Bio-enzyme gel breaker and technique for water-based guargum fracturing gel breaking with the same

A gel breaker and biological enzyme technology, applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of incomplete gel breaking, long residence time, operation failure, etc. Effects of transportation, vigor loss, and formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

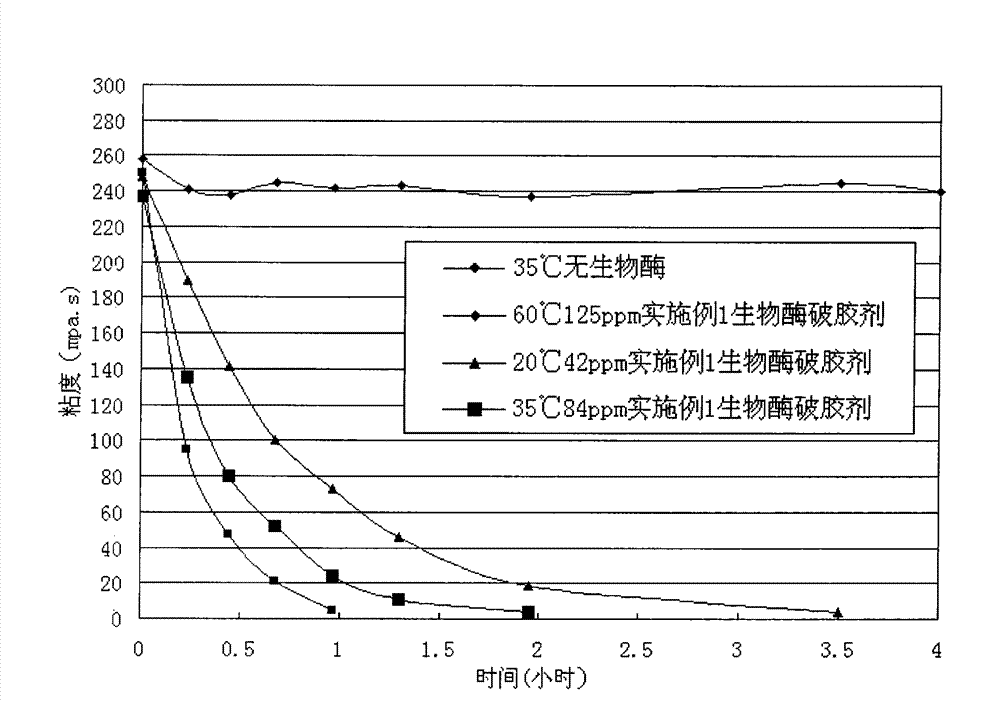

Embodiment 1

[0051] This bio-enzyme breaker is solid, and its weight percentage proportion selection range is β-mannanase 10-40%, cellulase 5-20%, pectinase 5-10%, (NH 4 ) 2 SO 4 3-8%, NaCl 2-5%, ZnCl 2 1.5-4%, persulfate 10-60%.

[0052] The best choice is that its weight ratio is 30% of β-mannanase, 10% of cellulase, 8% of pectinase, (NH 4 ) 2 SO 4 5%, NaCl 5%, ZnCl 2 2%, potassium persulfate 40%.

[0053] Embodiment 1 is to utilize this biological enzyme gel breaker to carry out the technological process of water-based guar gum fracturing fluid gel breaking. The processing steps are as follows:

[0054] 1) prepare concentration according to weight ratio and be 0.7% borax aqueous solution 5m 3 ;

[0055] 2) dissolving the biological enzyme in the borax aqueous solution prepared in step 1) to form a cross-linking liquid, wherein the concentration of the biological enzyme is 0.084%-0.25%;

[0056] 3) Prepare base liquid 100m by weight percentage 3 , wherein the concentration ...

