Terminal protection structure of super-junction semiconductor device and fabrication method thereof

A terminal protection structure and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., to achieve high device withstand voltage characteristics, device withstand voltage improvement, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

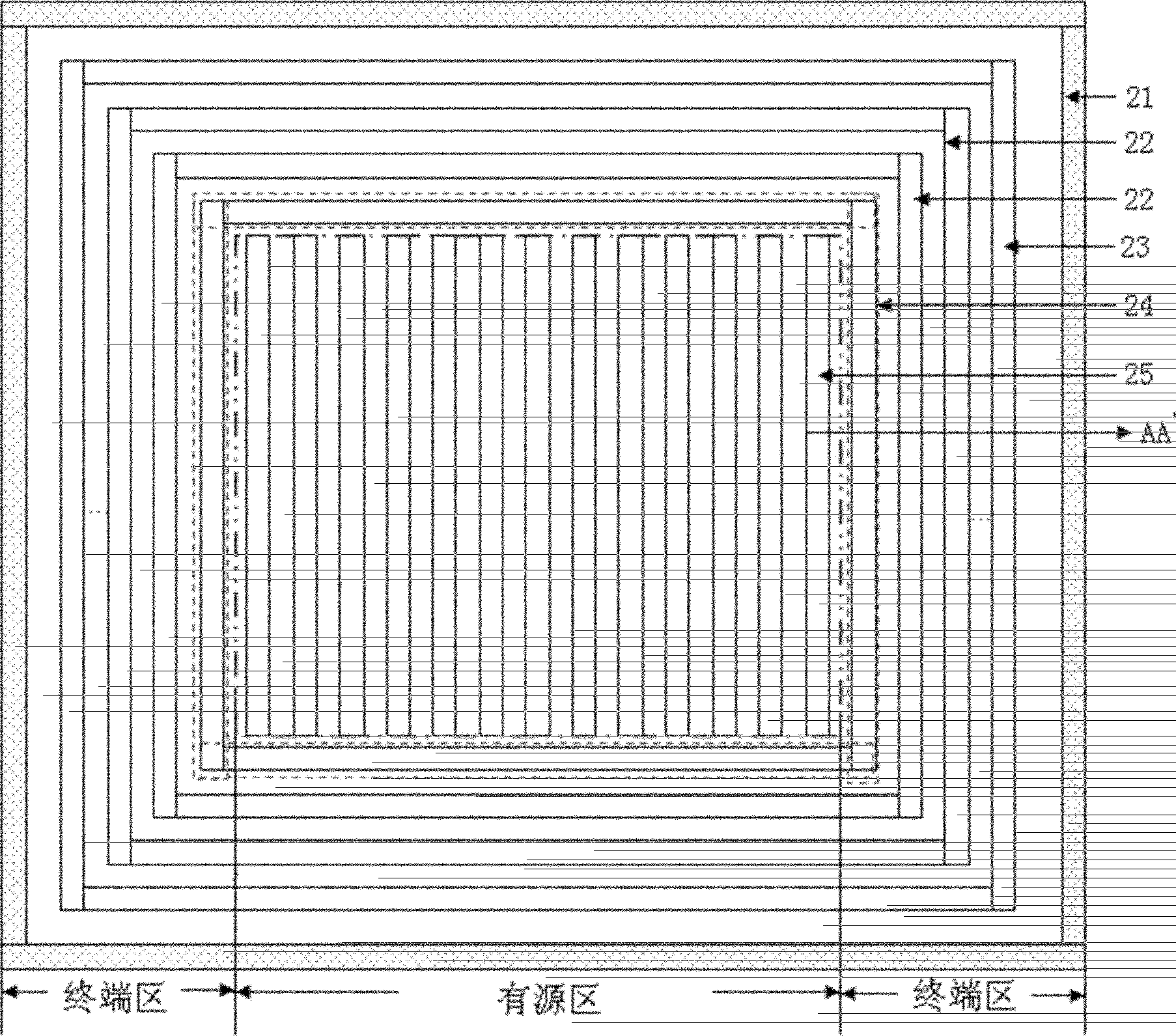

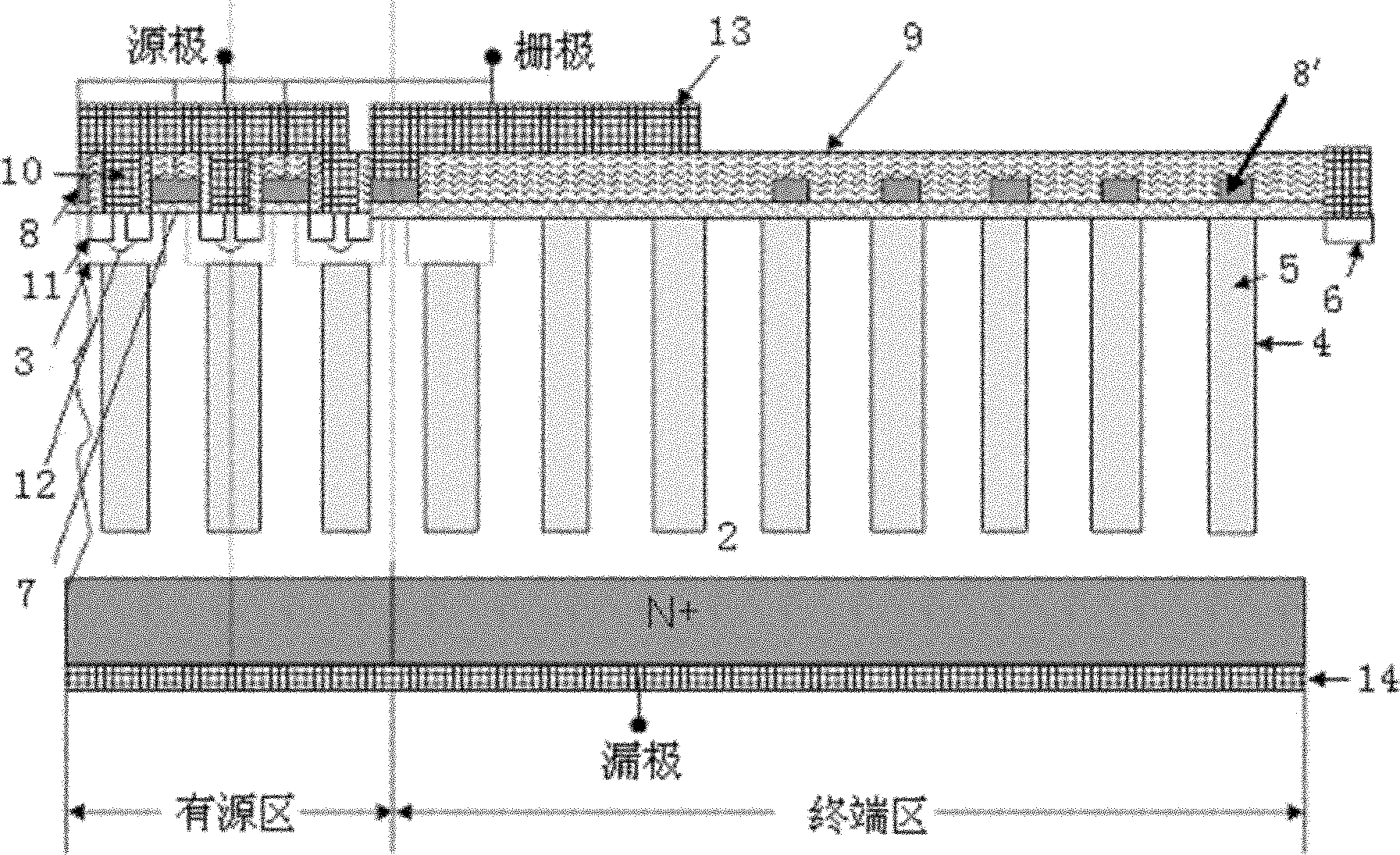

[0034] Embodiment one, see image 3 , 4 As shown, the terminal protection structure of the super junction semiconductor device in this embodiment includes: a channel stop ring 21 located at the outermost end of the terminal region, a P-type annular groove 23 located in the channel stop ring 21, and a channel stop ring 23 located in the channel stop ring 21. The P-type annular groove 22 (generally a plurality of grooves) inside the annular groove 23, the P-type ring 24 located in the P-type annular groove 22; the annular groove 23 has at least two depths Like the grooves, grooves 23 have at least two different depths from the set of grooves in grooves 22 . The active area trench 25 located in the active area is disposed in the P-type ring 24 . The channel stop ring 21 , the annular groove 23 , the annular groove 22 , and the P-ring 24 are all square with four corners being right angles. The P-type annular grooves 23 and 22 together serve as a charge balance compensation P-ty...

