Method for processing gold tea

A processing method, the technology of golden tea, applied in tea treatment before extraction, etc., can solve the problems of low economic value, low market share, waste of resources, etc., and achieve improved economic benefits, thick and fresh yellow tea, reddish brown black in color moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

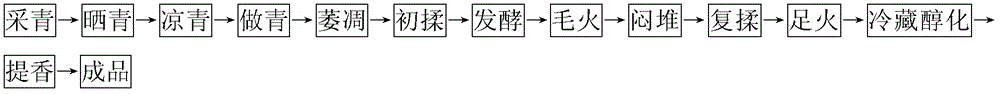

[0028] The processing method of golden tea of the present invention is carried out according to the sequence of following steps:

[0029] 1. Green picking: Pick 2 to 4 leaves after one bud and one leaf from the new shoot of Fuyun No. 6 tea tree, and clip the leaves when they are of the same tenderness.

[0030] 2. Green drying: Put the picked tea leaves outside with a dustpan, dry them for 30-40 minutes, and control the weight loss rate of the green tea at 6% to 9%. From 3:30 to 5:30 in the afternoon, the appropriate temperature is 25°C to 28°C. The sun is too strong. When the temperature exceeds 32°C, add a sunshade net with a thickness of 3 to 5cm.

[0031] 3. Cool green: place the dried tea leaves in a room at 18-23°C, the room temperature is controlled by the air conditioner, and the cooling time is 60-90 minutes.

[0032] 4. Greening: After the cooling is completed, shake the tea leaves for 3 times. The first shake is 5 minutes, the speed is 8 rpm, and the green is spr...

Embodiment 2

[0043] The processing method of golden tea of the present invention is carried out according to the sequence of following steps:

[0044] 1. Picking green: picking 2-4 leaves after the new shoot, one bud and one leaf of Fuyun No. 6 tea tree, and clamping the leaves at the same tenderness;

[0045] 2. Green drying: Put the picked tea leaves outside with a dustpan and dry them for 35 minutes. The weight loss rate of the green tea leaves should be controlled at 7% to 8%. :30-4:30, the best temperature is 25°C-28°C, the sun is too strong, and when the temperature exceeds 32°C, add a sunshade net with a thickness of 4-5cm.

[0046] 3. Cooling: place the dried tea leaves in a room at 18-22°C, the room temperature is controlled by the air conditioner, and the cooling time is 80-90 minutes;

[0047] 4. Greening: After the cooling is completed, shake the tea leaves for 3 times, the first shake for 6 minutes, the speed is 6 rpm, and the greening is 50 minutes; the second shake is 11 ...

Embodiment 3

[0058] The processing method of golden tea of the present invention is carried out according to the sequence of following steps:

[0059] 1. Green picking: Pick 3-4 leaves after the new shoot of Fuyun No. 6 tea tree, one bud and one leaf, and clip the leaves when they are of the same tenderness.

[0060] 2. Green drying: Put the picked tea leaves outside with a dustpan, dry them for 30-35 minutes, and control the weight loss rate of the green tea at 6% to 8%. From 4:00 to 5:00 in the afternoon, the appropriate temperature is 26°C to 28°C. The sun is too strong. When the temperature exceeds 32°C, add a sunshade net with a thickness of 3 to 4cm.

[0061] 3. Cool green: place the dried tea leaves in a room at 18-23°C, the room temperature is controlled by the air conditioner, and the cooling time is 65-85 minutes.

[0062] 4. Greening: After the cooling is completed, shake the tea leaves for 3 times. The first shake is 5 minutes, the speed is 10 rpm, and the green is spread fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com