Synchronous control device of revolving speed of hydraulic walking mechanism engine and discharge of main pump

A technology of engine speed and synchronous control, which is applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc., can solve problems such as the inability to realize synchronous and coordinated control of engine speed, achieve fuel consumption savings, reduce operating procedures, and avoid stalling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

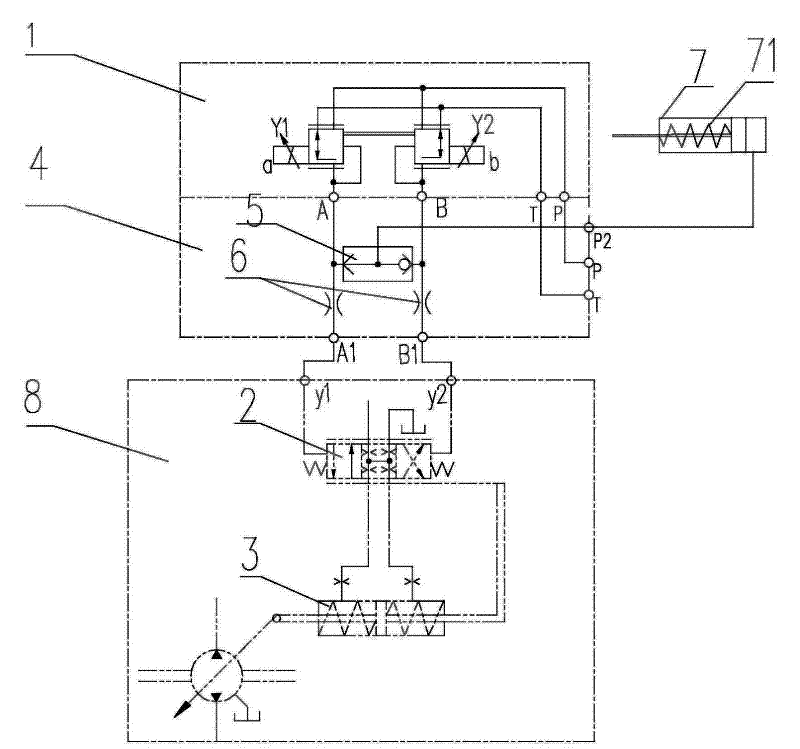

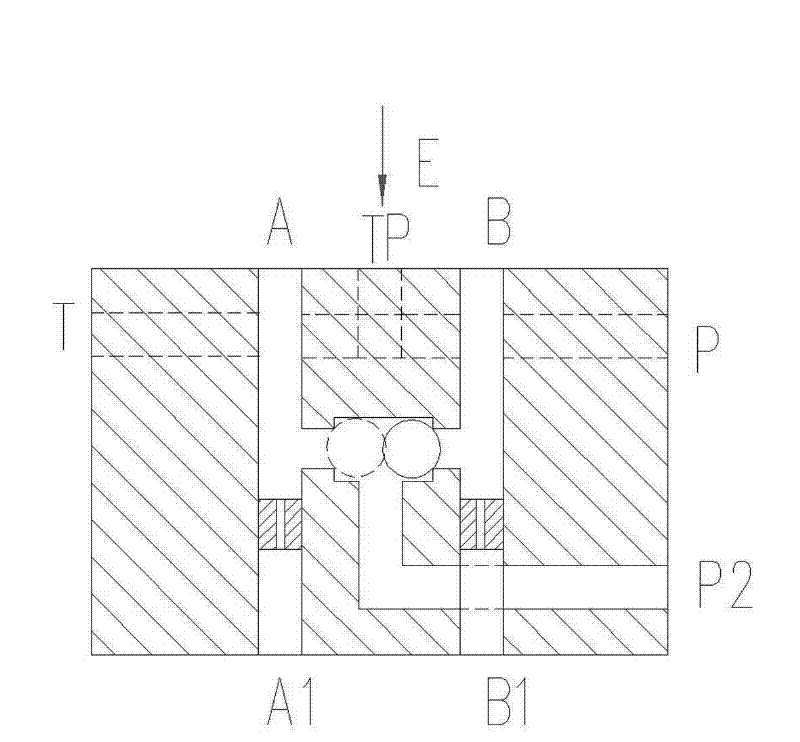

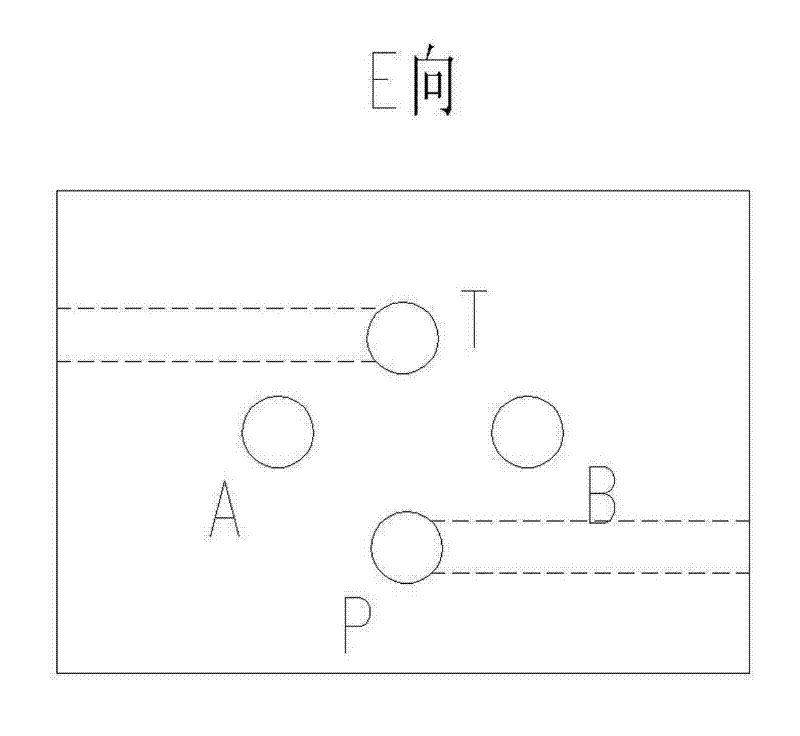

[0012] like figure 1 As shown in the figure, the main pump 8 is the power component of the driving locomotive in the system, and it has two external control ports y1, y2, which are the control ports of the variable servo valve 2 of the main pump; the proportional pressure reducing valve 1 It is a standard hydraulic component, which adopts explosion-proof proportional decompression (DHRZA / M-A-012) imported from Italy. It has 4 oil ports, P T A B. The P port of proportional decompression valve 1 is connected to the pilot pressure oil inlet port, and the oil return port T Oil tank; port A and port B are the output ports of the proportional pressure reducing valve, which reflect the magnitude of the input electrical signal, and are respectively connected to the control ports y1 and y2 of the variable servo valve 2 of the main pump. The change of y1 and y2 makes the valve output a differential pressure signal to control the pump variable Piston 3 realizes the variable control of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com