Nonionic water-based color restoration agent for colored pavement and preparation process thereof

A non-ionic, color repair technology, applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of polluted environment, easy to be polluted, low bonding strength, etc., achieve simple preparation equipment, reduce production Cost and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

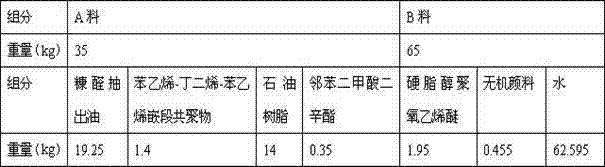

[0023] The raw materials that will produce 100kg non-ionic water-based colored pavement color restoration agent are as follows:

[0024]

[0025] Its preparation process is as follows:

[0026] Preparation of material A: clean up the stirring equipment first, then add 16.5kg of furfural extract oil, 1.2kg of styrene-butadiene-styrene block copolymer, 12kg of petroleum resin, and dioctyl phthalate to the stirring equipment 0.3kg of raw material, during the addition process, the stirring equipment kept stirring, and the above mixture was heated to 170°C, stirred at 170°C for 60 minutes, and 30kg of material A cement was prepared by shearing;

[0027] Preparation of Material B: Mix and stir 2.1 kg of stearyl polyoxyethylene ether as an emulsifier, 0.49 kg of inorganic pigment, and 67.41 kg of water to prepare 70 kg of material B soap;

[0028] First follow the steps The prepared material A is heated to 140°C, follow the steps The prepared material B is heated to 60°...

Embodiment 2

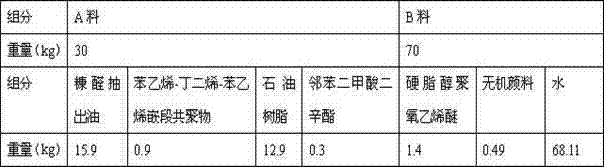

[0030] The raw materials that will produce 100kg non-ionic water-based colored pavement color restoration agent are as follows:

[0031]

[0032] Its preparation process is as follows:

[0033] Preparation of material A: clean up the mixing equipment first, then add 15.9kg of furfural extract oil, 0.9kg of styrene-butadiene-styrene block copolymer, 12.9kg of petroleum resin, dioctyl phthalate to the mixing equipment The raw material of ester 0.3 kg, the stirring equipment kept stirring during the addition process, and the above mixture was heated to 170°C, stirred at 170°C for 60 minutes, and 30kg of material A cement was prepared by shearing;

[0034] Preparation of material B: 1.4 kg of stearyl polyoxyethylene ether as an emulsifier, 0.49 kg of inorganic pigment, and 68.11 kg of water were mixed and stirred to prepare 70 kg of material B soap;

[0035] First follow the steps The prepared material A is heated to 140°C, follow the steps The prepared material B is...

Embodiment 3

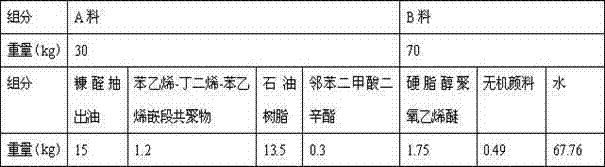

[0037] The raw materials that will produce 100kg non-ionic water-based colored pavement color restoration agent are as follows:

[0038]

[0039] Its preparation process is as follows:

[0040] Preparation of material A: clean up the stirring equipment first, then add 15kg of furfural extract oil, 1.2kg of styrene-butadiene-styrene block copolymer, 13.5kg of petroleum resin, and dioctyl phthalate to the stirring equipment 0.3 kg of raw material, the stirring equipment kept stirring during the addition process, and the above mixture was heated to 170°C, stirred at 170°C for 60 minutes, and 30kg of material A cement was prepared by shearing;

[0041] Preparation of Material B: Mix and stir 1.75 kg of stearyl polyoxyethylene ether as an emulsifier, 0.49 kg of inorganic pigment, and 67.76 kg of water to prepare 70 kg of material B soap;

[0042] First follow the steps The prepared material A is heated to 140°C, follow the steps The prepared material B is heated to 60°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com