, and the second partition 7 has a gap of 20 mm from the upper end surface of the electrolytic cell. The overflow hole is opened at a position 30mm away from the upper surface of the electrolytic cell, and the diameter of the overflow hole is 10mm. Add 10mol / l superior grade pure hydrochloric acid from feed port 1 until all tanks are filled. A total of 12 cylindrical graphite electrodes with a spectral grade of Φ12 mm and a length of 300 mm are selected, fixed on the top cover 8, and the distance between the X and Y electrodes is 120 mm. The two ends of the X and Y electrodes in each tank are respectively loaded with 80V civilian alternating current, and the magnitude of the alternating current is 5-25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com