Semiconductor structure and manufacturing method thereof

A semiconductor and conductive pad technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc. The problem of large bending degree of wire can achieve the effect of avoiding offset and dumping, avoiding oxidation or corrosion, and alleviating bending arc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

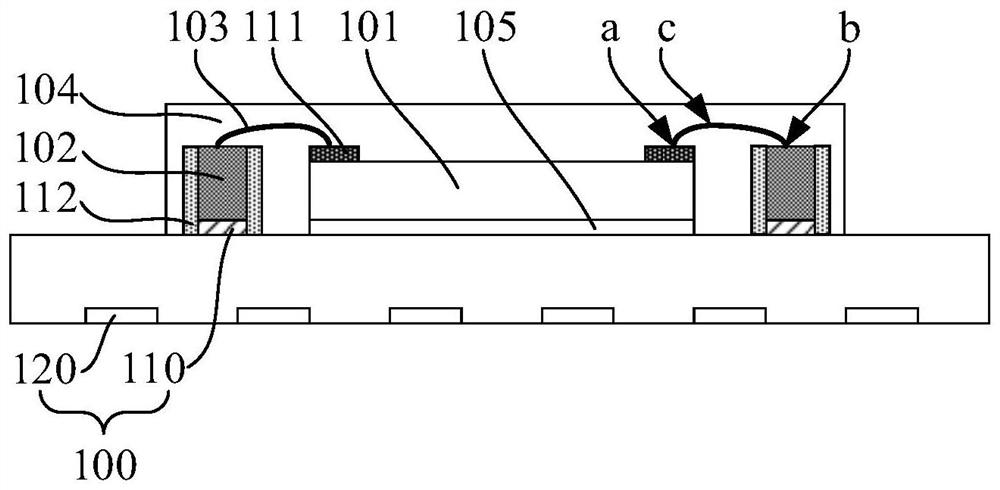

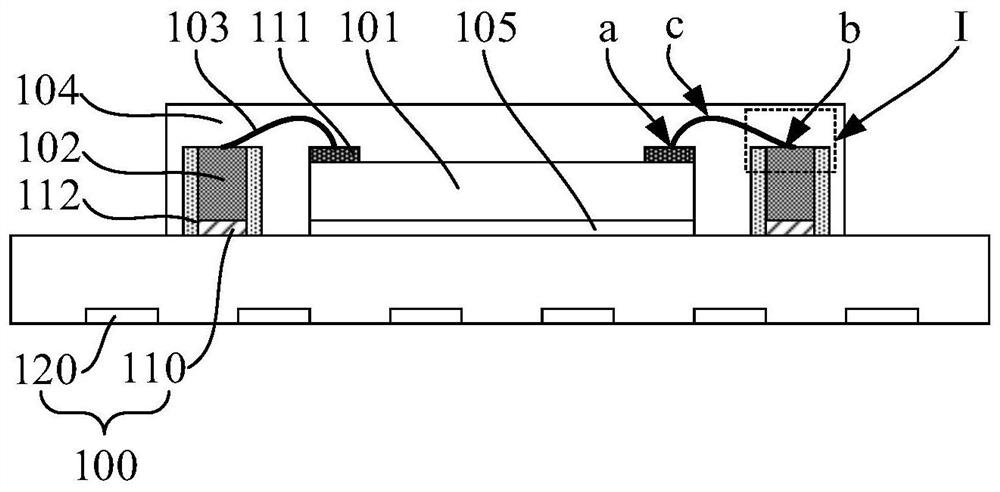

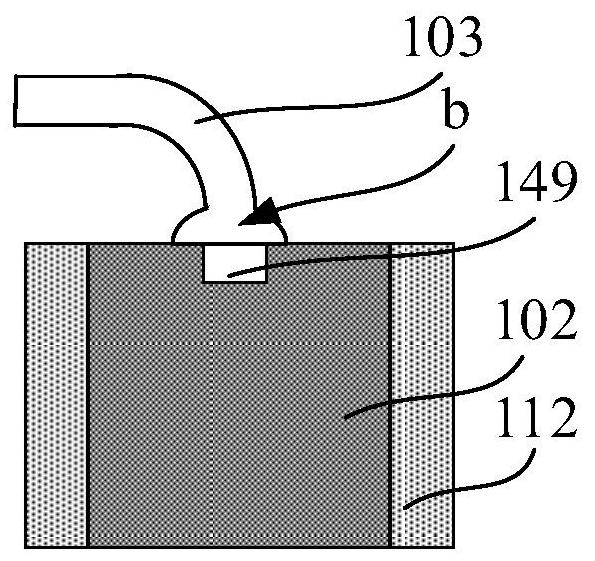

[0014] It can be seen from the background art that the current connection strength between the lead wire and the I / O terminal of the chip and the package pin or the pad on the substrate needs to be improved, and the stability of the semiconductor structure needs to be improved.

[0015] After analysis, it is found that in order to pursue higher packaging integration, the distance between the I / O terminal of the chip and the package pin or the pad on the substrate will inevitably be further reduced. At this time, the height difference between the I / O terminal of the chip and the package pin or the pad on the substrate will further increase the bending of the lead connecting the I / O terminal of the chip and the package pin or the pad on the substrate. The degree makes it easier for the lead to crack due to excessive bending at the I / O end of the chip and the package pin or the pad on the substrate.

[0016] In order to solve the above problems, the present invention provides a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com