Eccentric machining method for excircle of piston

A processing method and piston technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as poor flexibility of eccentric processing, poor dimensional stability of workpieces, complicated manufacturing tooling, etc., and achieve high practical value and convenient operation , The effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

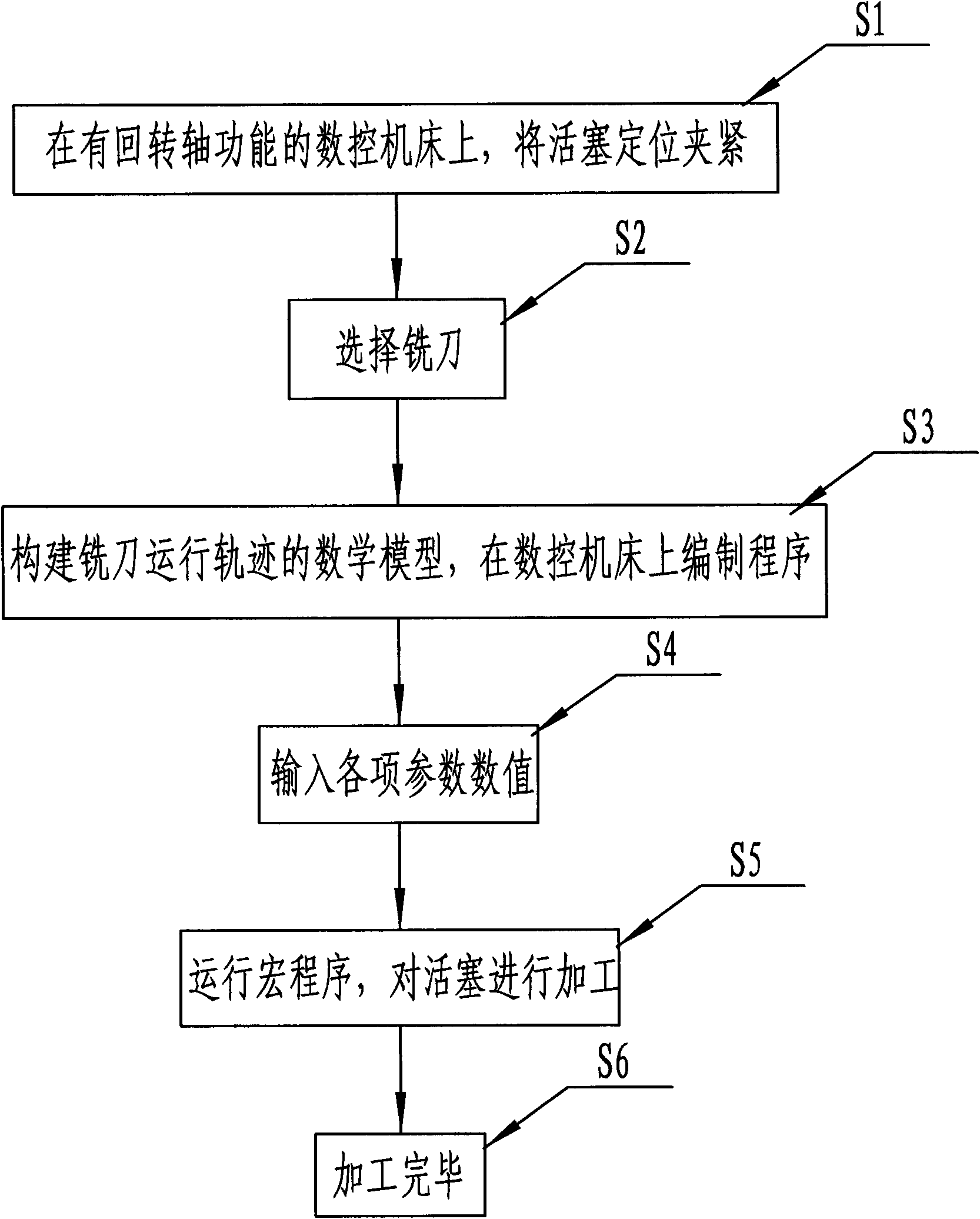

[0021] figure 1 It is a flow chart of the eccentric machining method of the piston outer circle of the present invention.

