Long-chain branched poly(p-dioxanone) and preparation method thereof

A technology of polydioxanone and p-dioxanone, which is applied in the field of long-chain branched polydioxanone and its preparation, and can solve the problems of polymer high elasticity, impact strength, elongation at break, etc. Reduced mechanical properties, weakened polymer crystallinity, limited improvement of rheological properties, etc., to improve processing performance, easy to promote, and increase interaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

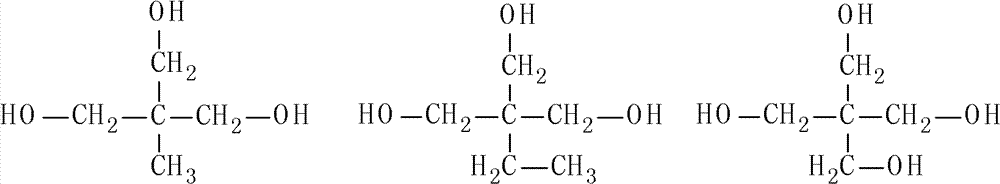

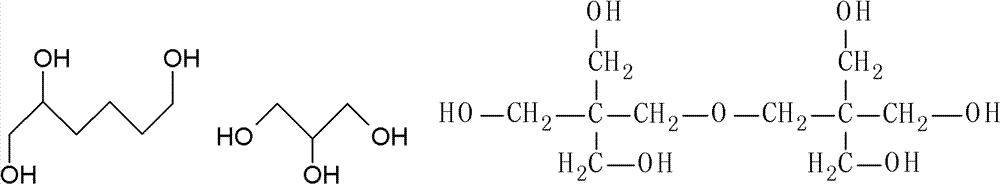

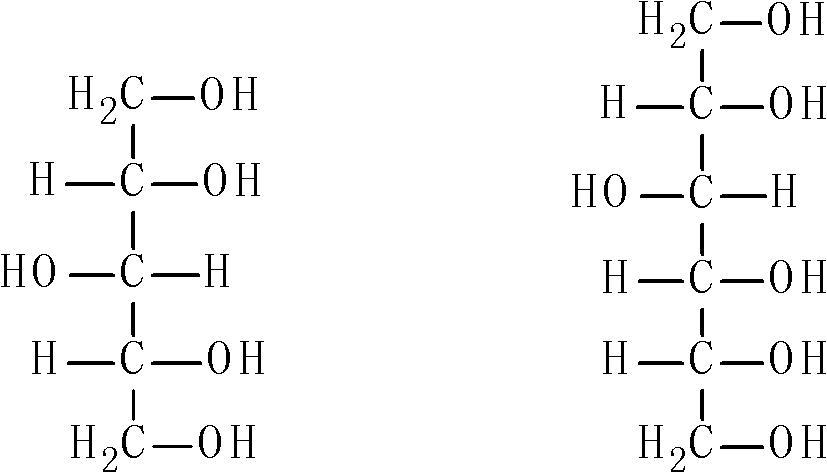

Method used

Image

Examples

Embodiment 1

[0037] Add trimethylolpropane and p-dioxanone in a molar ratio of 1:60 to the reaction vessel, raise the temperature to 80°C for 15 minutes under the protection of an inert gas, and then add the molar ratio of p-dioxanone to 1: 0.002 catalyst stannous octoate, continue to stir and react at 80°C for 48 hours, the crude product obtained after cooling is dissolved in phenol / tetrachloroethane with a volume ratio of 1:1, purified by methanol precipitation and dried to obtain the number average Polydioxanone (a-PPDO) with a molecular weight of 5234 and a star-shaped multi-armed hydroxyl group.

[0038] Add the obtained a-PPDO and benzyl-terminated hydroxyl-terminated polylactic acid with a number-average molecular weight of 2412 in a molar ratio of 1:1 into the reaction vessel, and then under the protection of an inert gas, put them in an oil bath at 150°C until the two are completely melted Afterwards, HDI was added in a ratio of 1:1.4 to a-PPDO and benzyl-terminated hydroxyl-termi...

Embodiment 2

[0040] Add trimethylolethane and p-dioxanone in a molar ratio of 1:10 to the reaction vessel, raise the temperature to 60°C for 20 minutes under the protection of an inert gas, and then add the molar ratio of p-dioxanone 1:0.001 catalyst triethylaluminum, continue to stir and react at 60°C for 24 hours, the crude product obtained after cooling is purified by the method described in Example 1 and then dried to obtain a-PPDO with a number average molecular weight of 1100.

[0041] Add the obtained a-PPDO and methyl-terminated hydroxyl-terminated polyethylene glycol with a number average molecular weight of 500 in a molar ratio of 1:1.2 into the reaction vessel, and then under the protection of an inert gas, in an oil bath at 110°C, wait for both After it is completely melted, add XDI which is 1:0.6 in terms of the number of moles of total hydroxyl groups in a-PPDO and methyl-terminated hydroxyl-terminated polyethylene glycol, and react for 1 hour to obtain long-chain branched pol...

Embodiment 3

[0043] Add pentaerythritol and p-dioxanone in a molar ratio of 1:1000 to the reaction vessel, raise the temperature to 80°C for 30 minutes under the protection of an inert gas, and then add dioxanone in a molar ratio of 1:0.001 Catalyst tetrabutyltitanium, continue to stir and react at 80°C for 48 hours, the crude product obtained after cooling is purified by the method described in Example 1 and then dried to obtain a-PPDO with a number average molecular weight of 100214.

[0044] The obtained a-PPDO and the phenyl-terminated hydroxyl-terminated polymethyl carbonate with a number average molecular weight of 11600 were added to the reaction vessel in a molar ratio of 1:1.5, and then under the protection of an inert gas, they were placed in an oil bath at 170°C for two After it is completely melted, add HMDI with a-PPDO and phenyl-terminated hydroxyl-terminated polydimethylcarbonate whose molar number of total hydroxyl groups is 1:1.2, and react for 1 hour to obtain long-chain b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com