Method for processing soft foundation by combining electrochemical grouting with slurry-cemented discrete material pile

A bulk material pile, electrochemical technology, applied in soil protection, foundation structure engineering, construction, etc., to achieve the effect of improving the strength of the soil around the pile, prolonging the solidification time, and shortening the construction machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited only to the description of this embodiment.

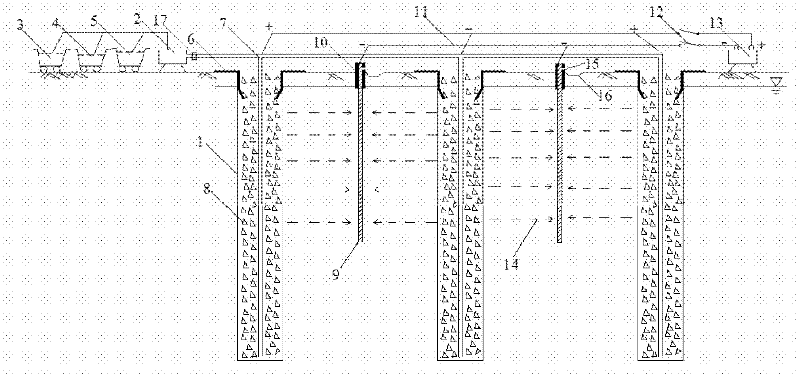

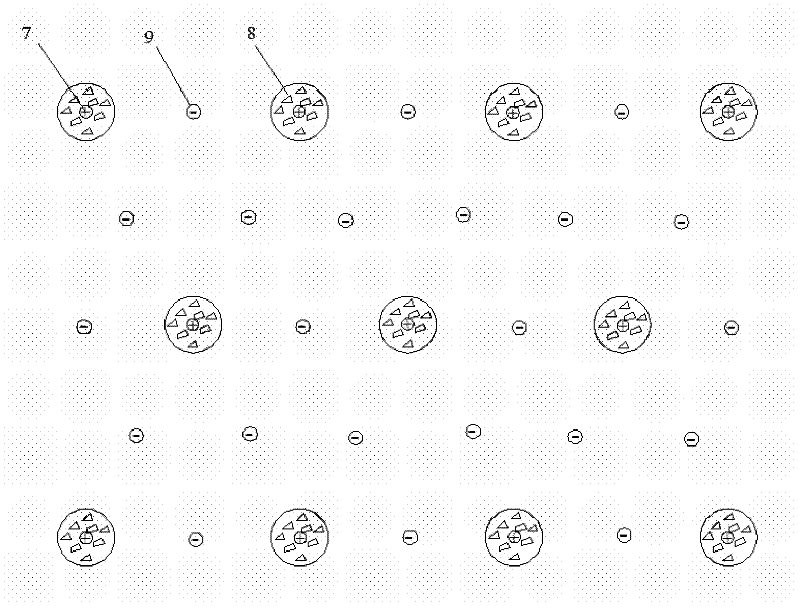

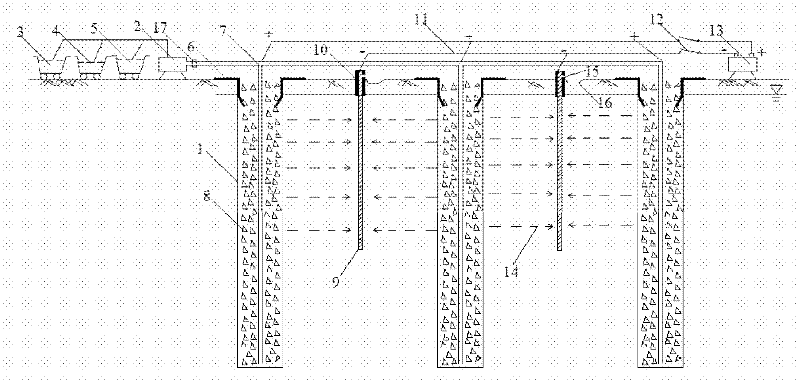

[0020] Such as figure 1 and figure 2 As shown, when implementing, first use the drilling rig to drill the hole (1) to the design depth according to the design diameter, and use mud (3) to protect the wall, and place the pile top made of steel plate on the top of the hole (1) and above the groundwater level line Hole wall casing (6), put the grouting pipe (7) into the borehole (1), the grouting pump (2) and the grouting pipe (7) are connected by the connecting valve (17), through the grouting pump (2) Put clear water (4) into the grouting pipe (7) to clean the borehole (1), and then put in well-graded crushed stones or bricks and other construction waste or waste steel slag and other coarse-grained aggregate materials (8); The electric g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com