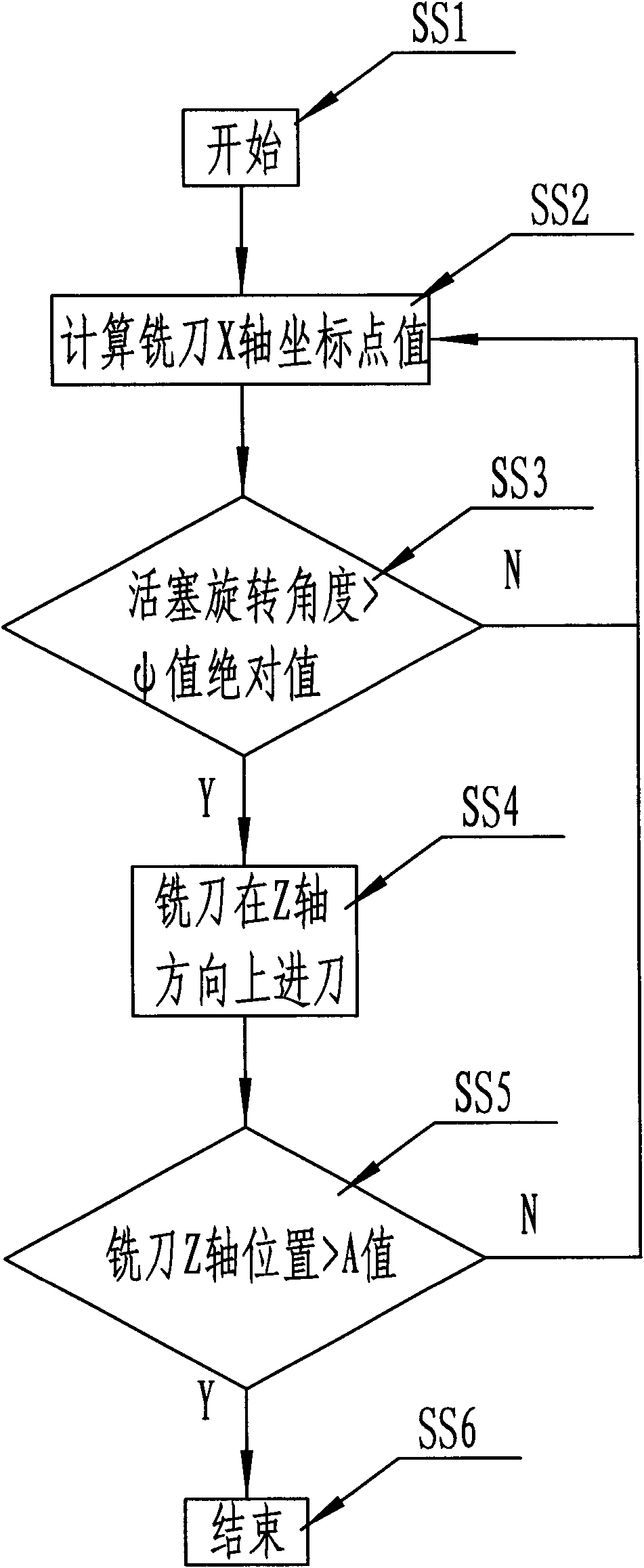

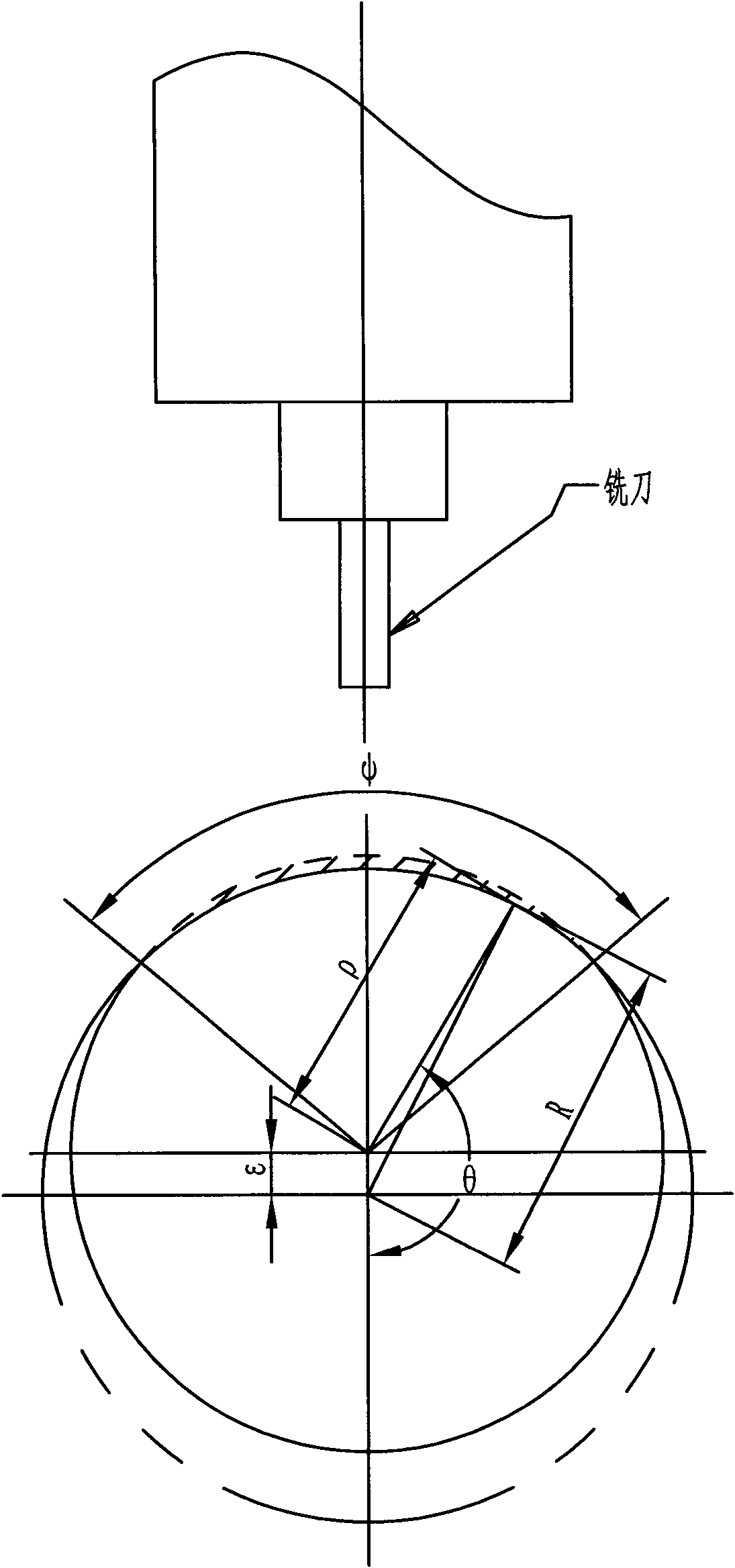

[0022] First of all, on the CNC machine tool with rotary axis function, the piston is positioned and tightened. Secondly, select the milling cutter according to the processing efficiency, the roughness of the processed surface, and the material of the processed material. Then construct the mathematical model of the milling cutter running track, where R represents the blank radius of the machining piston, ε represents the eccentricity, ρ represents the distance from the actual processing point of the milling cutter to the center of the circle, θ represents the angle between ε and ρ, and Create macro programs on the machine tool. Enter the original value of each parameter. Then run the macro program to process the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com