Production process of multienzyme pieces

A production process and technology of multi-enzyme tablets, applied in the field of medicine, can solve problems such as inability to guarantee product quality, achieve ideal results and reduce the effect of increasing the amount of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

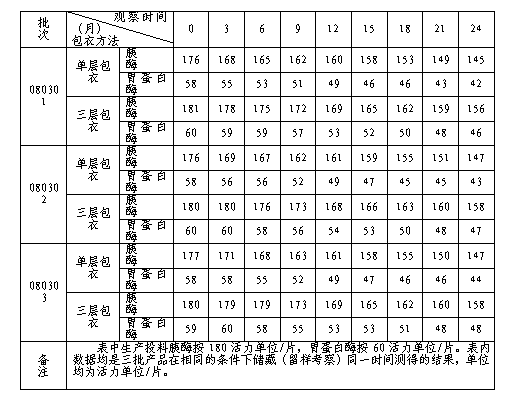

Examples

Embodiment 1

[0018] a. Remove the outer packaging of raw and auxiliary materials: Weigh 41.25kg of pancreatin, 5.50kg of pepsin, 18.50kg of sucrose, grind through a 100-mesh sieve, 40.00kg of sucrose, 1.10kg of dextrin, 0.40kg of magnesium stearate, 120.70kg of talcum powder, 0.10kg gelatin, 2.25kg polyacrylic resin, 20.00kg ethanol, 8.50kg starch, 0.75 bottle of diethyl phthalate, 0.75 bottle of Tween-80, 0.15 bottle of castor oil, 0.20 kg of carmine, 0.01 kg of red cabbage , rice core wax 0.10 kg, use 75% ethanol to disinfect the surface of the inner bag for later use;

[0019] b. Buffer;

[0020] c. Crushing and pretreatment of raw and auxiliary materials;

[0021] d. Weighing, batching and mixing;

[0022] e. Granulation, drying, granulation, and total blending;

[0023] f, granule transfer, tablet compression, substrate outer coating pressed after pancreatin and blank granules are mixed, when the polyacrylate layer is separated between pancreatin and pepsin, the original amount of ...

Embodiment 2

[0026] a. Remove the outer packaging of raw and auxiliary materials: Weigh 41.25kg of pancreatin, 5.50kg of pepsin, 18.50kg of sucrose, grind through a 100-mesh sieve, 40.00kg of sucrose, 1.10kg of dextrin, 0.40kg of magnesium stearate, 120.70kg of talcum powder, 0.10kg gelatin, 2.25kg polyacrylic resin, 20.00kg ethanol, 8.50kg starch, 0.75 bottle of diethyl phthalate, 0.75 bottle of Tween-80, 0.15 bottle of castor oil, 0.20 kg of carmine, 0.01 kg of red cabbage , rice core wax 0.10 kg, use 75% ethanol to disinfect the surface of the inner bag for later use;

[0027] b. Buffer;

[0028] c. Crushing and pretreatment of raw and auxiliary materials;

[0029] d. Weighing, batching and mixing;

[0030] e. Granulation, drying, granulation, and total blending;

[0031] f, granule transfer, tablet compression, substrate outer coating pressed after pancreatin and blank granules are mixed, when the polyacrylate layer is separated between pancreatin and pepsin, the original amount of ...

Embodiment 3

[0034] a. Remove the outer packaging of raw and auxiliary materials: Weigh 41.25kg of pancreatin, 5.50kg of pepsin, 18.50kg of sucrose, grind through a 100-mesh sieve, 40.00kg of sucrose, 1.10kg of dextrin, 0.40kg of magnesium stearate, 120.70kg of talcum powder, 0.10kg gelatin, 2.25kg polyacrylic resin, 20.00kg ethanol, 8.50kg starch, 0.75 bottle of diethyl phthalate, 0.75 bottle of Tween-80, 0.15 bottle of castor oil, 0.20 kg of carmine, 0.01 kg of red cabbage , rice core wax 0.10 kg, use 75% ethanol to disinfect the surface of the inner bag for later use;

[0035] b. Buffer;

[0036] c. Crushing and pretreatment of raw and auxiliary materials;

[0037] d. Weighing, batching and mixing;

[0038] e. Granulation, drying, granulation, and total blending;

[0039] f, granule transfer, tabletting, substrate outer coating pressed after pancreatin and blank granules are mixed, when the polyacrylate layer is separated between pancreatin and pepsin, the original amount of polyacr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com