Hartmann wavefront sensor based on diffraction grating arrays

A diffraction grating and sensor technology, applied in the field of optical detection, achieves the effect of stable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

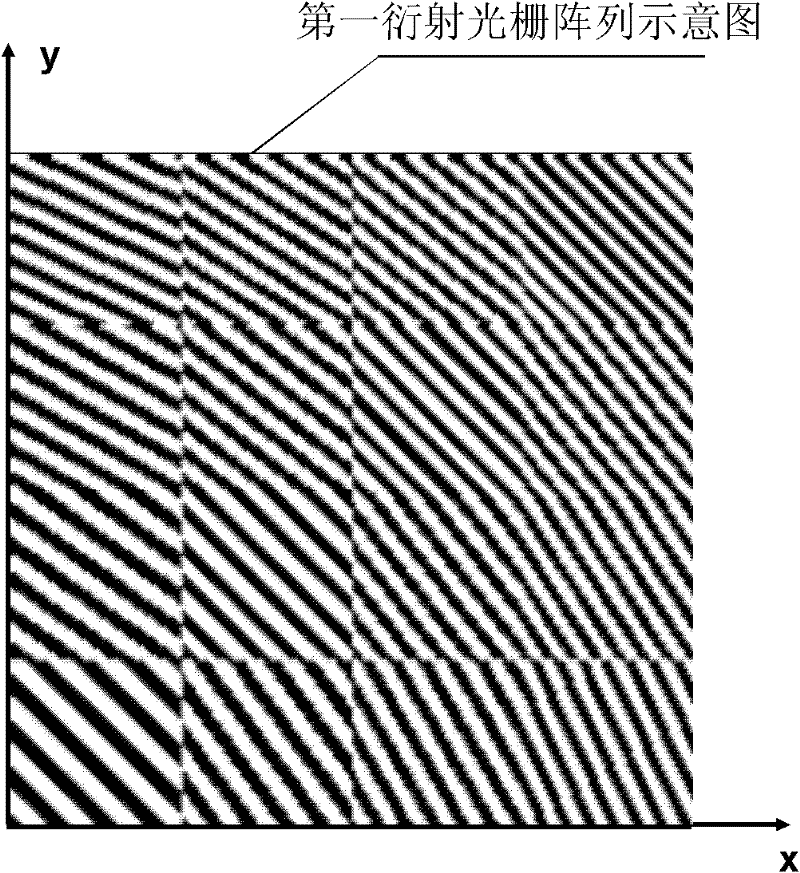

[0033] In this example, the variable spatial frequency sub-grating structure of the first diffraction grating array 3 and the second diffraction grating array 6 adopts a liquid crystal spatial light modulator with electrical addressing pure phase modulation, and the optical matching system 1 adopts a magnification factor of 5 In the telescope system, the beam splitter 2 uses a plate beam splitter with a transmittance ratio of 5:5. In order to eliminate the additional wavefront distortion introduced by the Fourier lens, the first Fourier lens 4 and the second Fourier lens 7 both use an aberration-ablation lens with a focal length of 100 mm. , CCD1 detector 5 and CCD2 detector 8 are both MVC-II1M area array CCD photodetectors with a pixel size of 1024×1280.

