Method for improving high silicon steel preparation process capability by utilizing high-energy electric pulse

A technology of processing capacity and electric pulse, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problems of difficult processing, difficulty in forming large-scale production, and room temperature plasticity problems have not been effectively solved, so as to reduce the strength , Eliminate work hardening, omit the effect of intermediate annealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] For a high-silicon steel plate with a silicon content of 4% and no boron, the thickness is 2mm, and the tensile rate is 1s -1 . High-energy electrical pulses are applied during deformation. Electric pulse parameters are: frequency 300Hz, pulse width 150μs, peak current density 400A mm -2 , During the deformation process, the temperature of the material increases significantly, the stress decreases significantly, and the deformation is easier to carry out.

Embodiment 2

[0020] For a high-silicon steel sheet with a silicon content of 5% and a boron content of 150ppm, the thickness is 1mm, and the tensile rate is 10 -1 the s -1 , applying high-energy electric pulses during deformation. Electric pulse parameters are: frequency 200Hz, pulse width 100μs, peak current density 280A mm -2 , During the deformation process, the temperature of the material increases significantly, the stress decreases significantly, and the deformation is easier to carry out.

Embodiment 3

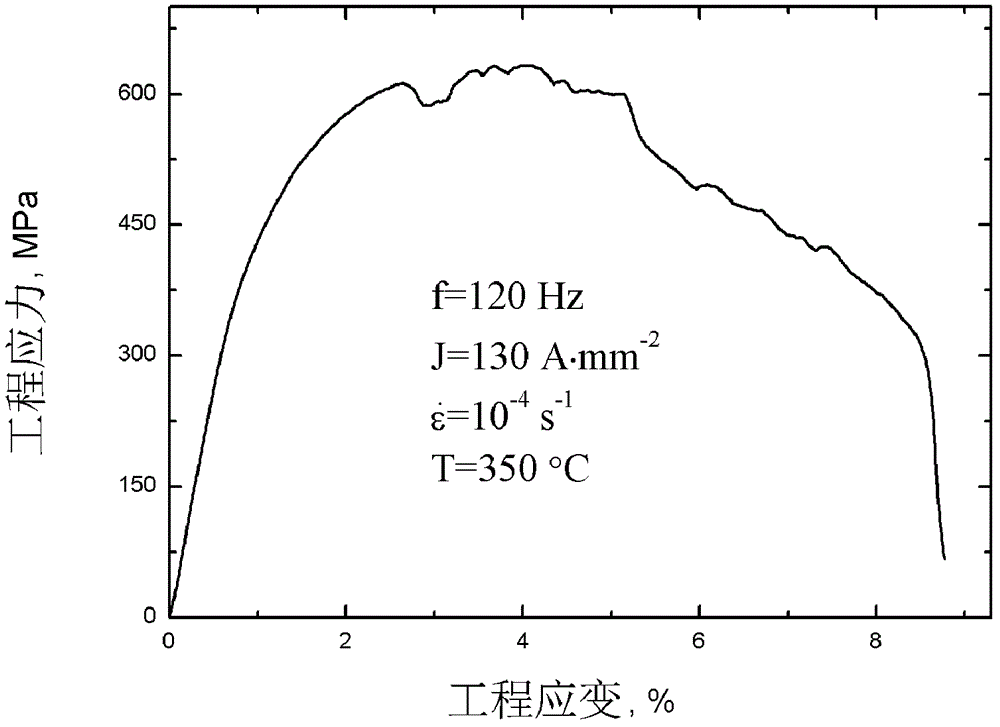

[0022] For a high-silicon steel sheet with a silicon content of 6.5% and a boron content of 150ppm, the thickness is 0.3mm, and the tensile rate is 10 -4 the s -1 , applying high-energy electric pulses during deformation. Electric pulse parameters are: frequency 120Hz, pulse width 70μs, peak current density 130A mm -2 , During the deformation process, the temperature of the material rises to 350°C, the flow stress remains below 600Mpa, and the stress decreases significantly, such as figure 2 As shown, the deformation is easier to carry out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com