Short flax fiber degumming and bleaching process

A technology for short fibers and flax, applied in the field of flax spinning raw material processing, can solve the problems of affecting the color of dyed fabrics, insufficient bleaching, inability to remove fiber lignin and pectin, etc., so as to improve dyeing and printing quality and improve fiber fineness. , the effect of increasing the degree of bleaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

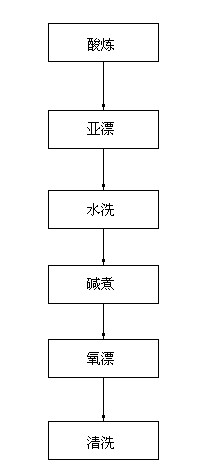

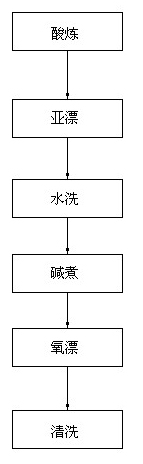

Image

Examples

Embodiment

[0016] Embodiment: a kind of flax staple fiber degumming and bleaching process, take flax staple fiber as processing object, and its concrete process is as follows:

[0017] (1) Preparation materials:

[0018] ① Prepare the pickling solution used in the pickling step; the proportion of water, sulfuric acid and penetrating agent is 5000~7000 : 20~30 : 3~10 by weight (Kg), and the concentration of sulfuric acid is ≥ 92% by mass , and first add water and sulfuric acid in the container, then add penetrant, stir evenly, and set aside;

[0019] ② Prepare the sub-bleaching solution used in the sub-bleaching step; first mix the sodium chlorite solution evenly according to the weight (Kg) ratio of water and sodium chlorite in 5000~7000: 10~30, and sodium chlorite content of ≥ 80% by mass, the pickling solution and sodium chlorite solution are prepared by mixing 5000 to 7000: 10 to 20 parts by weight (Kg) and prepared for subsequent use;

[0020] ③ Prepare the alkali boiling solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com