Biological enzyme liquid/beverage multistage ultrafiltering-purifying-separating-concentrating device

A purification, separation and concentration device technology, which is applied in the biological field, can solve the problems of high cost and poor practicability, and achieve the effects of increasing product yield, reducing enzyme activity loss, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

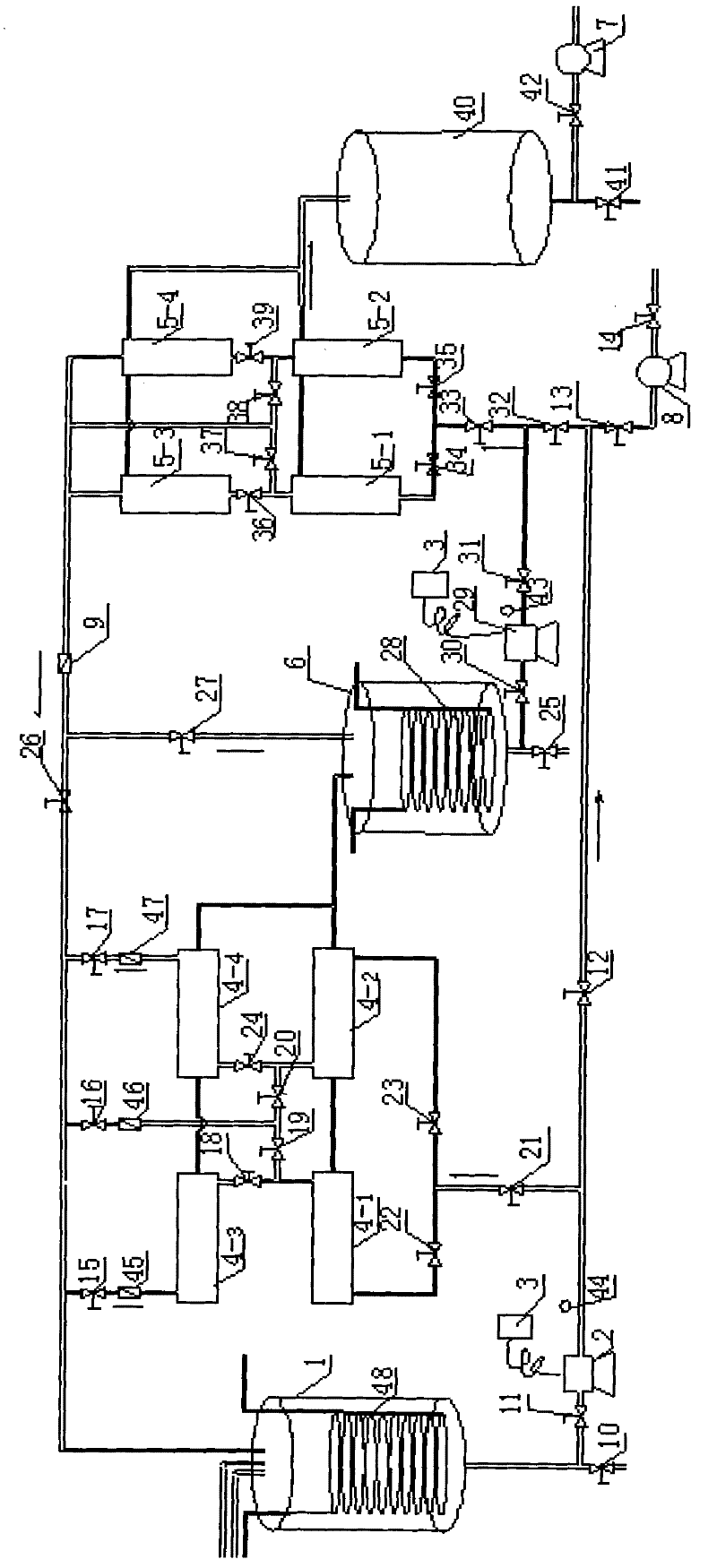

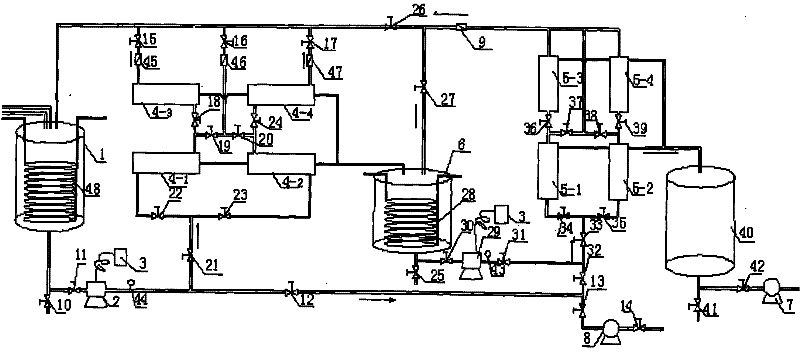

[0037] Connect the raw material storage tank (1) and the cam pump (2) through a plastic or stainless steel feed pipe, and set a valve (11) between the two, and the cam pump and the plate ultrafiltration (4-1, 4-2) are fed through plastic The feeding pipe is connected, and valves (21)(22)(23) are set between the two, and a pressure gauge is installed on the feeding pipe, and the pressure gauge seat is bonded with epoxy resin glue, and the pressure gauge is connected to the table seat with threads; the cam The pumps (2), (29) adjust the flow through the flow regulating device (3) installed on the electric control cabinet; the return flow on the plate ultrafilter (4-1, 4-2, 4-3, 4-4) The outlet is connected to the raw material storage tank through flow meters (45)(46), (47), valves (15)(16)(17) through plastic or stainless steel pipes, and the other permeated water outlet is collected with filtrate through plastic or stainless steel pipes The tank (6) is connected; the filtrate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com