Catalyst for vinyl polymerization and preparation method thereof

A technology of ethylene polymerization and catalyst, which is applied in the field of ethylene polymerization catalyst and its preparation method, which can solve the problems of high toxicity and high requirements for operating conditions, and achieve simplification of raw materials and processes, shortening of washing and filtration time, and shortening of the preparation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

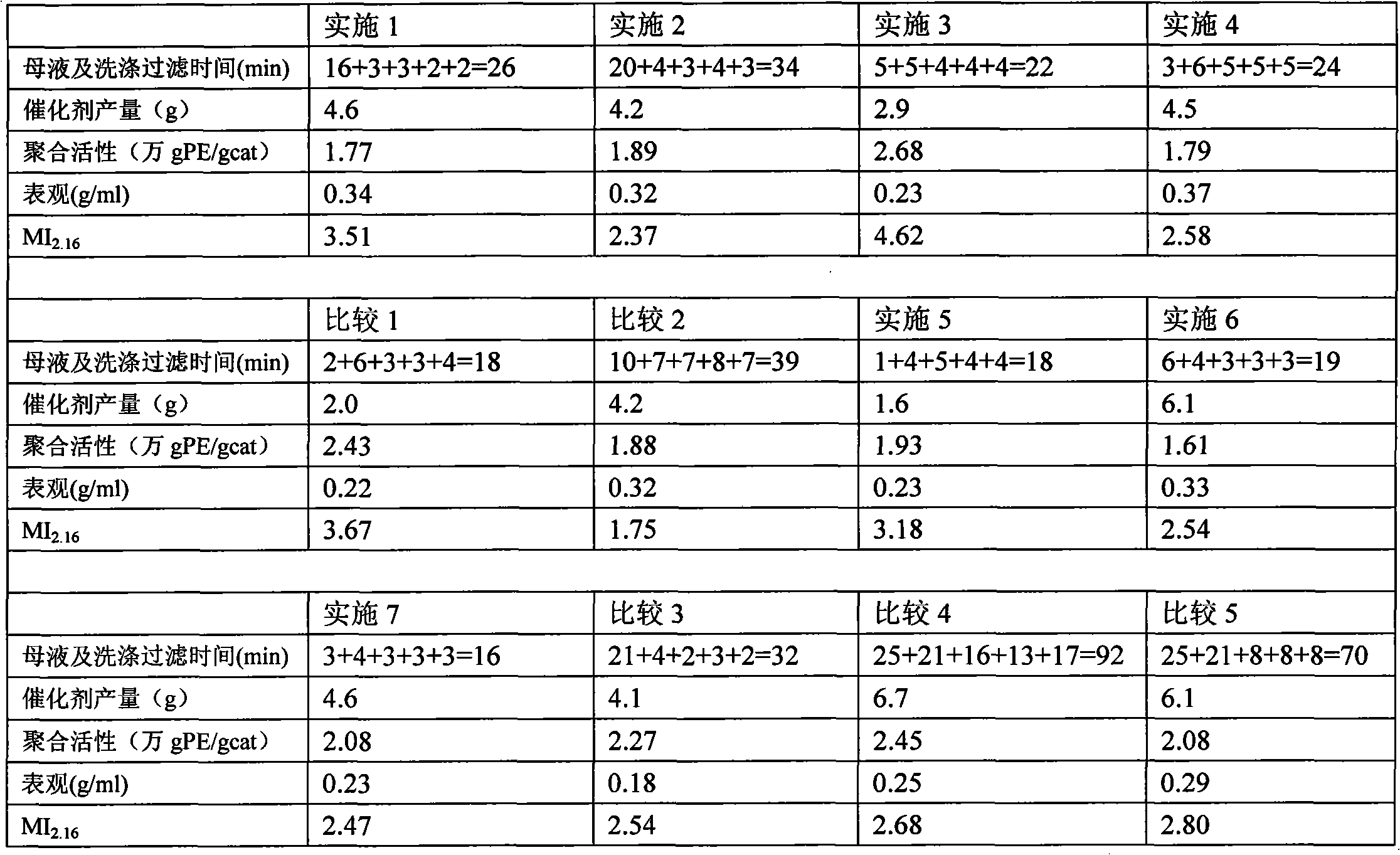

Examples

Embodiment 1

[0029] Embodiment 1: After high-purity N 2 In the fully replaced reactor, sequentially add 0.0210mol anhydrous MgCl 2 , 0.246mol n-decane, add 0.0765mol 2-ethylhexanol under stirring, raise the temperature to 115°C, maintain for half an hour, add 0.00119mol nano-nickel powder, maintain for half an hour, cool down to 50°C, add 0.0131mol SiCl 4 , the solution was cooled to -10°C, and then 0.448mol of titanium tetrachloride was dropped into it, maintained for 1 hour, then heated to 120°C, maintained for 1 hour, filtered, washed with hexane for 4 times, and dried in vacuum to obtain solid catalyst.

Embodiment 2

[0030] Embodiment 2: After high-purity N 2 In the fully replaced reactor, sequentially add 0.0210mol anhydrous MgCl 2 , 0.295mol n-decane, add 0.0765mol 2-ethylhexanol under stirring, raise the temperature to 115°C, maintain for half an hour, add 0.000852mol nano nickel powder, maintain for half an hour, cool down to -10°C, add 0.0175mol SiCl 4 , maintained for half an hour, then 0.358 mol of titanium tetrachloride was dropped into it, maintained for half an hour, then raised to 110°C, maintained for 1 hour, filtered, washed with hexane four times, and vacuum-dried to obtain a solid catalyst.

Embodiment 3

[0031] Embodiment 3: After high-purity N 2 In the fully replaced reactor, sequentially add 0.0210mol anhydrous MgCl 2 , 0.295mol n-decane, add 0.0765mol 2-ethylhexanol under stirring, raise the temperature to 115°C, maintain for half an hour, add 0.000852mol nano-nickel powder, maintain for half an hour, cool down to -10°C, and dissolve 0.358mol tetrachloride Titanium is dropped into it, maintain for half an hour, add 0.00902mol Si(OEt) 4 , maintained for half an hour, then raised the temperature to 110° C., maintained for 1 hour, filtered, washed with hexane four times, and dried in vacuum to obtain a solid catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com