System for manufacturing sulphur by utilizing carbon and sulfur-containing flue gas

A technology of sulfur and carbon materials, which is applied in the preparation/purification of sulfur, chemical instruments and methods, and the separation of dispersed particles, etc., which can solve the problems of polluting the environment, difficult treatment of by-product desulfurized gypsum, and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

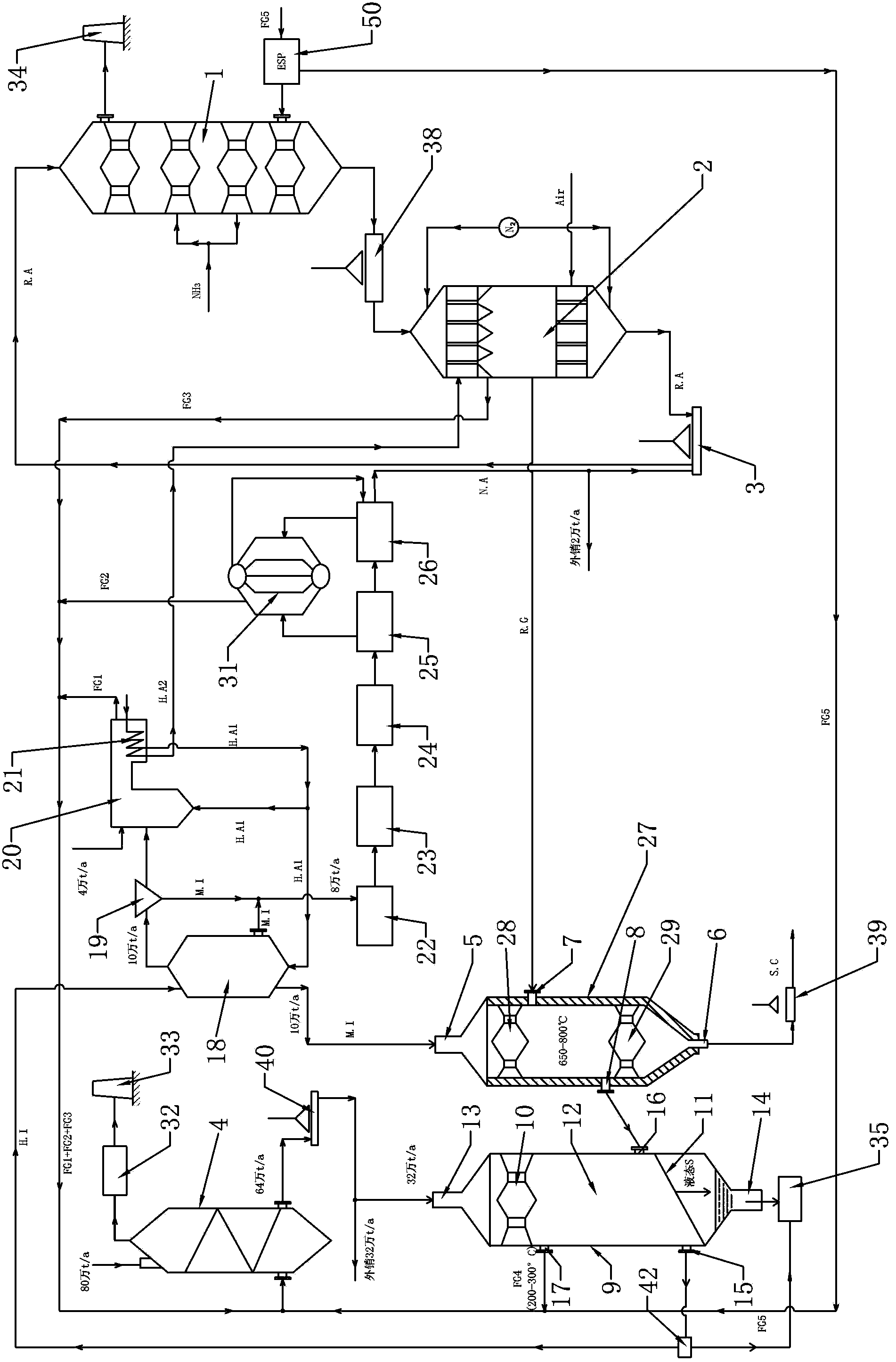

[0019] The system for producing sulfur by using carbon materials and sulfur-containing flue gas includes a flue gas desulfurization component, a sulfur production component, an upgrading component and an active coke production component.

