Bent conducting nozzle type twin-wire narrow-gap MIG/MAG (metal inert gas/metal active gas) welding torch

A contact tip, narrow gap technology, applied in arc welding equipment, electrode characteristics, welding equipment and other directions, can solve the problems of increased heat input, increased metal filling, increased welding workload, etc., to achieve high welding production efficiency, Stable and reliable performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

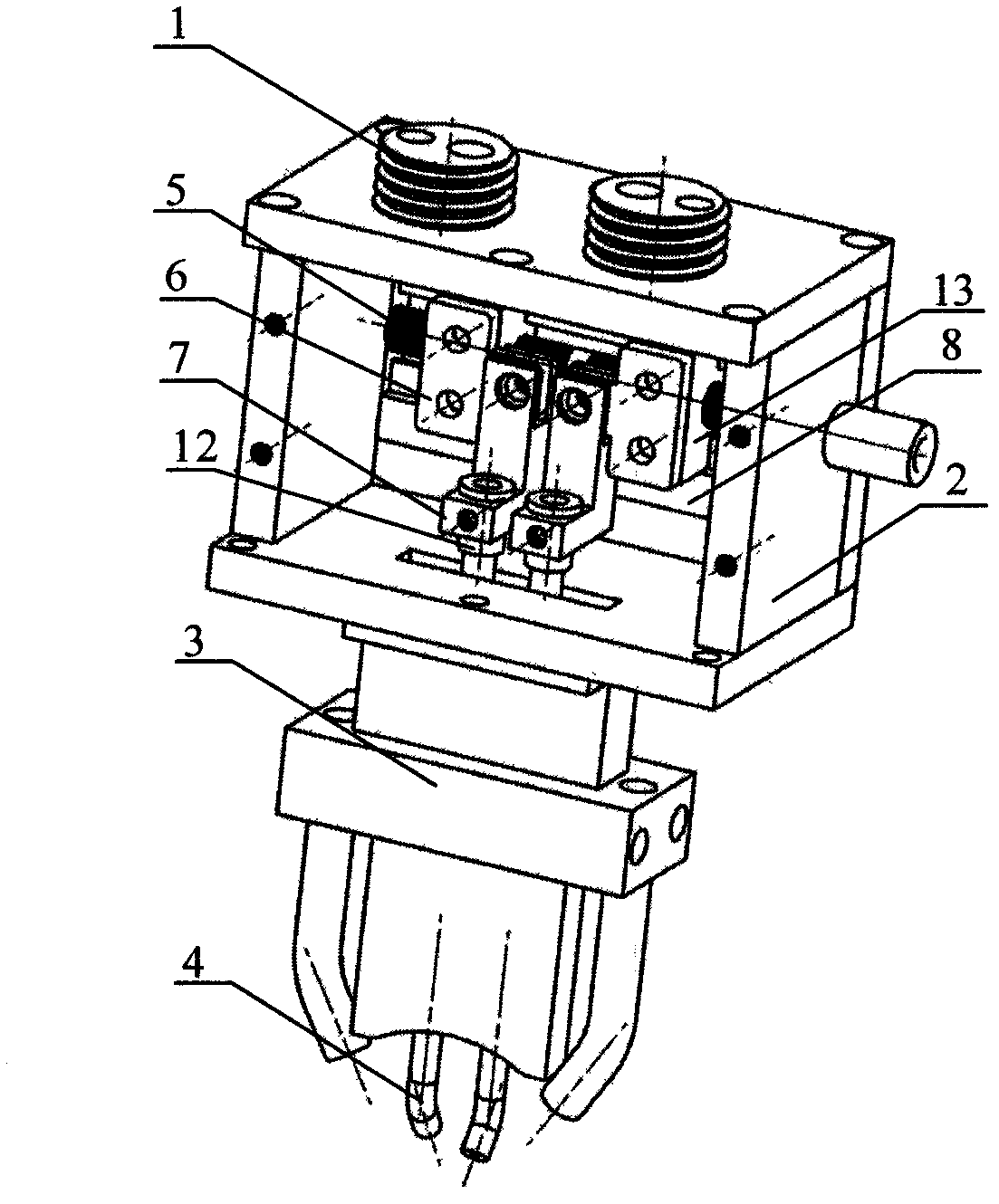

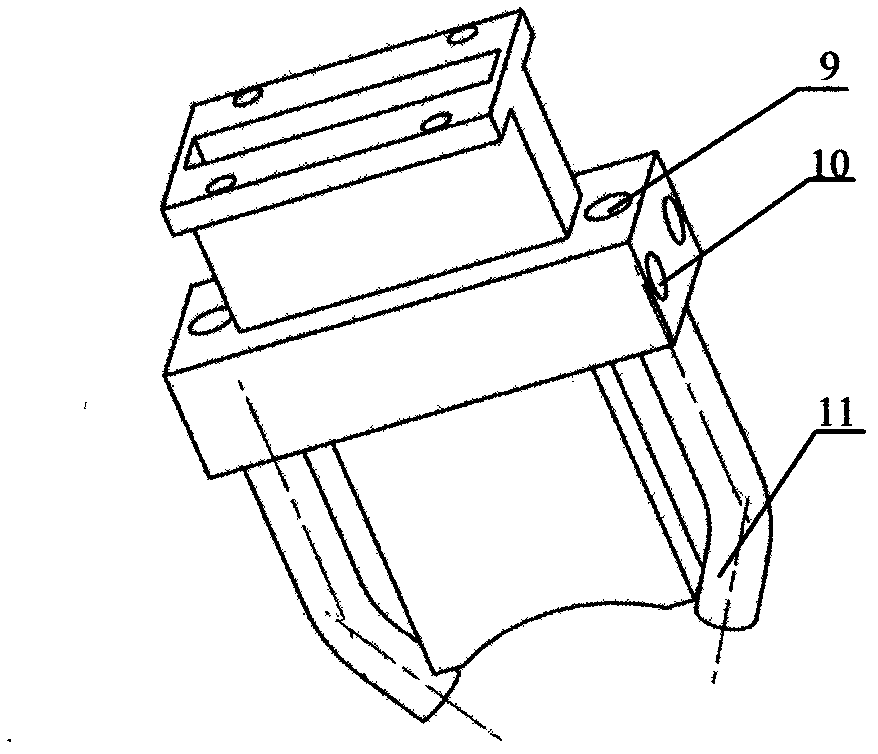

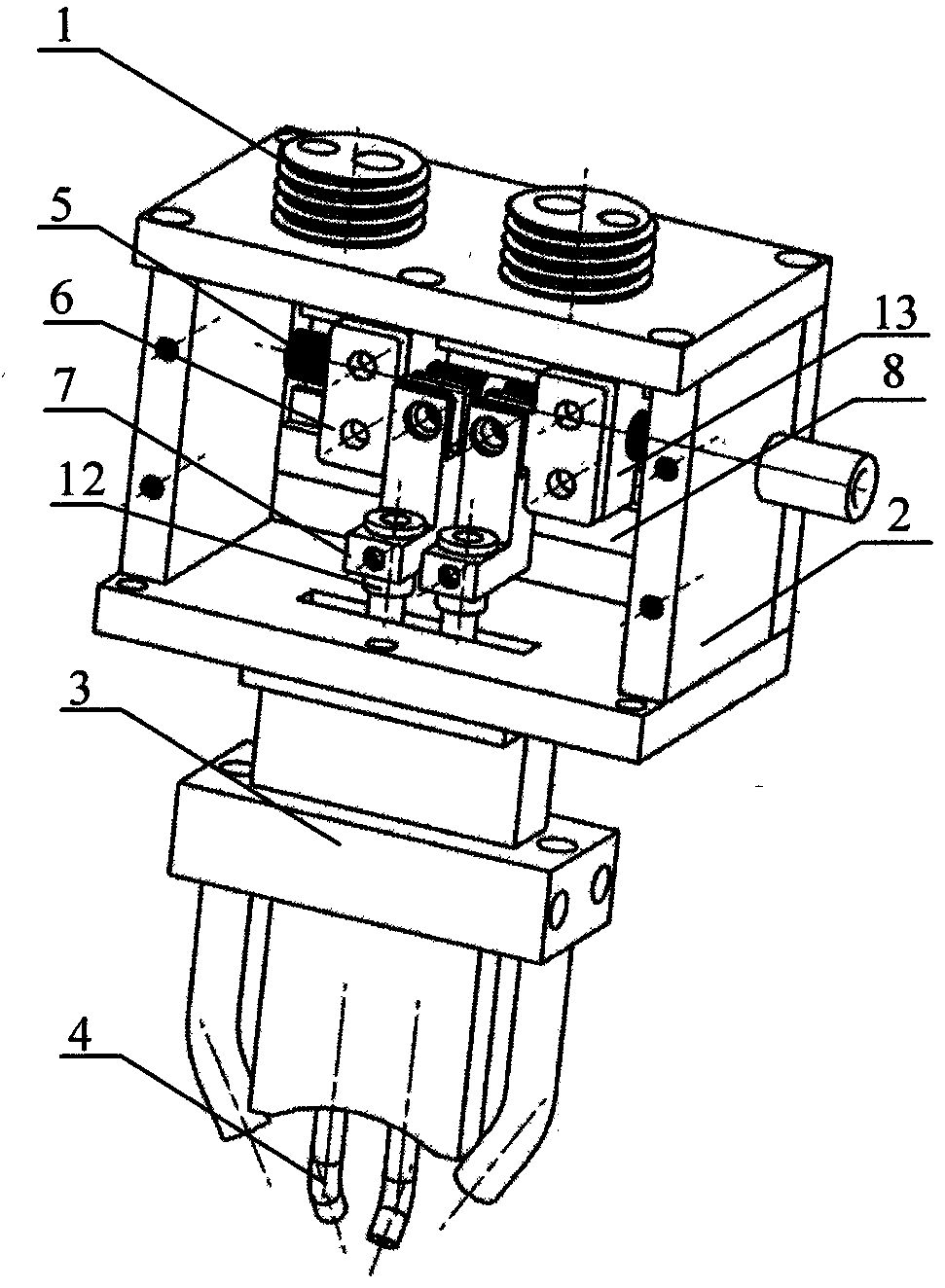

[0013] Example 1: Combining figure 1 , figure 2 , the present invention is a curved conductive tip type twin-wire narrow gap MIG / MAG welding torch, which is composed of a welding torch joint (1), a welding torch casing (2) and a three-channel plug-in narrow gap shielding gas