Integrally-moving high-voltage variable-frequency electric control device

A high-voltage frequency conversion, electronic control device technology, applied in the direction of AC motor control, electrical components, control systems, etc., can solve the problems of time-consuming, reduced motor current, poor working stability and reliability, etc., to shorten the installation time and ensure operation. Safe, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

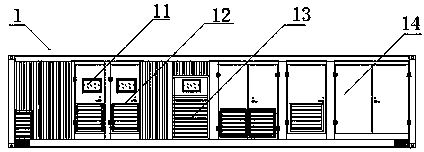

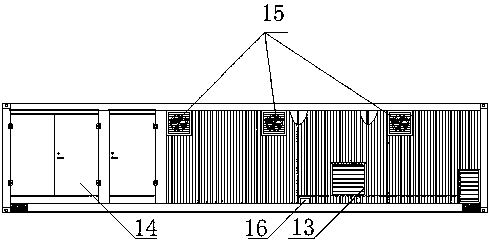

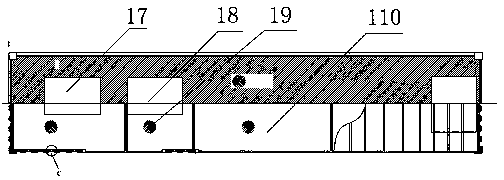

[0028] Such as Figure 1~5 As shown, an integral mobile high-voltage frequency conversion electric control device is to install the excitation inrush current suppression cabinet, transformer cabinet, power cabinet and control cabinet in a housing; the front of the housing 1 is provided with a perspective window 11 and a movable louver 12 , fixed louver 13 and cabinet door 14; fixed louver 13, cabinet door 14, fan 15 and wire inlet and outlet holes 16 are provided at the back; fixed shutter 13, fan 15 and wire inlet and outlet hole 16 are provided on the left side The right side is provided with an exhaust fan 114 and an inlet and outlet hole 16; the top plate is provided with an equipment inlet and outlet hole 17 and a fan hole 18, and the inner bottom surface is provided with an electrostatic floor 19, an insulating rubber pad 110 and an air conditioner external unit 111, and the side of the housing 1 The board is composed of two steel plates and an insulation layer arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com