Treating system for industrial wastewater containing heavy metal and treating method thereof

A technology for industrial wastewater and treatment systems, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, complicated operation, low metal purity, etc., and achieve the ability to withstand stress The effect of capacity improvement, automation degree improvement and power consumption cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

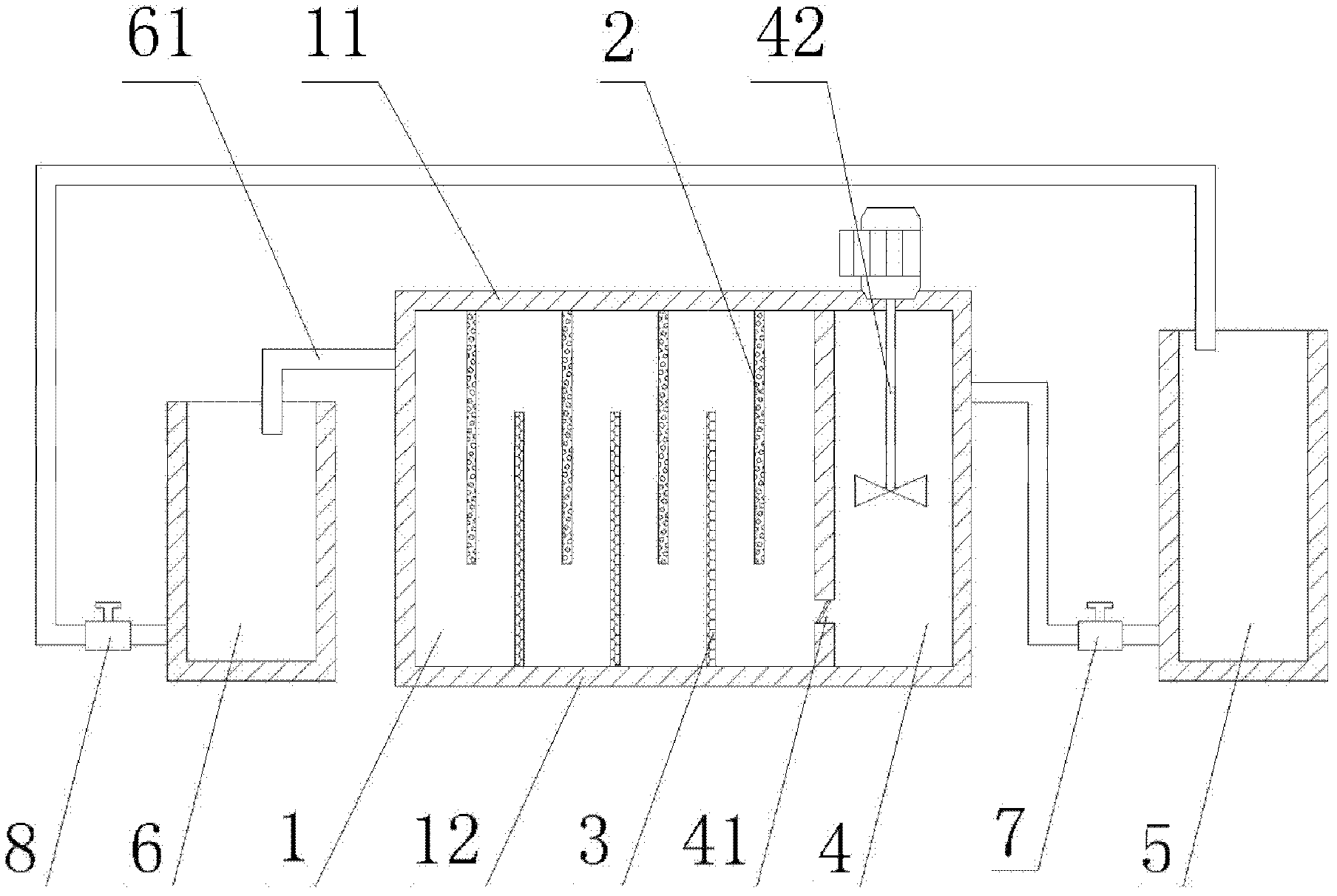

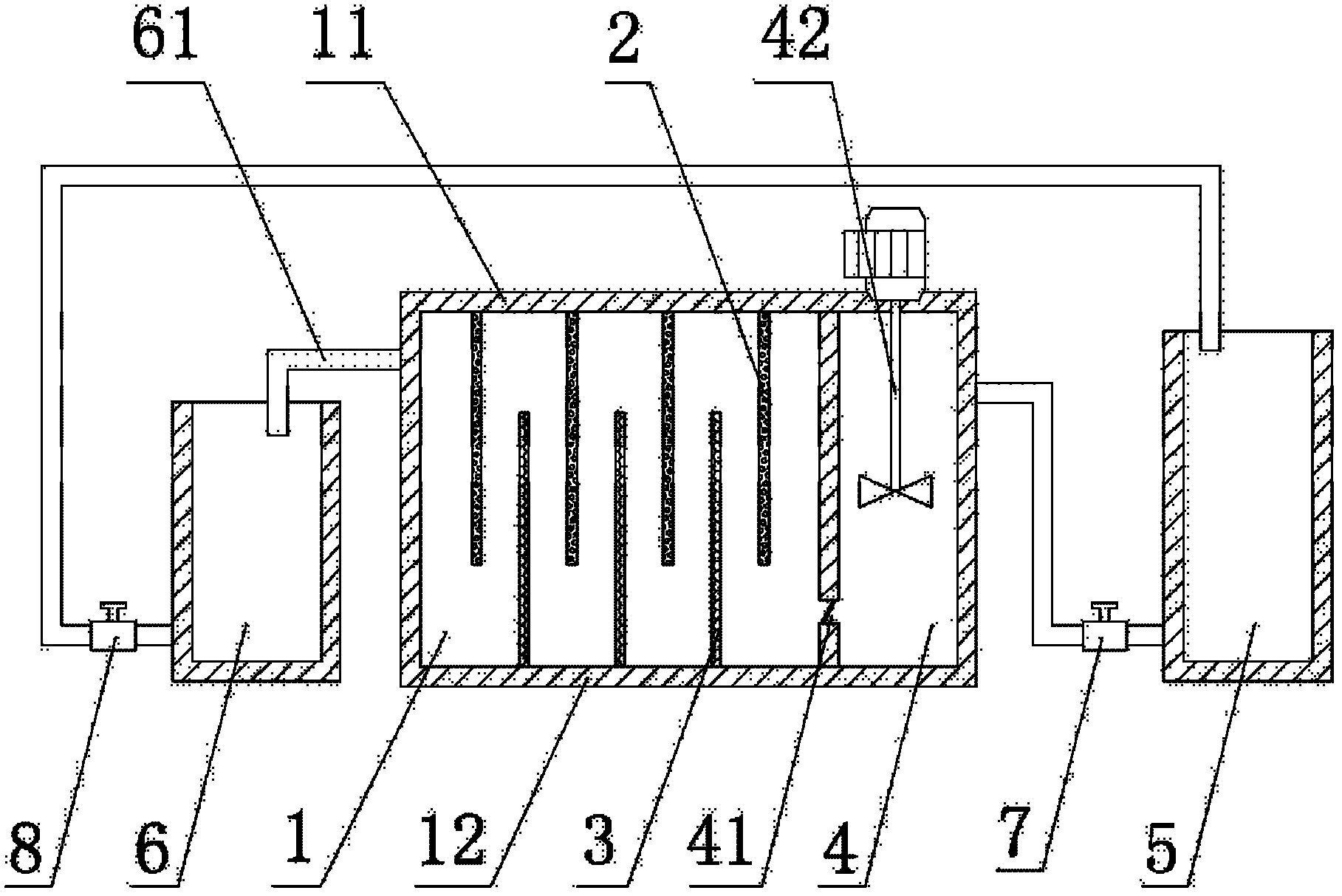

[0024] See figure 1 , A treatment system for industrial wastewater containing heavy metals, including: electrolytic tank 1, circulation tank 5 and transfer tank 6. One side of the electrolytic cell 1 is provided with a processing liquid mixing chamber 4, the processing liquid mixing chamber 4 is in communication with the electrolytic cell 1, and a connecting pipe 41 is provided between the processing liquid mixing chamber 4 and the electrolytic cell 1, and the connecting pipe 41 is provided with Valve, the solution to be treated enters the electrolytic cell 1 through the connecting pipe 41. A stirrer 42 is provided in the treatment liquid mixing chamber 4. When additives are added to the solution to be treated, the stirrer 42 is turned on so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com