Embodiment 2

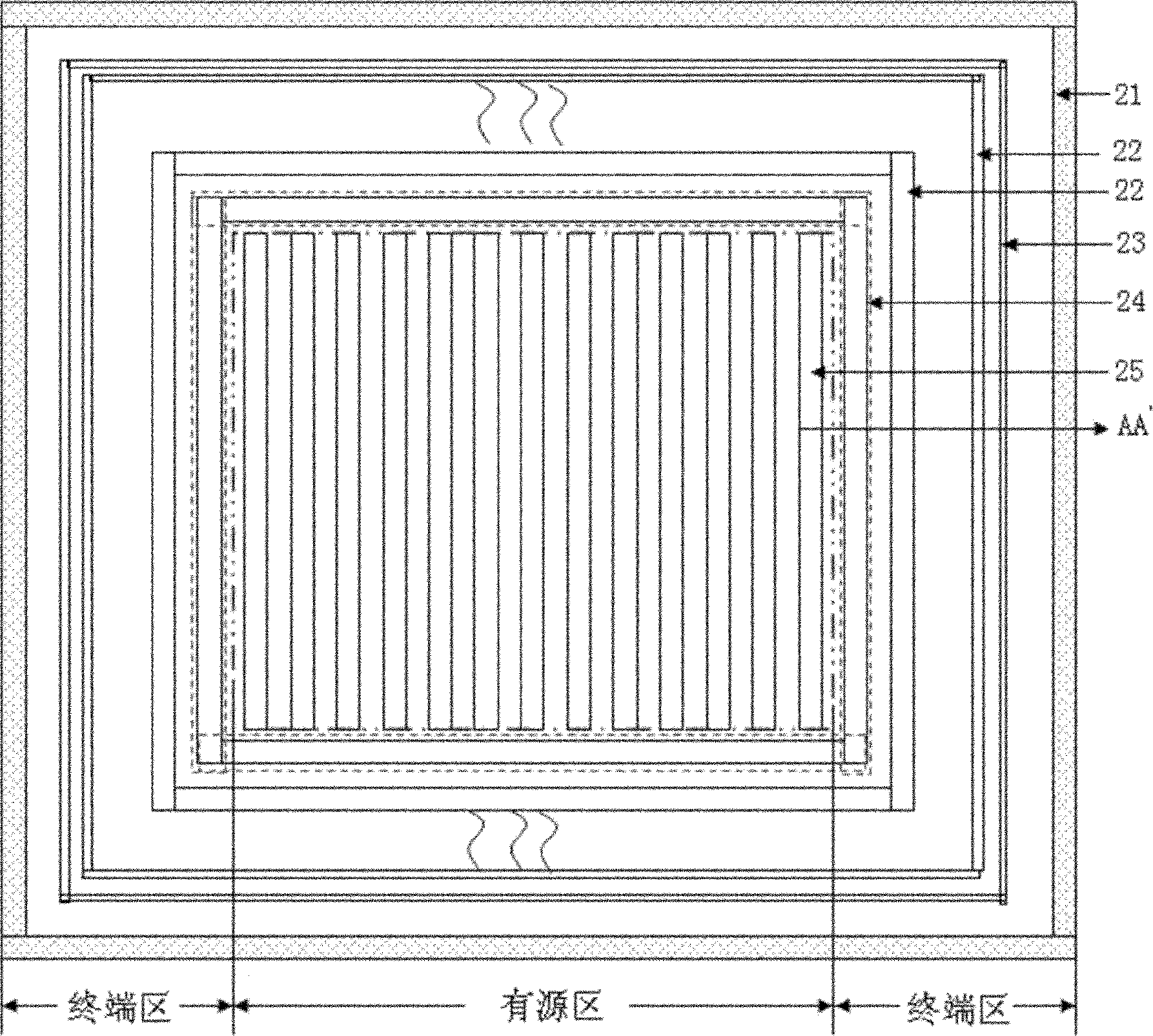

[0037] Embodiment two, such as Figure 6 As shown, the difference between the present embodiment and the first embodiment is that the shape of the annular groove 23 and the annular groove 22 in the structure of the terminal area is improved, and the four corners in the first embodiment are improved to be right-angled. The arc shape with a certain radian can further reduce the electric field intensity at the corner and increase the breakdown voltage of the device. In this embodiment, the four corners of the P-shaped ring 24 are also changed into circular arcs with a certain radian.

[0038] Implementation three, such as Figure 7 Shown, based on the plan view of embodiment one and embodiment two (see image 3 , 6 ), the position of the polysilicon field plate 8' is improved, and a polysilicon field is covered above the junction of each P / N thin layer (that is, the junction of the P-type semiconductor thin layer and the N-type semiconductor thin layer) outside the terminal re...

Embodiment 5

[0040] Embodiment five, such as Figure 9 As shown, on the basis of the third embodiment, all the field plates in the terminal area are changed to metal field plates, that is, the polysilicon field plate 8' located above the gate oxide film 7 is canceled, and the interlayer dielectric film 9 outside the terminal area A metal field plate 13' is provided at the junction of each P / N thin layer above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com