nozzle (3), The welding torch joint (1) is connected to the welding torch casing (2), and the welding torch casing (2) is connected to the three-channel plug-in narrow-gap shielding gas nozzle (3).

[0014] The present invention also has the following technical characteristics:

[0015] The welding torch box (2) includes a guide rail (8), a slider (13), a screw (5), a T-shaped connector (6), an L-shaped connector (7), a conductive rod (12) and a curved The contact tip (4) and the lead screw (5) are connected with the slider (13) through two sets of positive and negative threads, which can transfer the rotary motion to the parallel movement of the slider. The guide rail (8) is fixed on the welding torch ...

Embodiment 2

[0018] Example 2: Combining figure 1 , figure 2 , the working process of the present invention: the two wire feeding tubes enter the welding torch box through the terminal and are respectively sent into the two conductive rods, and at the same time, the shielding gas enters the welding torch box through the shielding gas inlet of the terminal and passes through the main channel of the shielding gas nozzle. The welding area is protected. The two curved conductive tips are respectively installed on the two conductive rods, and the conductive rods are adjusted so that the two curved conductive tips point to the two side walls of the narrow gap groove respectively, and then the conductive rods are fixed with screws, and the two welding wires pass through the wire feeding tube from the two curved conductive tips. Stretch out, the two protruding welding wires have an included angle of 5-10 degrees with the two side walls of the narrow gap groove, which can ensure that the arc burn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com