[0020] Such as figure 1 As shown, the flue gas desulfurization assembly includes an adsorption tower 1, an analysis tower 2, a first screening and dust removal device 3 and a second screening and dust removal device 38, and the discharge port at the bottom of the adsorption tower 1 is connected to the second screening and dust removal device 38. Feed port is connected, and the discharge port of the second screening and dedusting device 38 is connected with the feed port on the top of the analysis tower 2, and the bottom discharge port of the analysis tower 2 is communicated with the feed port of the first screening and dust removal device 3, the second A discharge port of a screening dust removal device 3 communicates with a feed port at the...

Embodiment 2

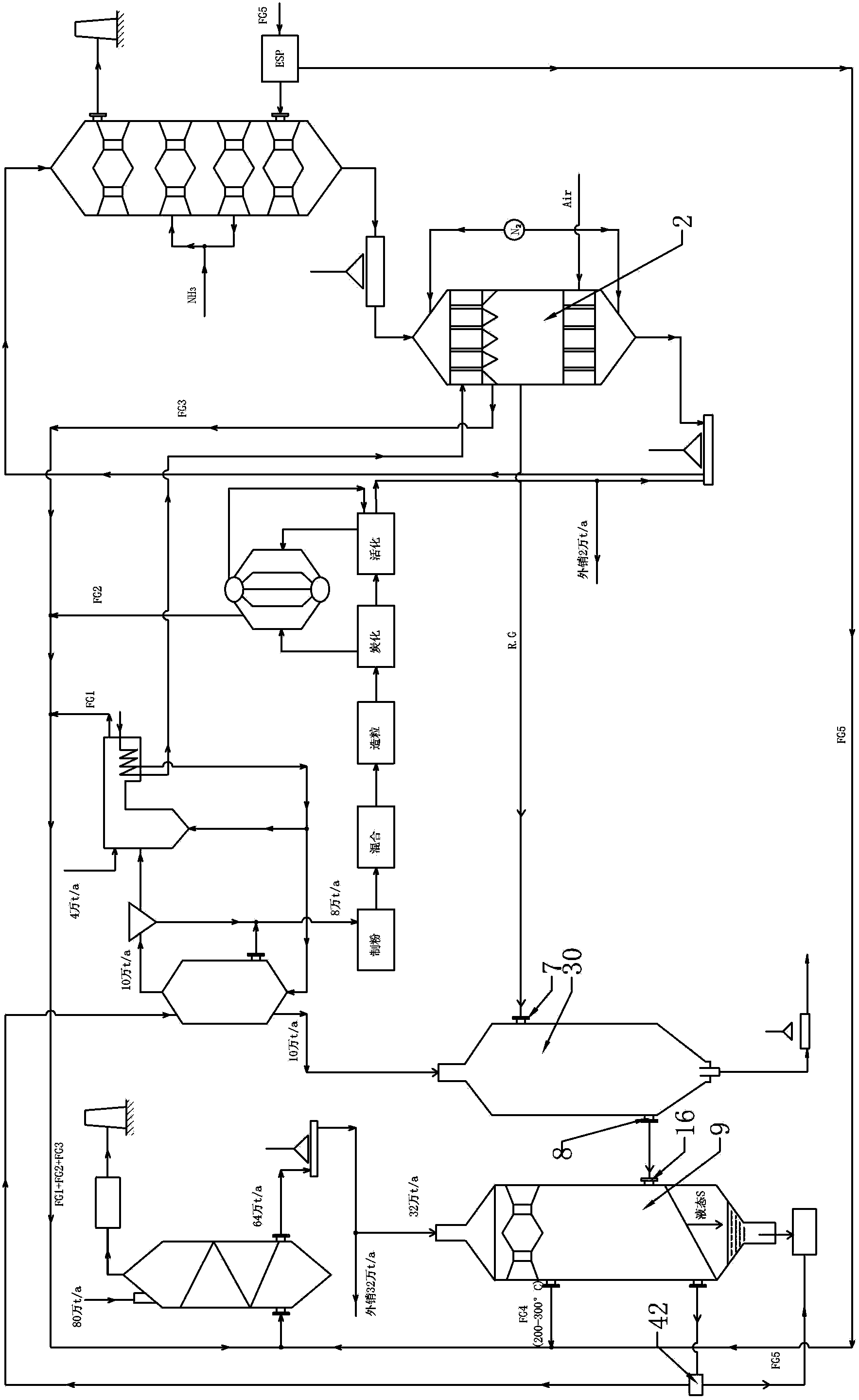

[0032] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the elemental sulfur reaction device is a moving bed reactor 30, the first gas inlet 7 is located at the upper part of the moving bed reactor 30, and the first gas outlet 8 is located at the moving bed reactor 30. In the lower part of the reactor 30 , the first gas outlet 8 communicates with the second gas inlet 16 of the second fixed-bed reactor 9 , and the first gas inlet 7 communicates with the gas outlet of the desorption tower 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com