Face gear grinding method based on worm grinding wheel

A technology of worm grinding wheel and processing method, which is applied in the direction of metal processing equipment, manufacturing tools, and parts of grinding machine tools, etc., and can solve the problems of poor transmission performance and low machining accuracy of face gears, etc.

Inactive Publication Date: 2012-04-25

唐进元

View PDF6 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem solved by this patent is: Aiming at the defects of low machining precision and poor transmission performance of gears in the market, a face gear grinding processing method is invented

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

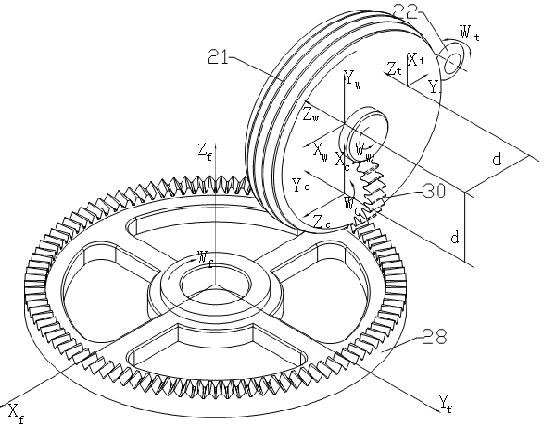

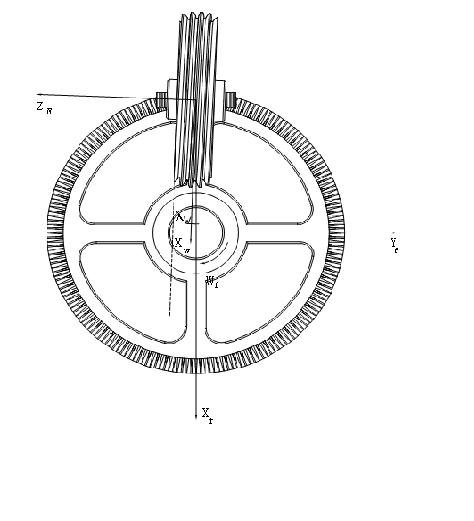

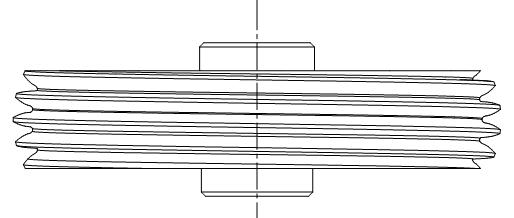

The invention provides a face gear grinding method based on a worm grinding wheel. A face gear 28, the worm grinding wheel 21, a straight gear 30 and a grinding wheel 22 for finishing a worm are adopted in the method. The face gear grinding method is characterized in that during the machining process, the face gear 28 rotates around Z-f at a constant rotating speed Wf, the worm grinding wheel 21 rotates around Zw at a constant rotating speed Ww, the straight gear 30 rotates around a Zc axis at a constant rotating speed Wc, and the grinding wheel 22 rotates around an Xt axis at a constant rotating speed Wt. During the rotation process, the tooth surface of the worm grinding wheel can be used for grinding off the tooth surface of the face gear contacted with the tooth surface so as to reach the effect of grinding the face gear; and meanwhile the worm grinding wheel 21 performs linear feed movement along the direction of the tooth width Xf of the face gear until the whole tooth profile of the face gear is completely machined. The face gear grinding method based on the worm grinding wheel provided by the invention has the beneficial effects of realizing high-precision generation of the tooth surface of the face gear, reaching the effect of high-precision machining of the face gear, and improving the comprehensive transmission performance of the face gear.

Description

technical field [0001] The invention belongs to the field of face gear numerical control milling and gear grinding in the gear manufacturing method. Background technique [0002] Face gear transmission refers to the meshing of cylindrical gear and bevel gear to realize the transmission between spatially intersecting or interlaced axes. Compared with bevel gears, face gear transmission has the advantages of large coincidence, strong bearing capacity, strong stability, small vibration, and small space occupation. With the development of aerospace industry, face gear transmission has been widely used in the power plant of aircraft and occupies a very important position. [0003] Face gear processing method is one of the main tasks of face gear research. In recent years, scholars at home and abroad have done a lot of research on it. Due to the poor bearing capacity, the application of face gears can only stay in low-speed and light-load situations, which cannot meet the transm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23F5/04B24B53/075

Inventor 唐进元尹凤雷敦财邸栓虎

Owner 唐进元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com