Fluorine-containing sulfuric acid separation concentration device and separation concentration method

A technology for concentration device and sulfuric acid, applied in sulfur trioxide/sulfuric acid and other directions, can solve the problems of difficult realization, complicated operation steps, strong corrosiveness, etc., and achieve the effect of simple method, good separation and concentration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

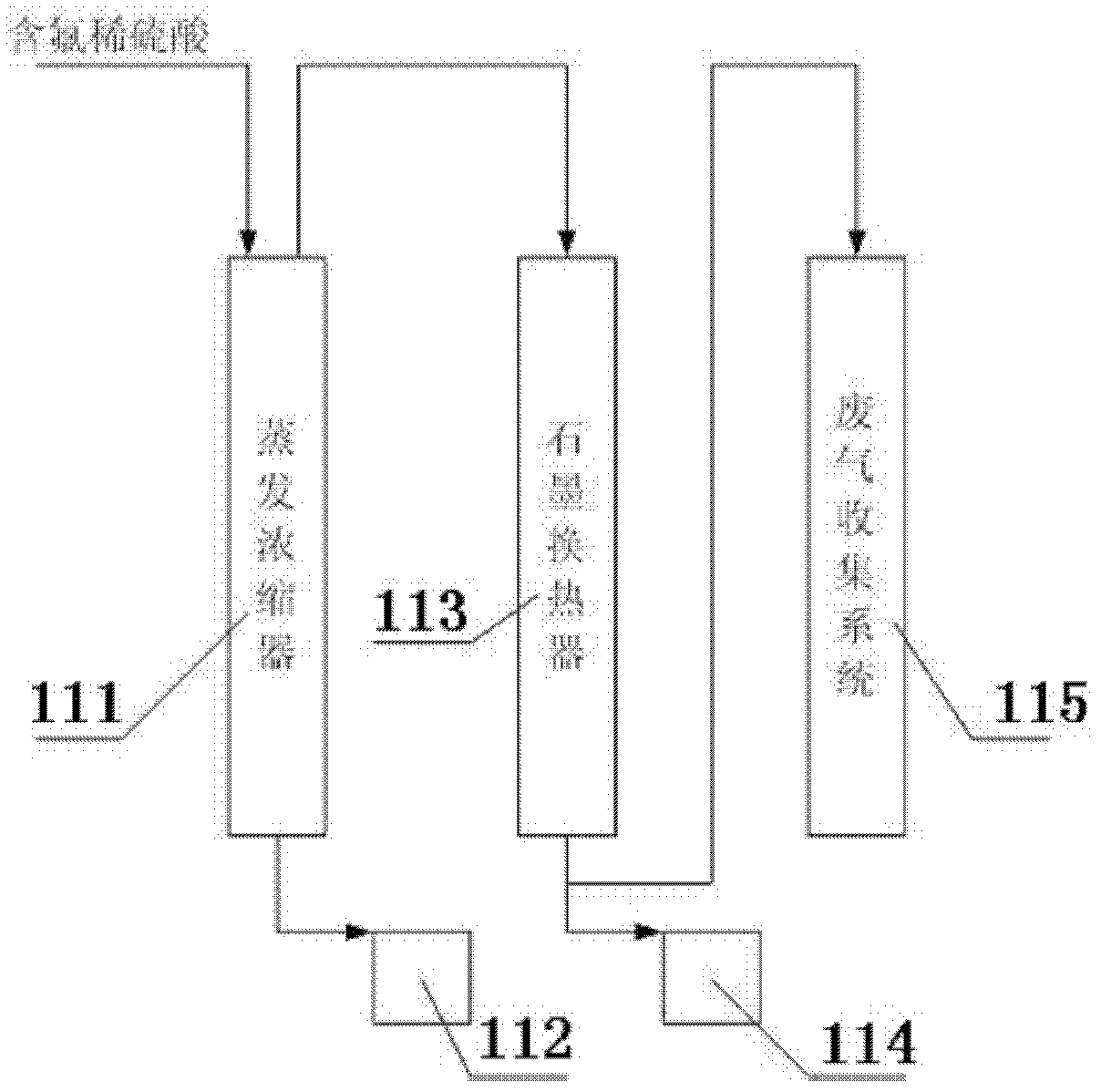

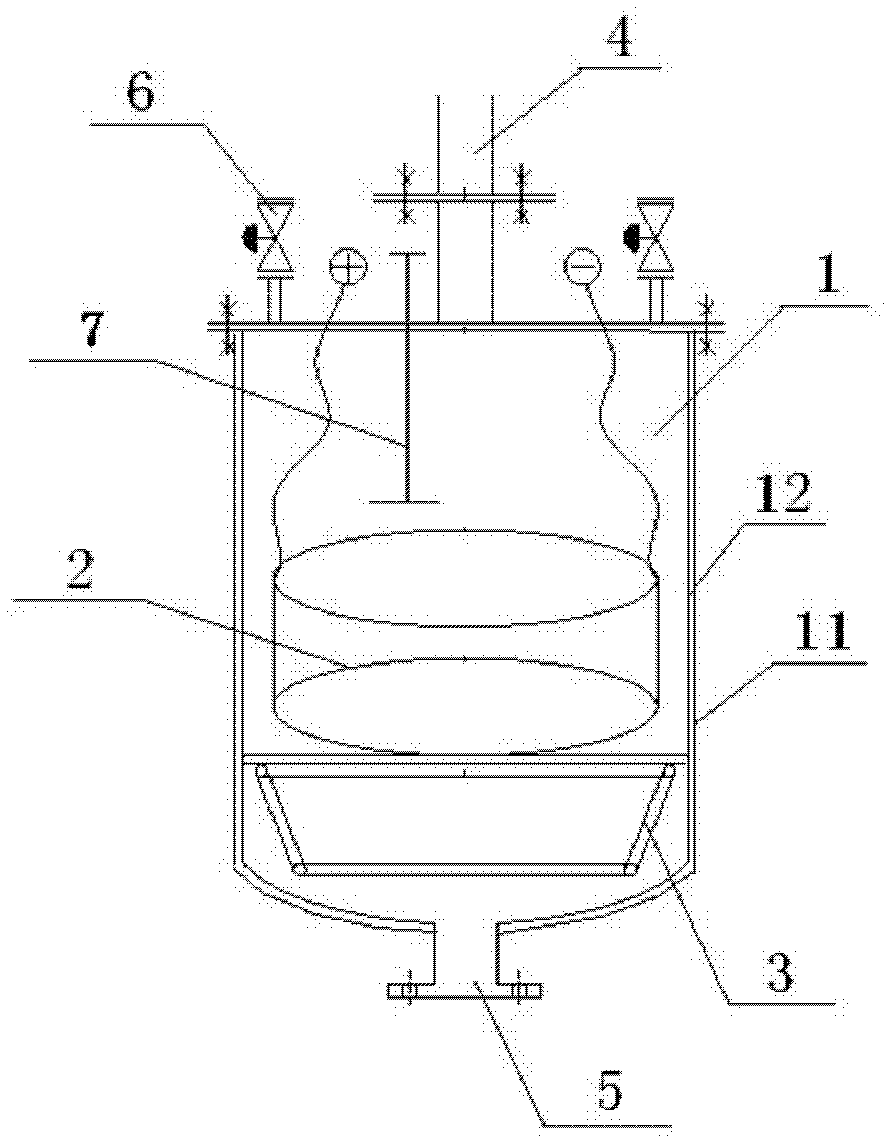

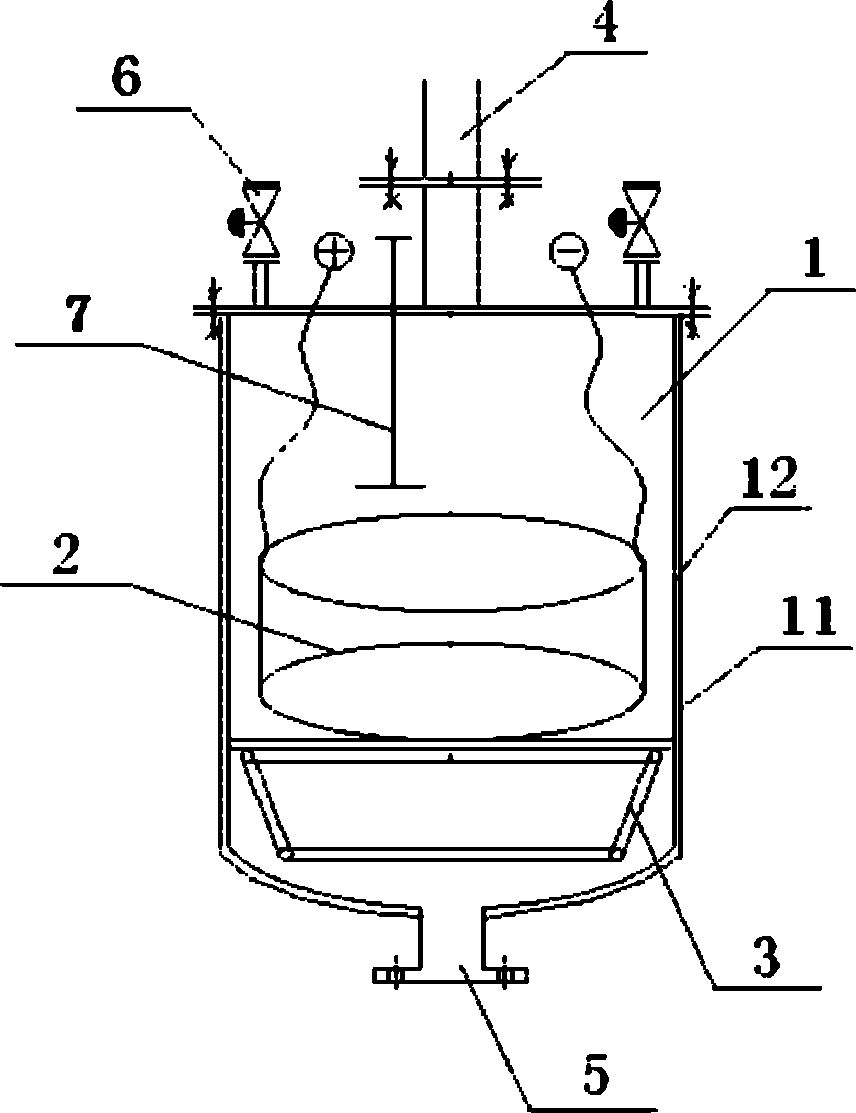

[0079] Taking sulfuric acid containing hydrofluoric acid as the raw material liquid, wherein the sulfuric acid is 77.01wt%, the hydrogen fluoride is 12.38wt%, and the water is 10.61wt%; the raw material liquid is placed in figure 1In the concentration device in the separation and concentration device shown, heat to 110°C under the conditions of 10r / min and -50Pa, and heat for 10h to obtain concentrated sulfuric acid and mixed gas; use 8°C chilled water to cool the mixed gas to obtain hydrogen Fluoric acid;

