Forming agent for hard alloy production

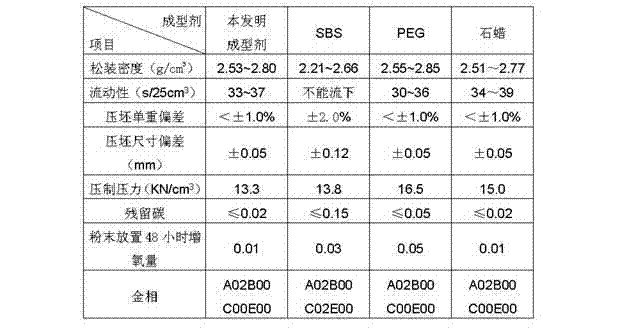

A technology of cemented carbide and forming agent, which is applied in the field of forming agent for cemented carbide production, and can solve problems such as poor fluidity, difficult quality control, troublesome preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: be 16.5% polyisobutylene, 83.5% 120 by mass percent # Dissolve gasoline, put them into a blender together, stir and mix, wait until polyisobutene is dissolved in gasoline, and form a uniform solution, that is, the molding agent of the present invention is obtained. Add it into the mixture or wet mill, and make cemented carbide products through drying, pressing, sintering and other processes (the process steps after the molding agent is prepared are the same as in the following examples). This formulation molding agent is suitable for the production of all cemented carbides.

Embodiment 2

[0013] Embodiment 2: be 20% polyisobutylene, 80% 120 by mass percent # Dissolve gasoline, put them into a blender together, stir and mix, and wait until polyisobutene dissolves in gasoline to form a uniform solution to obtain the molding agent of the present invention. This formula molding agent is suitable for the production of hard-to-form hard alloys with fine particles or complex shapes.

Embodiment 3

[0014] Embodiment 3: be 16.5% polyisobutylene, 10% paraffin, 73.5% 120 # Dissolve gasoline, put them into a blender together, stir and mix, and wait until polyisobutene dissolves in gasoline to form a uniform solution to obtain the molding agent of the present invention. This formula is suitable for the production of cemented carbide products that are prone to chipping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com