Conducting formulation

A preparation and conductive additive technology, applied in the field of OLED devices, can solve the problems of OLED device performance deterioration, impossible conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0112] The present invention will be described in more detail below with reference to the following examples, which are only illustrative and do not limit the scope of the present invention.

Embodiment 1

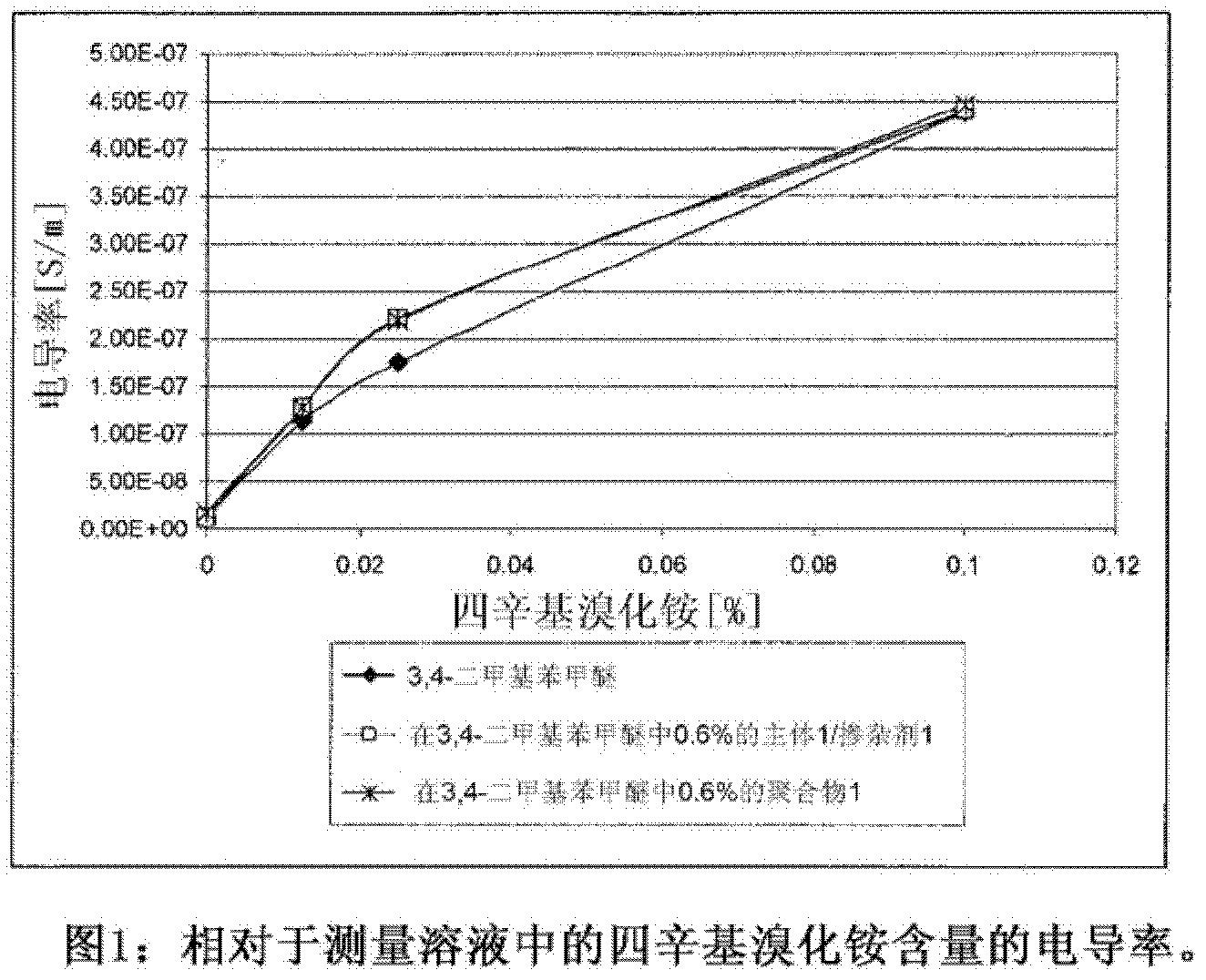

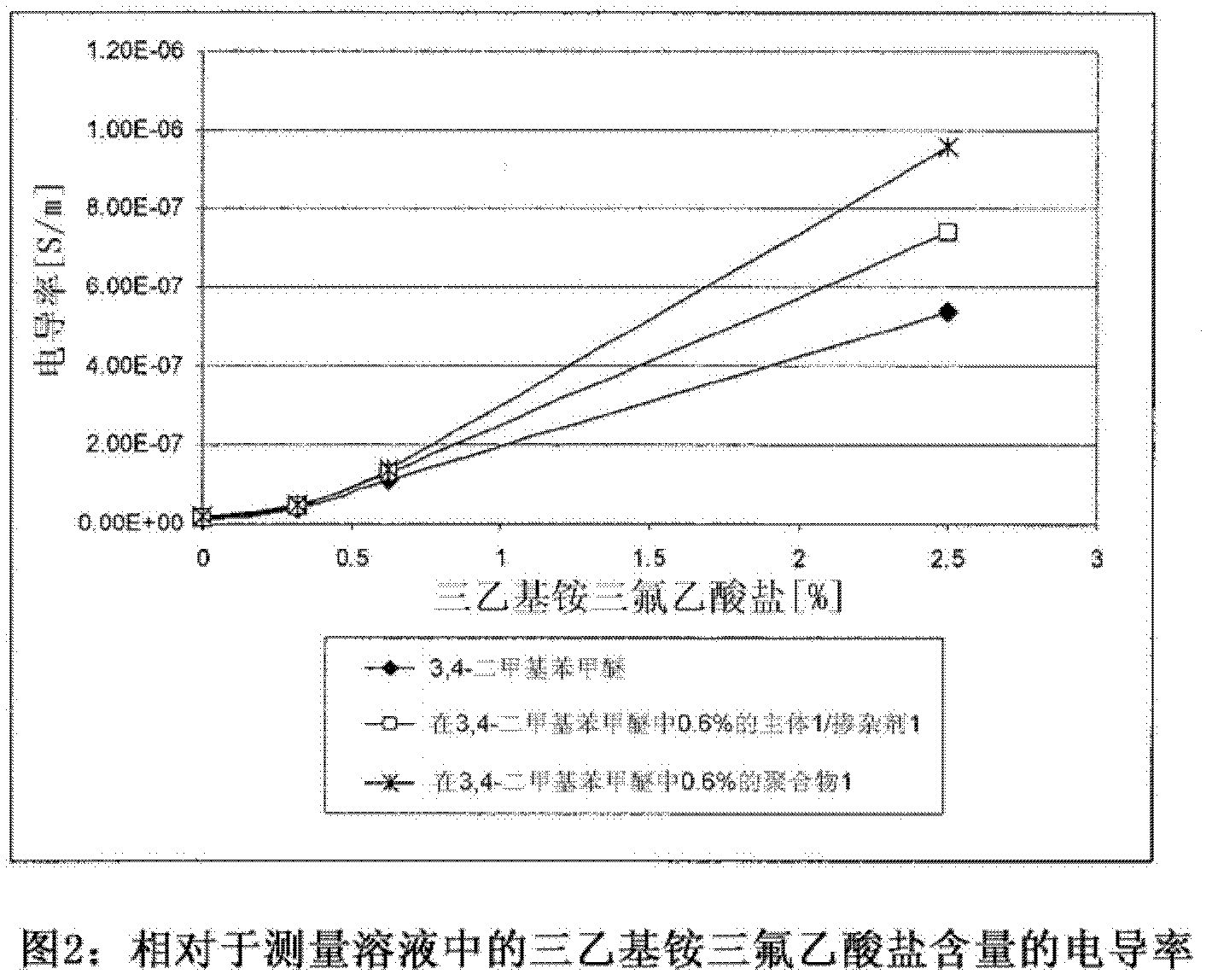

[0125] Measure electrical resistance and calculate conductivity for: o-xylene, tetraoctylammonium bromide in o-xylene, tributylammonium trifluoroacetate in o-xylene, 3,4-dimethyl Anisole, tetraoctylammonium bromide in 3,4-dimethylanisole, and triethylammonium trifluoroacetate in 3,4-dimethylanisole. The results are shown in Table 1 and expressed as a function of concentration in figure 1 with 2 middle.

[0126] Table 1

[0127]

[0128]

[0129] Samples containing conductive additives had higher conductivity than corresponding control samples without conductive additives.

Embodiment 2

[0131]

[0132] Polymer 1

[0133] 0.6 part of Polymer 1 (see Example 6 in EP 1741148) was dissolved in 99.4 parts of 3,4-dimethylanisole (0.6% of Polymer 1 in 3,4-dimethylanisole) .

[0134] The electrical resistance was measured and the conductivity calculated as described in Example 1 for: Polymer 1 solution, Tetraoctylammonium bromide in Polymer 1 solution and Triethylammonium trifluoride in Polymer 1 solution Acetate. The results are shown in Table 2 and are shown as a function of concentration in figure 1 with 2 middle.

[0135] Table 2

[0136]

[0137] Samples containing conductive additives had higher conductivity than corresponding control samples without conductive additives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com