[0080] Carry out component analysis to described concentrated sulfuric acid, the result shows, wherein, sulfuric acid is 90.08wt%, hydrofluoric acid is 0.57wt%, water is 9.35wt%; Carry out component analysis to described hydrofluoric acid, result shows, sulfuric acid is 1.82 wt%, hydrofluoric acid is 81.84wt%, and water is 16.34wt%.

[0081] It can be seen from Example 1 that when the raw material solution is heated to 110° C. under a slight negative pressure of -50 Pa, t...

Embodiment 2

[0083] Taking sulfuric acid containing hydrofluoric acid as the raw material liquid, wherein the sulfuric acid is 76.92wt%, the hydrogen fluoride is 14.53wt%, and the water is 8.55wt%; the raw material liquid is placed in figure 1 In the concentration device in the separation and concentration device shown, heat to 125°C under the conditions of 10r / min and -100Pa, and heat for 15h to obtain concentrated sulfuric acid and mixed gas; use 8°C chilled water to cool the mixed gas to obtain hydrogen Fluoric acid;

[0084] Carry out component analysis to described concentrated sulfuric acid, the result shows, wherein, sulfuric acid is 90.59wt%, hydrofluoric acid is 0.37wt%, water is 9.14wt%; Carry out component analysis to described hydrofluoric acid, result shows, sulfuric acid is 1.86 %, hydrofluoric acid 80.12%, water 17.01%.

[0085] It can be seen from Example 1 that when the raw material solution is heated to 125° C. under a slight negative pressure of -100 Pa, the separation ...

Embodiment 3

[0087] Taking sulfuric acid containing hydrofluoric acid as the raw material liquid, wherein the sulfuric acid is 77.01wt%, the hydrogen fluoride is 12.38wt%, and the water is 10.61wt%; the raw material liquid is placed in figure 1 In the concentration device in the separation and concentration device shown, heat to 120°C under the conditions of 10r / min and -50Pa, and heat for 15h to obtain concentrated sulfuric acid and mixed gas; use 8°C chilled water to cool the mixed gas to obtain hydrogen Fluoric acid;

[0088] Carry out component analysis to described concentrated sulfuric acid, result shows, wherein, sulfuric acid is 92.08wt%, hydrofluoric acid is 0.41wt%, water is 7.51wt%; Carry out component analysis to described hydrofluoric acid, result shows, sulfuric acid is 1.91wt%. wt%, hydrofluoric acid is 74.67wt%, and water is 23.42wt%.

[0089] It can be seen from Example 3 that when the raw material solution is heated to 120° C. under a slight negative pressure of -50 Pa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com