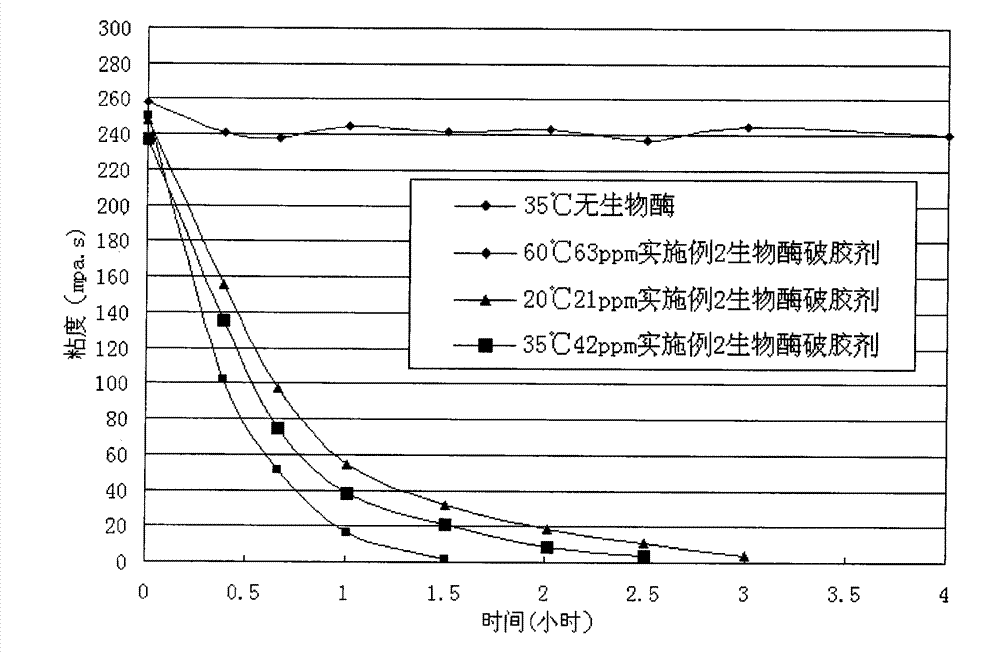

Embodiment 2

[0066] Its weight ratio of this biological enzyme gel breaker is, β-mannanase 15-50%, dextranase 5-15%, xanthan gumase 5-10%, (NH 4 ) 2 SO 4 3-10%, NaCl 2-5%, ZnCl 2 1.5-5%, ammonium persulfate 10-60%.

[0067] Its optimal weight ratio is 35% of β-mannanase, 8% of glucanase, 5% of xanthan gumase, (NH 4 ) 2 SO 4 5%, NaCl 5%, ZnCl 2 2%, sodium persulfate 40%.

[0068] Embodiment 2 is to utilize this biological enzyme gel breaker to carry out the technological process of water-based guar gum fracturing fluid gel breaking. The processing steps are as follows:

[0069] 1) According to the weight ratio, prepare a concentration of 0.4% borax aqueous solution 8m 3 ;

[0070] 2) Dissolving the biological enzyme gel breaker in the borax aqueous solution prepared in step 1) to form a cross-linking liquid, wherein the concentration of the biological enzyme gel breaker is 0.028%-0.11%;

[0071] 3) Prepare base liquid 100m by weight percentage 3 , wherein the guar gum concentr...

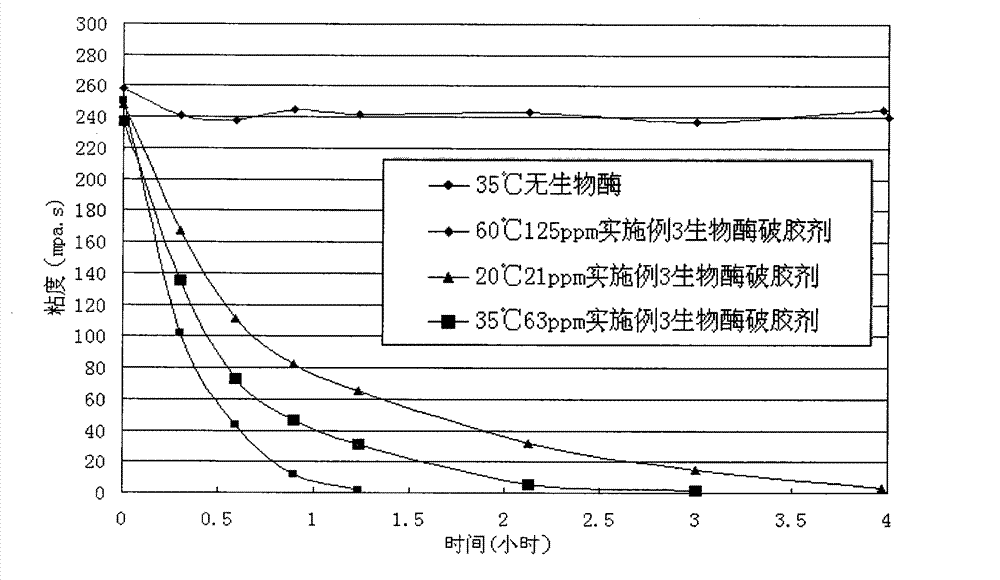

Embodiment 3

[0081] Its weight ratio of this biological enzyme gel breaker is, β-mannanase 15-50%, dextranase 5-15%, cellulase 5-20%, (NH 4 ) 2 SO 4 3-10%, NaCl 2-5%, ZnCl 2 1.5-5%, persulfate 10-60%.

[0082] Its optimal weight ratio is 35% of β-mannanase, 3% of glucanase, 10% of cellulase, (NH 4 ) 2 SO 4 7%, NaCl 5%, ZnCl 2 5%, persulfate 35%.

[0083] Embodiment 3 is to utilize this biological enzyme gel breaker to carry out the technological process of water-based guar gum fracturing fluid gel breaking. The processing steps are as follows:

[0084] 1) prepare concentration according to weight ratio and be 0.5% borax aqueous solution;

[0085] 2) dissolving the biological enzyme gel breaker in the borax aqueous solution prepared in step 1) to form a cross-linking liquid, wherein the concentration of the biological enzyme is 0.023%-0.138%;

[0086] 3) Prepare base liquid 100m by weight percentage 3 , wherein 0.25% or 0.5% of guar gum; 1.5% or 0.5% of potassium chloride; 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com