Method for producing alkanolamine salt of a-sulfo fatty acid alkyl ester

A technology of sulfo fatty acid alkyl ester and manufacturing method, which is applied in the direction of sulfonate salt preparation, amino hydroxyl compound preparation, chemical instruments and methods, etc., can solve the problems such as easy coloring of α-sulfo fatty acid alkyl ester salt, Achieves the effect of suppressing color tone deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3-1~3-4

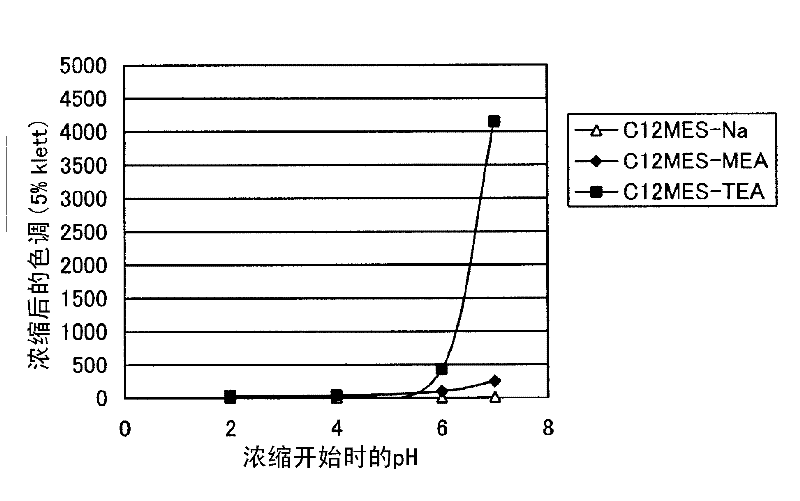

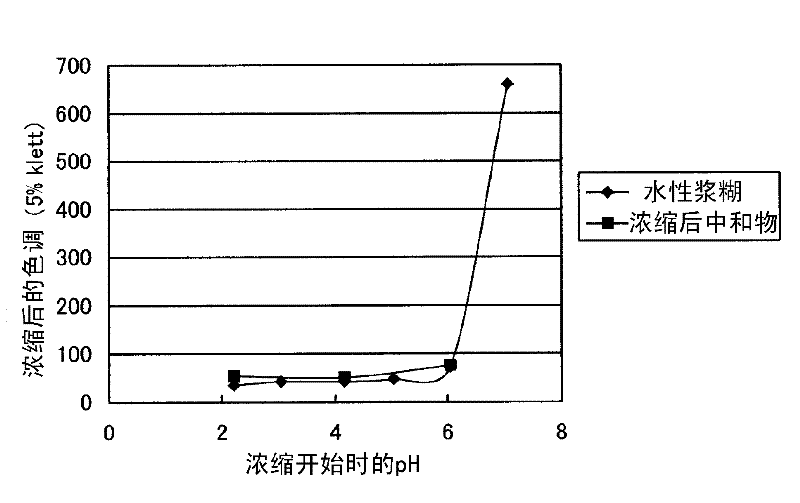

[0157] [Examples 3-1 to 3-4, Reference Example 3-5]

[0158] Put the methyl ester of fatty acid with a chain length of C14 (14 carbon atoms) (manufactured by Lion Co., Ltd., trade name: Pastel M-14) in a tank reactor, and flow it into the reaction solution by nitrogen in an open system. Blow into SO 3 gas, thereby sulfonating the respective methyl esters. The reaction temperature is 80°C, and the reaction molar ratio is SO 3 / methyl ester=1.2, SO 3 The supply rate is about 10g·min -1 . Thereafter, α-sulfofatty acid methyl esters were obtained by performing an aging reaction at 80° C. for 30 minutes. Then with respect to the obtained α-sulfo fatty acid methyl ester, add methanol 20wt%, H 2 o 2 SO 3 Esterification and bleaching of 2-molecule adducts. Add 0.5 mol / L monoethanolamine aqueous solution heated to 50° C. into bleaching acid, adjust the pH of the sample to 6.0, and obtain an aqueous solution containing α-sulfo fatty acid methyl ester monoethanolamine salt. The...

Embodiment 3-6~3-7

[0162] Using methyl ester of fatty acid with chain length C12 (manufactured by Lion Corporation, trade name: Pastel M-12) and methyl ester of fatty acid with chain length C18 (manufactured by Lion Corporation, trade name: Pastel M-180), carry out The same operation as in Example 3-4 was carried out to obtain an aqueous paste containing α-sulfo fatty acid methyl ester monoethanolamine salt. The results of its concentrated AI and hue determination are shown in Table 4.

[0163] [Table 4]

[0164]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com