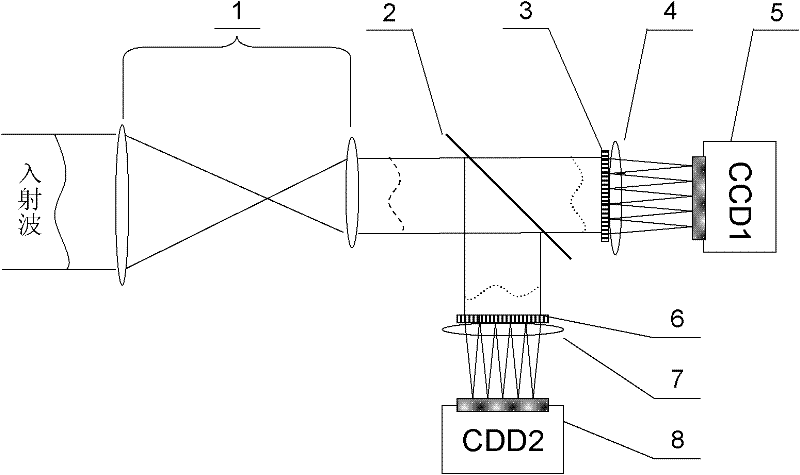

[0034] Such as figure 1 As shown, the Hartmann wavefront sensor based on the diffraction grating array of the present invention includes an optical matching system 1 and a beam splitter 2 behind it, and the transmission sur...

Embodiment 2

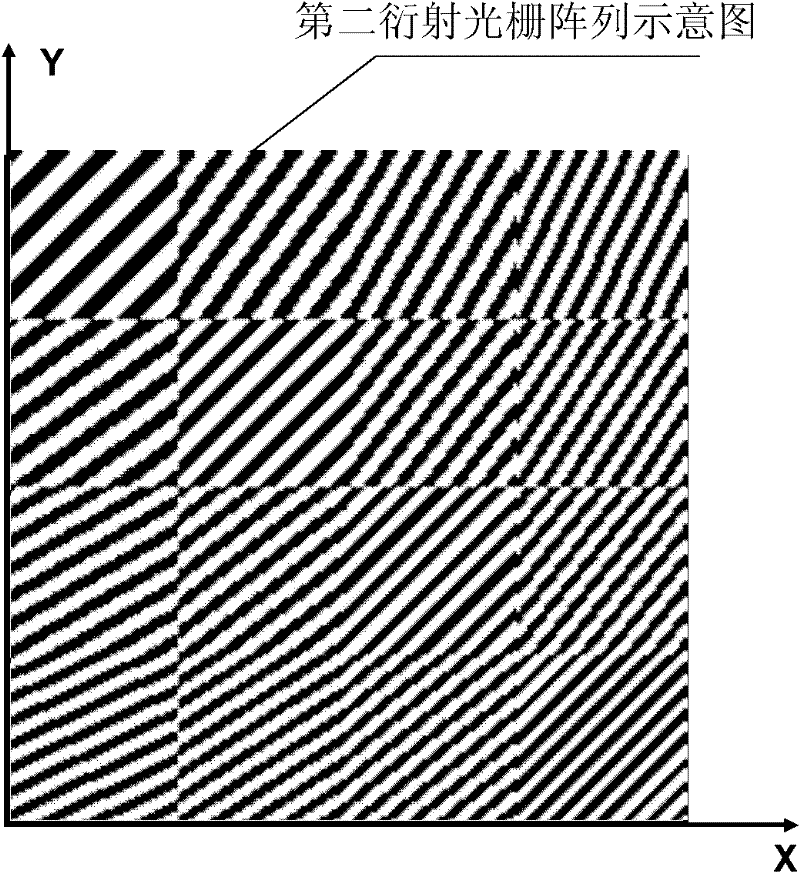

[0051] In this example, the variable spatial frequency sub-grating structure of the first diffraction grating array 3 and the second diffraction grating array 6 adopts a liquid crystal spatial light modulator with electrical addressing amplitude modulation, and the optical matching system 1 adopts a multiplier of 5. The adjusted telescope system, the beam splitter 2 adopts a beam splitting prism with a splitting ratio of 5:5, in order to eliminate the additional wavefront distortion introduced by the Fourier lens, the first Fourier lens 4 and the second Fourier lens 7 both use aberration aberration with a focal length of 100mm The lens, CCD1 detector 5 and CCD2 detector 8 all adopt the area array CCD photodetector of model MVC-II1M with a pixel size of 1024×1280.

[0052] Such as Image 6 As shown, the present invention is based on the Hartmann wavefront sensor of the diffraction grating array, including the optical matching system 1 and the beam splitter 2 behind it, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com